Belt sander on-line tension control device

A tension control and belt machine technology, which is used in belt grinders, workpiece feed motion control, manufacturing tools, etc., can solve the problem of reduced wire drawing yield, inaccurate control of wire grinding amount, and belt tension control. Insufficient precision and other problems, to achieve the effect of precise grinding control, improved yield, and improved control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

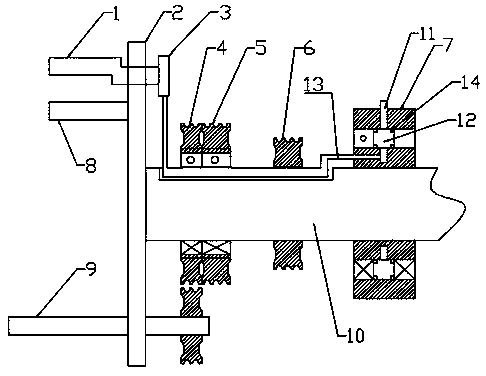

[0013] Such as figure 1 The online tension control device for the belt machine shown includes a main shaft 10 of the belt machine and a turntable 2 driven by the main shaft 10 of the belt machine. The main shaft 10 of the belt machine is powered by the rotating pulley 6 of the main shaft. The abrasive belt primary transmission pulley 4 and the abrasive belt secondary transmission pulley 5 transmit power, the abrasive belt primary transmission pulley 4 transmits power to the abrasive belt rotating shaft 9, and the rotating crankshaft 1 and the abrasive belt are respectively arranged on the opposite sides of the circle center on the turntable 2 The rotating shaft 9, the abrasive belt is a closed-loop body wound around the rotating crankshaft 1 and the abrasive belt rotating shaft 9;

[0014] The online tension control device also includes a rotating air sleeve 7, the outer side of the rotating air sleeve 7 is fixed on the bracket, and the inner side rotates with the main shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com