Preliming reactor and method

A reactor and pre-ashing technology, which is applied in application, sucrose production, purification using alkaline earth compounds, etc., can solve problems such as greater impact on clarification efficiency, loss of sugar, changes in pre-ashed cane juice, etc., to ensure sucrose production and quality, Guaranteed rotation speed and effect, and the effect of reducing flow fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

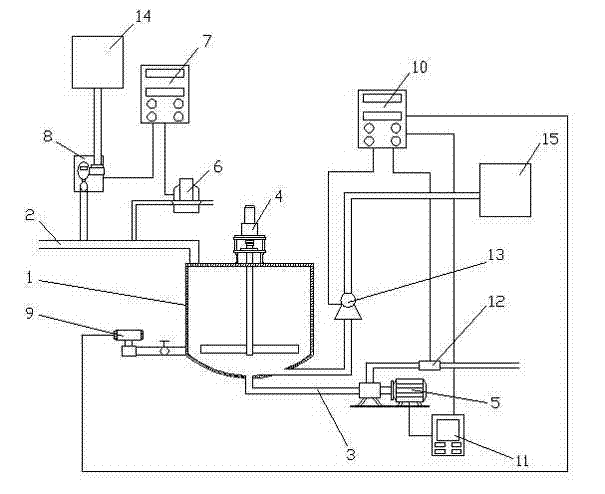

[0053] Such as figure 1 As shown, the preash reactor provided in this embodiment includes a cylinder body 1, a juice inlet pipe 2, a juice outlet pipe 3, a stirring device 4, a pH control device, a flow control device, a phosphoric acid adder 13 and a frequency conversion juice outlet pump 5;

[0054] The frequency conversion juice pump 5 communicates with the cylinder body 1 through the juice outlet pipe 3;

[0055] The pH control device detects the pH of the sugarcane juice at the outlet of the juice inlet pipe 2, and controls the pH of the sugarcane juice entering the cylinder 1 by controlling the amount of lime milk added;

[0056] The flow control device detects the liquid level information in the cylinder 1 and the juice flow rate of the juice outlet pipe 3, controls the speed of the frequency conversion juice outlet pump 5 according to the liquid level information and the juice flow rate, and transmits the control signal according to the juice flow rate To phosphoric a...

Embodiment 2

[0075] The present embodiment pre-ashing method comprises the following steps:

[0076] During the squeezing process before the pre-ashing process, the pH of the sugarcane juice output by controlling the squeezing process is 6.8;

[0077] a. The pH control device presets the pH control range parameters, detects the pH of the sugarcane juice in the juice inlet pipe, calculates the amount of lime milk that needs to be added in real time according to the difference between the pH value of the sugarcane juice and the preset value, and controls the pH of the sugarcane juice in the juice inlet pipe to be 7.5 ;

[0078]b. The flow control device detects the flow of sugarcane juice in the juice pipe through the flow detector, and A / D converts the flow information into a flow value signal, transmits it to the flow controller, compares it with the preset flow value, and passes the calculation result through The D / A is converted into a current signal and sent to the juice frequency conv...

Embodiment 3

[0082] The present embodiment pre-ashing method comprises the following steps:

[0083] During the squeezing process before the pre-ashing process, the pH of the sugarcane juice output by controlling the squeezing process is 8.0;

[0084] a. The pH control device presets the pH control range parameters, detects the pH of the sugarcane juice in the juice inlet pipe, calculates the amount of lime milk that needs to be added in real time according to the difference between the pH value of the sugarcane juice and the preset value, and controls the pH of the sugarcane juice in the juice inlet pipe to be 9.5 ;

[0085] b. The flow control device detects the flow of sugarcane juice in the juice pipe through the flow detector, and A / D converts the flow information into a flow value signal, transmits it to the flow controller, compares it with the preset flow value, and passes the calculation result through The D / A is converted into a current signal and sent to the juice frequency con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com