System and method for monitoring surface-pollution electrical conductivity of insulator

A technology for insulators and conductivity, applied in the system field of monitoring the conductivity of insulator surface pollution, can solve the problems of difficult correction coefficient, expensive equipment, complicated processing process, etc., and achieve the effects of good stability, convenient connection and simple measuring device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

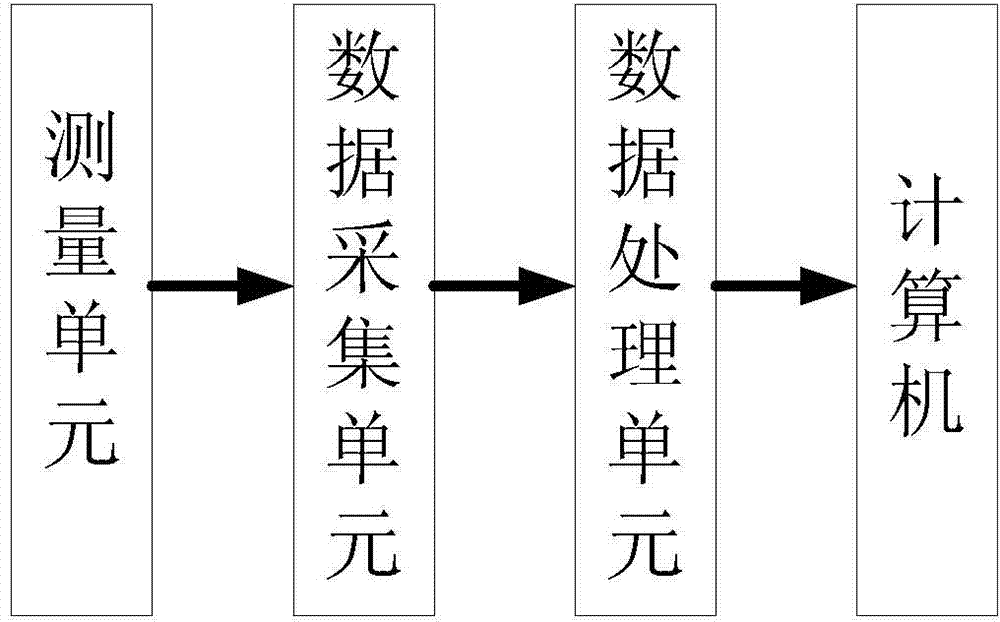

[0039] Such as figure 1 As shown, a system for monitoring the contamination conductivity of the surface of an insulator includes a measurement unit, a data acquisition unit, a data processing unit and a computer connected in sequence. The measurement unit, the data acquisition unit and the data processing unit are connected by wires, and the data processing unit and The computer is connected through a wireless communication network;

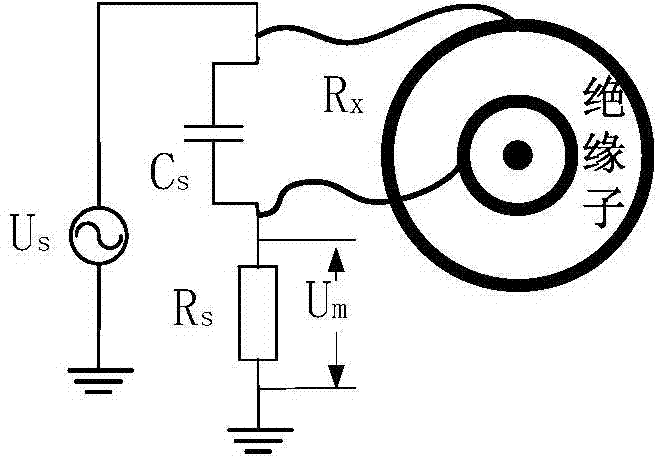

[0040] Such as image 3 As shown, the measurement unit consists of a signal source circuit Us, a fixed value resistor R s , Fixed value capacitor C s and the equivalent resistance R of insulator surface contamination x form, where the constant value capacitor C s Equivalent resistance R with insulator surface contamination x connected in parallel with the fixed value resistor R in turn s , The signal source circuit is connected in series;

[0041] The constant value resistor R s It consists of more than one resistor in series or in parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com