A Tooling for Trimming Pins in Ceramic Pillar Grid Arrays

A ceramic column grid array and tooling technology, which is applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as oxidation and pin skew, and achieve the effect of improving the accuracy and quality of orthopedics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] A tool for trimming pins in a ceramic column grid array, the tool includes a grinding tool and an orthopedic tool;

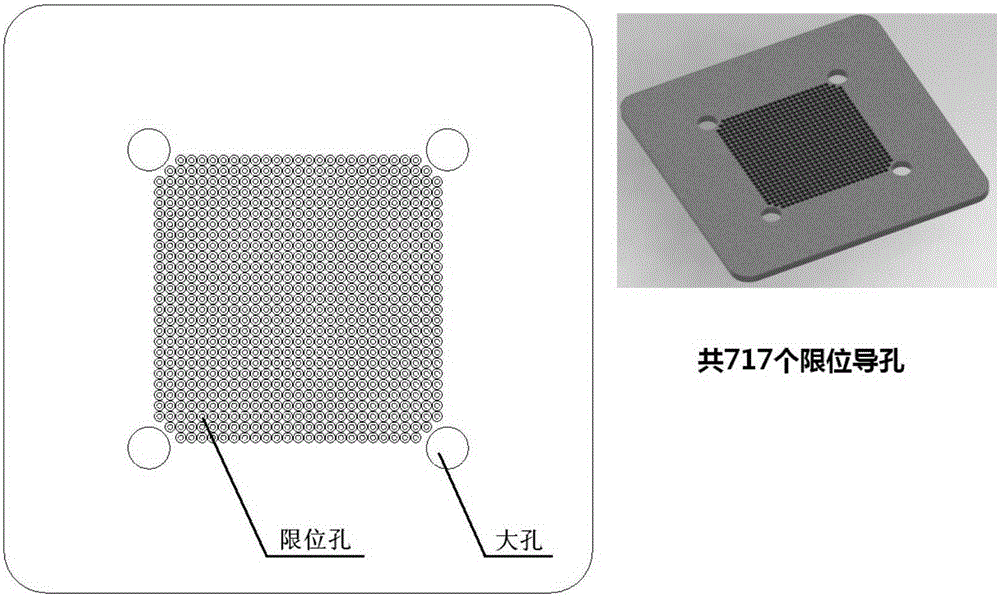

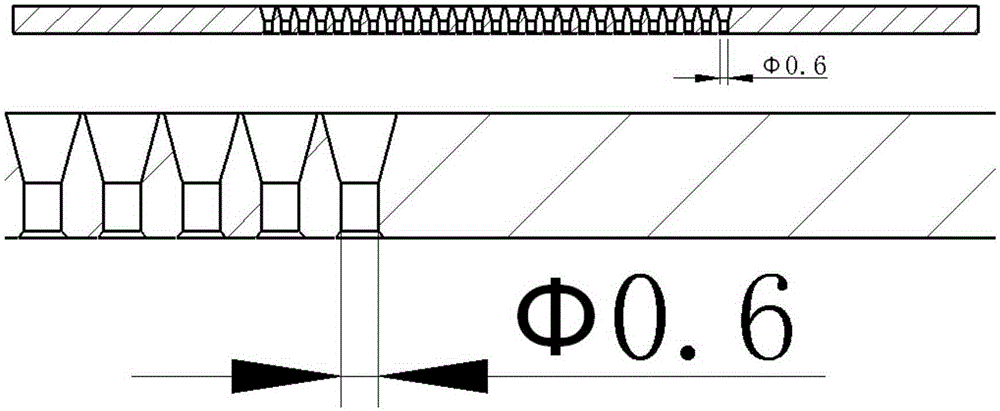

[0026] Such as figure 1 with figure 2 As shown, the orthopedic tooling is an orthopedic clamp, and there are 717 limit holes distributed in its center, and the distribution of the limit holes matches the position of the pins in the ceramic column grid array; the diameter of the limit holes is 0.6mm, 0.7 mm and 0.8mm, the distance between the limit holes is 1.27mm, one side of the limit hole is drilled with a 15° guide hole, and the depth is half of the overall depth of the limit hole;

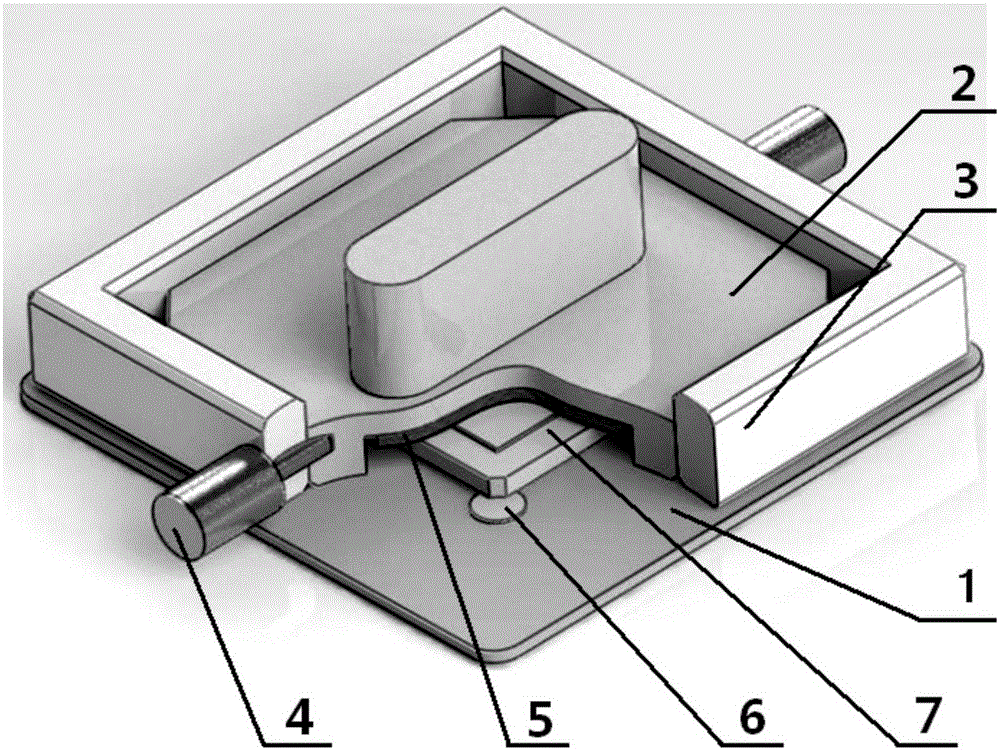

[0027] Such as image 3 with Figure 4 As shown, the grinding tooling includes a pressing block handle 2, a limit card plate combination, a locking pin 4, a sponge cushion 5 and an adjusting gasket 6;

[0028] The limit card plate combination includes a positioning frame 3 and a limit card plate 1;

[0029] There is a square working area in the center of the limit ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com