Syrup

A technology for syrup and rock sugar, which is applied in the fields of sucrose production, sugar production, and sugar juice purification, etc. It can solve the problems of increasing capital occupation of enterprises, obvious burnt smell, and disrupting market order, so as to improve production efficiency and economic efficiency. Benefits, the effect of improving the comprehensive utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of syrup, it is the syrup obtained after the mother liquor after the crystallized rock sugar has been crystallized in the process of preparing rock sugar is activated carbon;

[0035] The preparation method is:

[0036] (1) Dilute the mother liquor to a Brix of 47%;

[0037] (2) Insulation deodorization and decolorization: add the diluted mother liquor into the deodorization tank, add 0.5% activated carbon of the mother liquor mass into the deodorization tank, control the temperature at 63°C, and keep it for 40 minutes;

[0038] (3) Filtration: filter the mother liquor after heat preservation, deodorization and decolorization;

[0039] (4) Concentration: Concentrate the filtrate obtained in step (3) until the Brix is 60% to 70%.

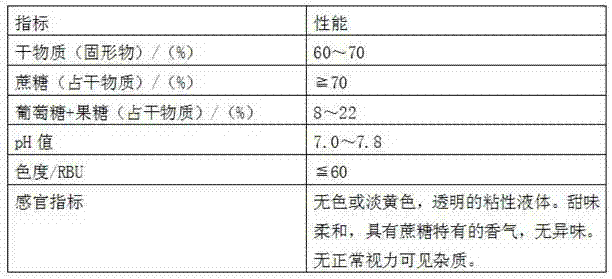

[0040] The properties of the syrup prepared in this embodiment are shown in Table 1 below.

[0041] Table 1

[0042]

Embodiment 2

[0044] The invention relates to syrup, which is the syrup obtained by sulfur bleaching the mother liquor after crystallization of single crystal rock sugar in the process of preparing rock sugar, and then adsorbing by active carbon.

[0045] The preparation method is:

[0046] (1) diluting the mother liquor to a Brix of 48%;

[0047] (2) Perform sulfur bleaching on the diluted mother liquor, the sulfur bleaching time is 3 seconds, the sulfur bleaching temperature does not exceed 75°C, and the pH value of the mother liquor is not lower than 5;

[0048] (3) Introduce the sulfur-bleached mother liquor into the deodorization tank, add activated carbon and filter aid, keep warm in the deodorization tank at 65°C and stir and mix for 50 minutes to obtain carbon-containing syrup, and filter the carbon-containing syrup with a plate and frame filter press Filter to obtain the clear juice, and concentrate the clear juice until the Brix is 75%;

[0049] The addition of activated carbo...

Embodiment 3

[0054] A kind of syrup, it is the syrup obtained after sulfur bleaching the mother liquor after the crystallization of single crystal rock sugar in the process of producing rock sugar, then carrying out active carbon adsorption, and then using decolorizing resin to absorb;

[0055] The preparation method is:

[0056] (1) diluting the mother liquor to a Brix of 48%;

[0057] (2) Perform sulfur bleaching on the diluted mother liquor, the sulfur bleaching time is 3 seconds, the sulfur bleaching temperature does not exceed 75°C, and the pH value of the mother liquor is not lower than 5;

[0058] (3) Introduce the sulfur-bleached mother liquor into the deodorization tank, add activated carbon and filter aid, keep warm in the deodorization tank at 65°C and stir and mix for 50 minutes to obtain carbon-containing syrup, and filter the carbon-containing syrup with a plate and frame filter press Filter to obtain clear juice;

[0059] The addition of activated carbon is 0.5% of the qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com