Preparation process for oxidized cationic sizing starch

A technology for sizing starch and preparation process, which is applied in the directions of adding water repellents, paper, textiles and papermaking to achieve the effects of stable quality, reduced paper cost, and prevention of lint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

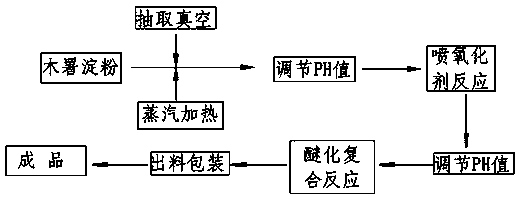

Image

Examples

Embodiment 1

[0026] (1) Oxidation reaction:

[0027] Get 1000 parts by weight of tapioca starch, put it into a dry reaction kettle and spray it into the starch with a volume concentration of 3-5% diluted lye, adjust the pH value to 9, then spray sodium hypochlorite, the amount of sodium hypochlorite is 5% of tapioca starch %, after fully stirring evenly, draw a vacuum, the vacuum degree is 300-500pa, heat to 60°C, and react for 2 hours.

[0028] (2), etherification complex reaction:

[0029] After the reaction of oxidized starch is finished, the vacuum of the dry process reactor is released, and the mixture of alkali and 3-chloro-2 hydroxypropyl trimethyl ammonium chloride is directly sprayed, and the substitution degree of oxidized cationic sizing starch is 0.01-0.02, The dosage of 3-chloro-2 hydroxypropyl trimethyl ammonium chloride is 3%-4% of tapioca starch, and the molar ratio of 3-chloro-2 hydroxypropyl trimethyl ammonium chloride and alkali is 1.5-1.7; After spraying the chemicals...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com