Structure grease containing eicosatetraenoic acid and preparation method thereof

A technology of eicosatetraenoic acid and structured oils, which is applied in the field of edible oils and fats and can solve the problems of low conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

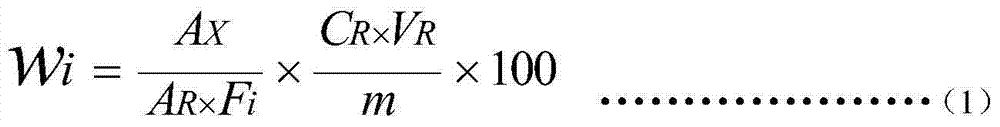

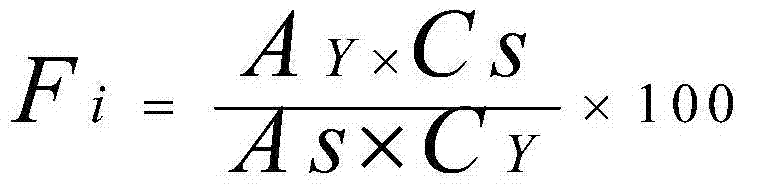

Method used

Image

Examples

Embodiment 1

[0027] In the present embodiment, the preparation method of structured grease comprises the following steps:

[0028] (1) Enzymatic transesterification of raw oil and eicosatetraenoic acid donor in the presence of specific Sn-1,3 lipase;

[0029] The aforementioned raw oil is lard, the donor of eicosatetraenoic acid is ethyl eicosatetraenoate, and the weight ratio of the donor of eicosatetraenoic acid to the raw oil is 2:1.

[0030] During the reaction, the raw oil and the eicosatetraenoic acid donor are mixed, and stirring can be carried out during the reaction to make the mixing more complete.

[0031] In this step (1), the dosage of specific Sn-1,3 lipase is 5% of the total weight of raw oil and eicosadonic acid donor, the reaction temperature is 70° C., and the reaction time is 3 hours.

[0032] (2) After the enzymatic transesterification reaction, removing the specific Sn-1,3 lipase to obtain an intermediate product;

[0033] In this step (2), the specific Sn-1,3 lipase...

Embodiment 2

[0039] In the present embodiment, the preparation method of structured grease comprises the following steps:

[0040] (1) Enzymatic transesterification of raw oil and eicosatetraenoic acid donor in the presence of specific Sn-1,3 lipase;

[0041] The above-mentioned raw material oil is palm oil, the donor of eicosatetraenoic acid is ethyl eicosatetraenoate, and the weight ratio of the donor of eicosatetraenoic acid to the raw oil is 2:1.

[0042] During the reaction, the raw oil and the eicosatetraenoic acid donor are mixed, and stirring can be carried out during the reaction to make the mixing more complete.

[0043] In this step (1), the dosage of specific Sn-1,3 lipase is 8% of the total weight of raw oil and eicosadonic acid donor, the reaction temperature is 60° C., and the reaction time is 3 hours.

[0044] (2) After the enzymatic transesterification reaction, removing the specific Sn-1,3 lipase to obtain an intermediate product;

[0045] In this step (2), the specific...

Embodiment 3

[0051] In the present embodiment, the preparation method of structured grease comprises the following steps:

[0052] (1) Enzymatic transesterification of raw oil and eicosatetraenoic acid donor in the presence of specific Sn-1,3 lipase;

[0053] The above-mentioned raw material oil is lard, and the donor of eicosatetraenoic acid is a mixture of methyl eicosatetraenoate and ethyl eicosatetraenoate (wherein methyl eicosatetraenoate and eicosatetraenoate The weight of ethyl enoate accounts for half each), and the weight ratio of eicosatetraenoic acid donor and raw oil is 3:1.

[0054] During the reaction, the raw oil and the eicosatetraenoic acid donor are mixed, and stirring can be carried out during the reaction to make the mixing more complete.

[0055] In this step (1), the dosage of the specific Sn-1,3 lipase is 1% of the total weight of the raw oil and the eicosadonic acid donor, the reaction temperature is 75° C., and the reaction time is 6 hours.

[0056] (2) After the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com