Zero Degree Wine Preparation System

A technology for preparing system and wine, applied in the field of zero-degree wine preparation system and distiller, can solve the problems of loss of wine quality characteristics, loss of aroma substances, etc., and achieve the effects of retaining quality characteristics, low production cost, and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

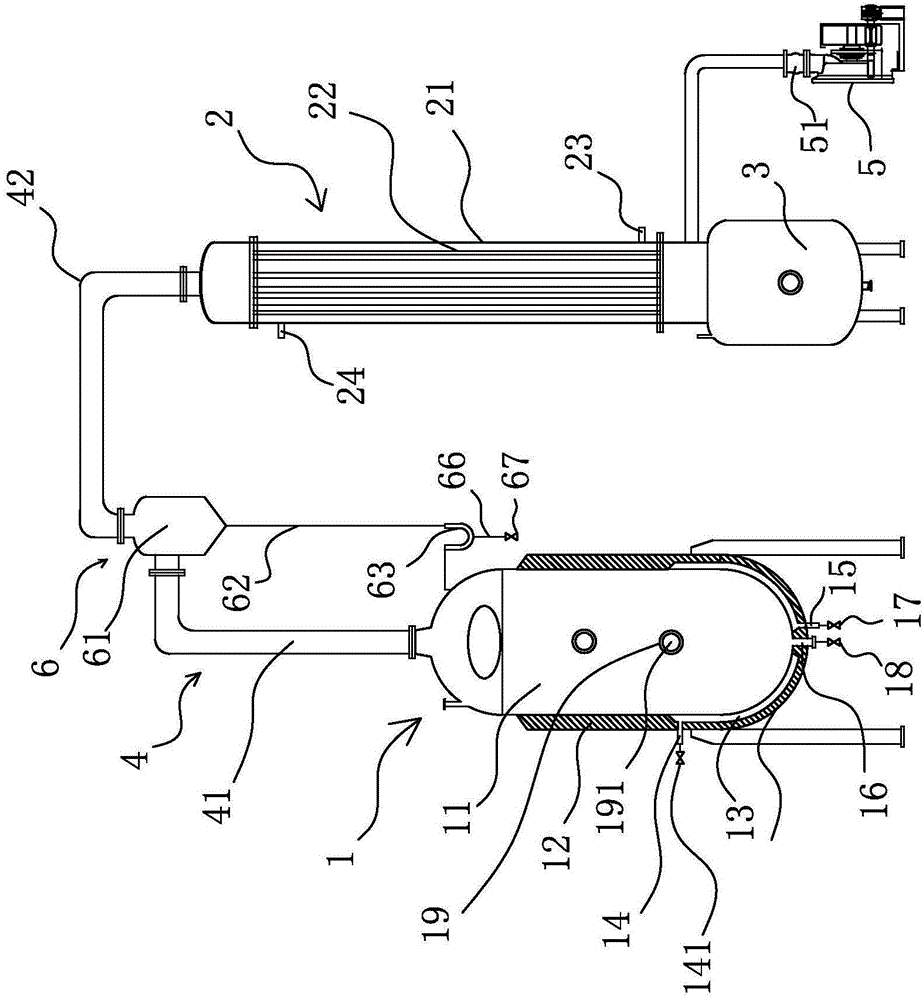

[0020] Such as figure 1 As shown, a zero-degree wine preparation system, the system includes a raw wine distillation device 1, a condenser 2 and an ethanol storage tank 3, the raw wine distillation device 1 is connected to the condenser 2 through a transmission pipeline 4, and the condenser 2 is connected with the ethanol storage tank 3, a vacuum pump 5 is connected to the condenser 2, at least one aroma substance recovery device 6 is connected in series on the transmission pipeline 4, and the aroma substance recovery device 6 is connected with the raw wine distillation Device 1 is connected. This system adopts the principle of vacuum distillation of ethanol, so that ethanol is distilled quickly at low temperature, thereby reducing the ethanol content of wine, because during the distillation process, the low-boiling aromatic substances in wine will also be vaporized together with ethanol to volatilize, aromatic substances The recovery device 6 has the effect of recovering low...

Embodiment 2

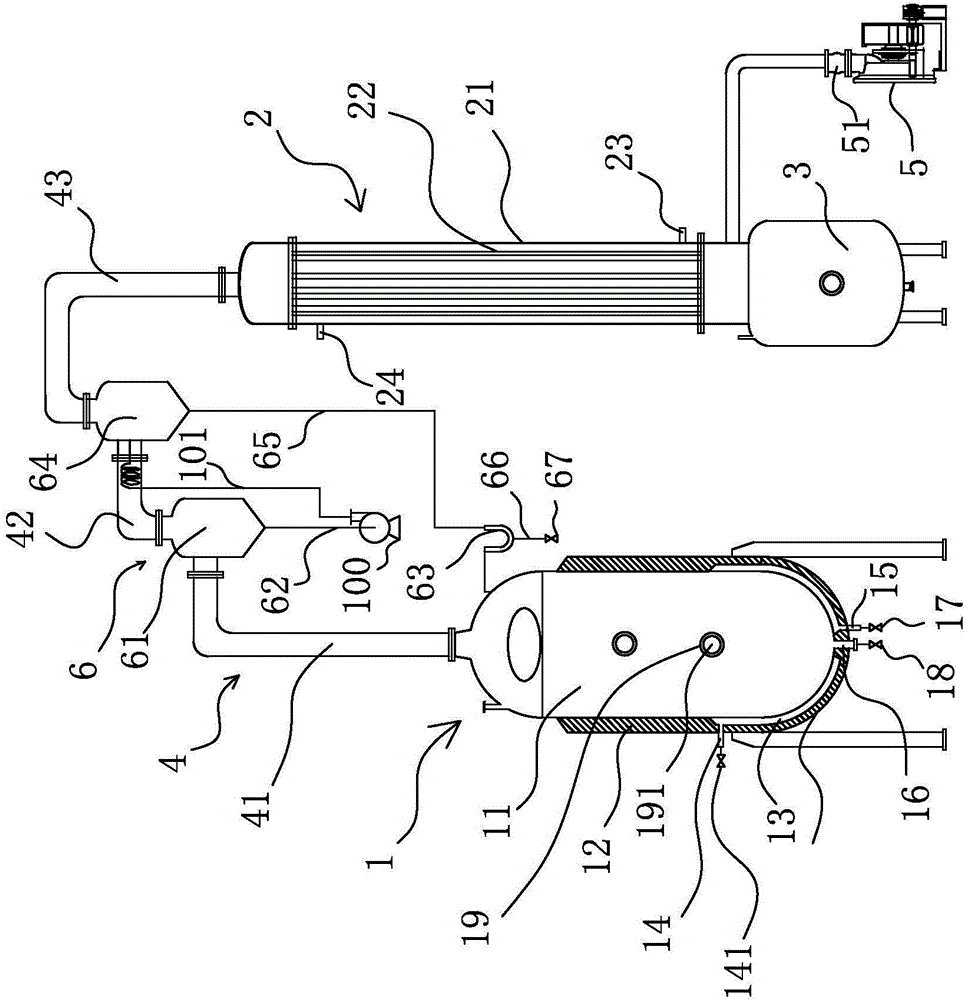

[0029] The structure and working principle of this embodiment are basically the same as those of Embodiment 1, the difference is that the aroma substance recovery device 6 includes a first recovery tank 61 and a second recovery tank 64, and the transmission pipeline 4 includes a The first pipe body 41 at the top and the side of the first recovery tank 61, the second pipe body 42 connecting the top of the first recovery tank 61 and the side of the second recovery tank 64, and the top of the second recovery tank 64 and the top of the condenser 2 The third pipe body 43, the bottom of the first recovery tank 61 is connected to the feed port of the delivery pump 100 with the first return pipe 62, and the discharge port of the delivery pump 100 is connected to the second recovery tank 64 through the delivery pipe 101, the delivery The material pipe 101 penetrates into the second pipe body 42 and connects to the second recovery tank 64. The bottom of the second recovery tank 64 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com