A production method of grain-oriented silicon steel with excellent bottom quality

A technology of grain-oriented silicon steel and a production method, which is applied in the production field of grain-oriented silicon steel with excellent bottom layer quality, can solve the problems of not considering the influence of the bottom layer quality, difficult to obtain effects, insufficient and other problems, so as to reduce or eliminate point-like exposed gold defects, The effect of eliminating spot-like gold defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The chemical composition and weight percentage are: 3.15%Si; 0.040%C; 0.22%Mn; 0.021%S; 0.021%Als; 0.0090%N; ; The rest is Fe and unavoidable impurities of continuous casting slab heated at 1180 ℃, hot-rolled into a hot-rolled coil thickness of 2.3mm.

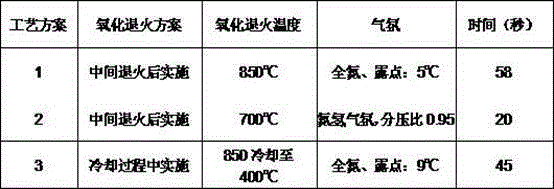

[0047] After normalized annealing, the hot-rolled coils are cold-rolled once to a thickness of 0.30mm and 0.27mm, then undergo continuous decarburization annealing and nitriding annealing, and are coated with an annealing separator with magnesium oxide as the main component, and then undergo an oxidation annealing process. high-temperature annealing, and the rest of the process is carried out as usual. The results of its implementation are shown in Table 1.

[0048] Table 1 The decarburization and nitriding annealing primary cold rolling method result list that the present embodiment and comparative examples all adopt

[0049]

Embodiment 2

[0051] The composition and weight percentage of the continuous casting slab are: 3.20%Si; 0.056%C; 0.08%Mn; 0.011%S; 0.030%AIs; 0.0085%N; %Ti; the rest is Fe and unavoidable impurities. After the billet is heated at 1200°C, it is hot rolled into a hot coil with a thickness of 2.3 mm.

[0052] After normalized annealing, hot-rolled coils are cold-rolled to a thickness of 0.23mm and 0.27mm, and then oxidized and annealed after continuous decarburization annealing or / and in the cooling stage of decarburization and nitriding treatment, and coated with magnesium oxide as the main component The annealing spacer, or / and use pure nitrogen atmosphere for oxidation annealing treatment in the first heating stage of high temperature annealing, and the other stage processes of high temperature annealing are carried out as usual. The results obtained after stretching, leveling annealing and insulating coating are shown in Table 2.

[0053] Table 2 The decarburization and nitriding anneali...

Embodiment 3

[0056] Continuous casting slab composition (weight percent): 0.033-36%C, 3.16-3.20%Si, 0.18-0.19%Mn, 0.0040-0.0060%S, 0.014-0.16%Als, 0.0086-0.0093%N, 0.48-0.50% Cu, the rest is Fe and unavoidable impurities. After heating at 1250°C, the continuous casting slab is hot-rolled into a hot-rolled coil with a thickness of 2.3mm. After pickling and cold rolling to 0.65mm, after complete decarburization annealing in the middle, part of the steel coils are oxidized and annealed. The parameters of the oxidation annealing treatment scheme are shown in Table 3. Then all steel coils were cold-rolled to a finished thickness of 0.30mm, and then recovered and annealed at 580°C. Some coils were subjected to oxidation annealing during recovery annealing. The scheme is shown in Table 4. Afterwards, an annealing release agent with magnesium oxide as the main component is coated, and its moisture content is controlled at 2.0-3.0%. During the high-temperature annealing and heating stage, some coi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com