Total-iron complexing flow cell with high open-circuit voltage

A technology of flow battery and iron complex, which is applied in the field of all-iron complex flow battery to achieve the effects of abundant reserves, increasing open circuit voltage and reducing battery cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

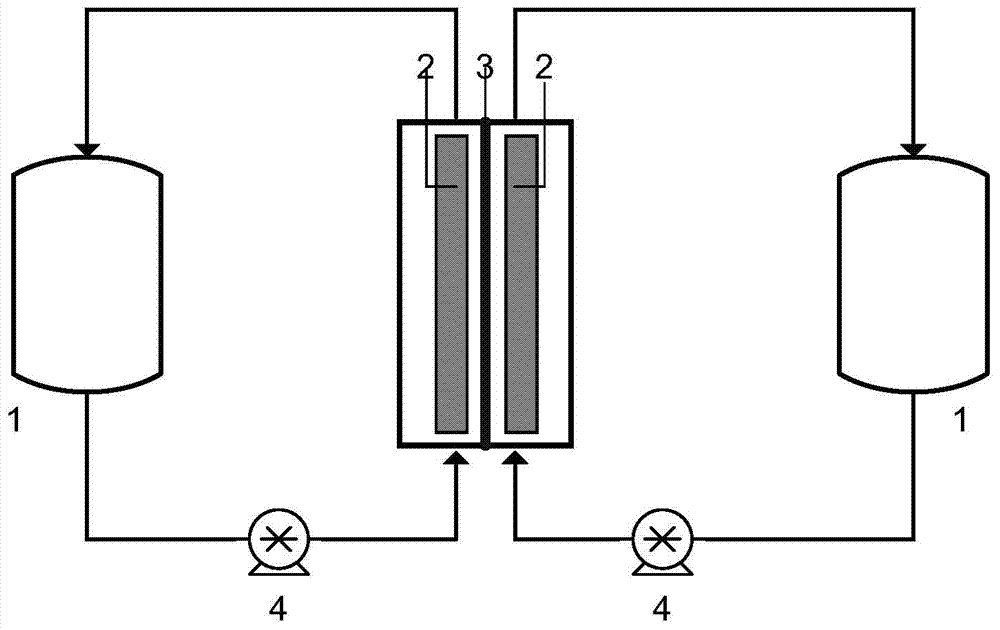

[0028] Weigh 2.7801g FeSO 4 .7H 2 O crystals dissolved in deionized water, in molar ratio FeSO 4 .7H 2 O:Phen:H 2 SO 4 Add Phen and 98%H for 1:3:10 2 SO 4 , electromagnetically stirred until dissolved, and configured as 100mL positive electrode electrolyte, wherein the concentration of Fe(II) / Phen complex is 0.1mol / L. Weigh 0.9997gFe 2 (SO 4 ) 3 .xH 2 O crystals dissolved in deionized water, in molar ratio Fe 2 (SO 4 ) 3 .xH 2 O:TEA:NaOH:NaCl is 1:16:20:8 Add TEA, NaOH and NaCl, electromagnetically stir until dissolved, configure 100mL negative electrode electrolyte, wherein the concentration of Fe(III) / TEA complex is 0.05mol / L. Put 60mL of positive and negative electrolytes in 2 liquid storage tanks respectively, according to figure 1 The shown assembly is an all-iron complex flow battery. Among them, the size of graphite felt electrode is 2×2×0.5cm, and the effective area of Nafion117 membrane is 4cm 2 . Carry out the battery charge and discharge test, ...

Embodiment 2

[0030] Weigh 5.5602g FeSO 4 .7H 2 O crystals dissolved in deionized water, in molar ratio FeSO 4 .7H 2 O:Phen:H 2 SO 4Add Phen and 98%H for 1:5:5 2 SO 4 , electromagnetically stirred until dissolved, and configured as 100mL anode electrolyte, wherein the concentration of Fe(II) / Phen complex is 0.2mol / L. Weigh 7.9976gFe 2 (SO 4 ) 3 .xH 2 O crystals dissolved in deionized water, in molar ratio Fe 2 (SO 4 ) 3 .xH 2 O:TEA:NaOH:NaCl is 1:5:7.5:1 Add TEA, NaOH and NaCl, electromagnetically stir until dissolved, configure 100mL negative electrode electrolyte, wherein the concentration of Fe(III) / TEA complex is 0.4mol / L. Put 35mL of positive and negative electrolytes in two liquid storage tanks respectively, according to figure 1 The shown assembly is an all-iron complex flow battery. Among them, the size of graphite felt electrode is 2×2×0.5cm, and the effective area of Nafion115 membrane is 4cm 2 . Carry out the battery charge and discharge test, the charge and...

Embodiment 3

[0032] Weigh 11.1204g FeSO 4 .7H 2 O crystals dissolved in deionized water, in molar ratio FeSO 4 .7H 2 O:Phen:H 2 SO 4 Add Phen and 98%H for 1:5:2.5 2 SO 4 , electromagnetically stirred until dissolved, and configured as 100mL positive electrode electrolyte, wherein the concentration of Fe(II) / Phen complex is 0.4mol / L. Weigh 7.9976gFe 2 (SO 4 ) 3 .xH 2 O crystals dissolved in deionized water, in molar ratio Fe 2 (SO 4 ) 3 .xH 2 O:TEA:NaOH:NaCl is 1:5:7.5:1 Add TEA, NaOH and NaCl, electromagnetically stir until dissolved, configure 100mL negative electrode electrolyte, wherein the concentration of Fe(III) / TEA complex is 0.4mol / L. Put 35mL of positive and negative electrolytes in two liquid storage tanks respectively, according to figure 1 The shown assembly is an all-iron complex flow battery. Among them, the size of graphite felt electrode is 2×2×0.5cm, and the effective area of Nafion115 membrane is 4cm 2 . Carry out the battery charge and discharge tes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com