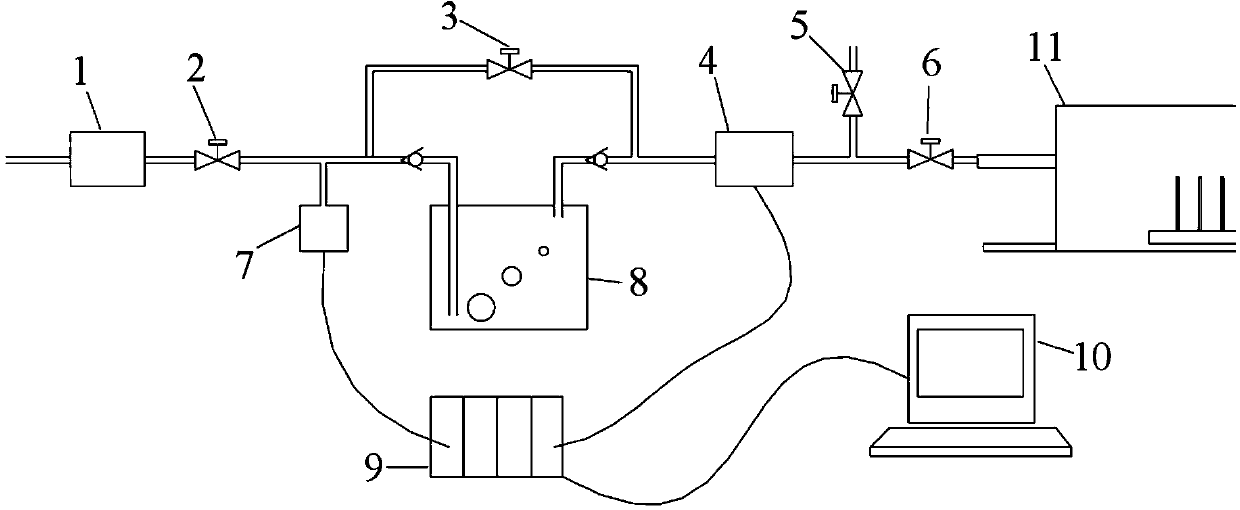

Source flow control system for negative-pressure diffusion furnace

A flow control and diffusion furnace technology, applied in the directions of diffusion/doping, crystal growth, post-processing, etc., can solve the problems of inadequate overload protection design, increased pressure on the source bottle, difficult to control, etc., to reduce the overall cost of equipment, The effect of improving the service life and reducing the degree of corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It is clear to those skilled in the art that the reaction chamber in the negative pressure diffusion furnace is always under negative pressure, for example, 100 mbar, when the diffusion process is performed. When the source flow (process gas) enters the reaction chamber under the guidance of the carrier gas, if it enters under normal pressure, the pressure difference will be large, so the source flow will increase significantly, and the source bottle will be under pressure Substantial increase, there is a risk of bursting. A source flow control system for a negative pressure diffusion furnace of the present invention is a source control part for an auxiliary negative pressure diffusion device. The main idea is to precisely control the pressure of the process gas that newly enters the reaction chamber, and under the premise of ensuring that the process gas that enters the reaction chamber enters at a certain temperature and flow rate, by reducing the pressure of the newl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com