Organic luminescence display device

A light-emitting display device, organic technology, applied in the direction of electrical solid-state devices, semiconductor devices, semiconductor/solid-state device manufacturing, etc., can solve the problems affecting carrier balance, restricting product development, limited high hole mobility materials, etc., and achieves a wide range of applications. The range of material selection and the effect of improving photoelectric performance

Active Publication Date: 2014-04-02

BEIJING VISIONOX TECH +1

View PDF3 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] At present, the industry usually adjusts the thickness of the hole injection layer (HIL, hole injection layer) to obtain the thickness of the organic layer that meets the optical path requirements, but the increased HIL thickness will lead to an increase in the driving voltage of the device and will also affect the carrier. Balance, which in turn affects the performance of the device such as efficiency and life

On the other hand, HIL needs to be matched with the subsequent hole transport layer (HTL, Hole transferring layer), which makes the choice of HTL materials smaller

Chinese patent CN101308863 discloses a material with high hole mobility as an auxiliary layer to adjust the resonance period of green light and red light, but the high hole mobility material selected by this solution is very limited, which limits the development of products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

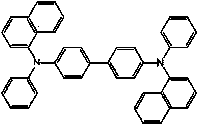

The invention discloses an organic luminescence display device. The organic luminescence display device comprises a substrate, a first electrode, a second electrode, an optical reinforcing layer and an organic layer, wherein the first electrode has reflection characteristics; the second electrode has semi-transmittance semi-reflection characteristics; the optical reinforcing layer is arranged on the second electrode; the organic layer is arranged between the first electrode and the second electrode, the organic layer comprises a hole-injection layer, a hole-transport layer, a luminescence layer and an electron transfer layer, the hole-injection layer is adjacent to the first electrode and arranged above the first electrode, the luminescence layer comprises a red light luminescence layer, a green light luminescence layer and a blue light luminescence layer, which are respectively arranged in a red pixel area, a green pixel area and a blue pixel area; and the organic luminescence display device also comprises an optical compensation layer which is arranged in a green light pixel area and a red light pixel area and between the hole-injection layer and the hole-transport layer, and the optical compensation layer is a structure with at least two layers.

Description

technical field [0001] The present invention relates to an organic light emitting display device with blue light, green light and red light pixels, in particular to an organic light emitting display device with an optical compensation layer in the red light pixel and green light pixel devices to meet the resonance requirements . Background technique [0002] OLED (Organic Light-Emitting Diode, organic light-emitting diode) display realizes color display by light-emitting devices of three colors: red, green, and blue. OLEDs can be divided into bottom-emitting devices (the outgoing light exits through the side of the substrate) and top-emitting devices (the exiting light exits away from the substrate side) according to the direction of the outgoing light. In order to obtain higher efficiency and brightness, AMOLED (Active Matrix / Organic Light Emitting Diode, Active Matrix Organic Light Emitting Diode) usually adopts a top emission structure. The top-emitting device includes ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01L51/50H01L51/54H01L27/32

CPCH10K50/11H10K2101/10H10K50/125H10K50/85

Inventor 刘嵩何麟

Owner BEIJING VISIONOX TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com