A Comprehensive Failure Judgment Method for Major Power Generation Equipment

A technology for power generation equipment and determination methods, which is applied in the testing, measuring devices, instruments and other directions of machines/structural components, and can solve problems such as complex working conditions, deterioration of tissue properties, and general manufacturing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1 :Hydrogen embrittlement and hydrogen bubbling failure mode and analysis

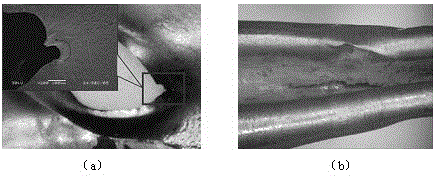

[0034] figure 1 Shown is the fracture appearance of a failed heat transfer titanium tube in a tube sheet in a heat exchanger of a large power generation equipment. It can be seen that the left side of the breach is oval, see figure 1 The shape of the inner wall of (a), and the edge is obviously concave from the outside to the inside, indicating that the outer wall of the heat transfer tube has been subjected to some kind of squeezing force. And there is brittle cracking on the outer wall of another failed heat transfer titanium tube, see figure 1 (b).

[0035] In order to find out the causes of the above-mentioned rare failure phenomena, the project innovatively implemented the following failure analysis strategies:

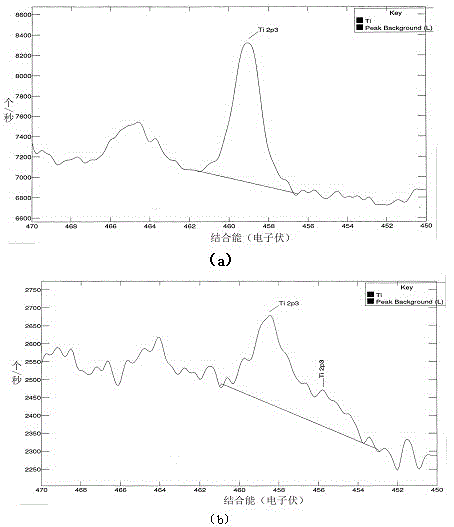

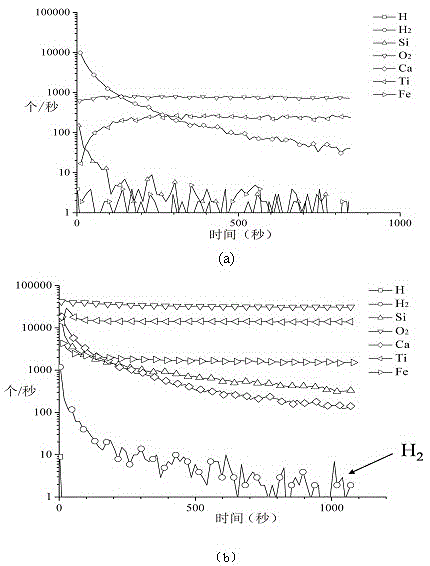

[0036] (1) X-ray photoelectron spectroscopy surface analysis. Using X-ray photoelectron spectroscopy analysis, it is determined that the Ti element on the surface of the in...

Embodiment 2

[0040] Example 2 : Failure morphology and analysis of mechanical micro-sags

[0041] It is found that the inner wall of the heat transfer tube of a heat exchanger has coin-shaped micro depressions ( Figure 5 (a)). After using scanning electron microscopy and energy spectrum analysis to observe and analyze the micro-area morphology of the circular fracture in the depression, see Figure 5 (b) It was quickly identified that this type of depression was caused by the excessively hard clamping force of the traction fixing head when the heat transfer tube was installed through the plate. Therefore, when the fluid medium in the heat transfer tube flows through the mechanical micro-depression, local turbulence occurs, and the micro-flow field changes. The fluid produces continuous vortex scouring centered on the surface of the depression, and gradually changes with the depression. As the depth becomes larger, the scouring and abrasion effect is intensified, and eventually the pipe wal...

Embodiment 3

[0043] Example 3 : Failure mode and analysis of fretting wear

[0044] Image 6 (a) Shows the rupture on the surface of the heat transfer tube under the support plate in a heat exchanger. It can be seen that there are obvious friction streaks on the outer wall of the tube, and there is also a long bending mechanical cut on the breach, which is obviously the result of accidental cuts when the heat transfer tube passes through the fixing hole of the support plate. At that time, the cut was not completely damaged, but it was exactly on the contact surface of the support plate. Therefore, when the heat exchanger was running, due to the fluctuation of the fluid medium, the heat transfer tube would definitely have irregular fretting wear with the support plate. Image 6 The scanning electron micrograph of (b) clearly shows that there is a ring-shaped wear surface generated by fretting abrasion with the support plate near the cut, and in addition to a layer of loosely distributed metal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com