Method for synthesizing solution-type rare-earth rubber catalyst

A rare earth rubber and catalyst technology, applied in the field of rare earth rubber catalyst synthesis, can solve the problems of poor fluidity, heterogeneity, disadvantage and the like, and achieve the effect of simple process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

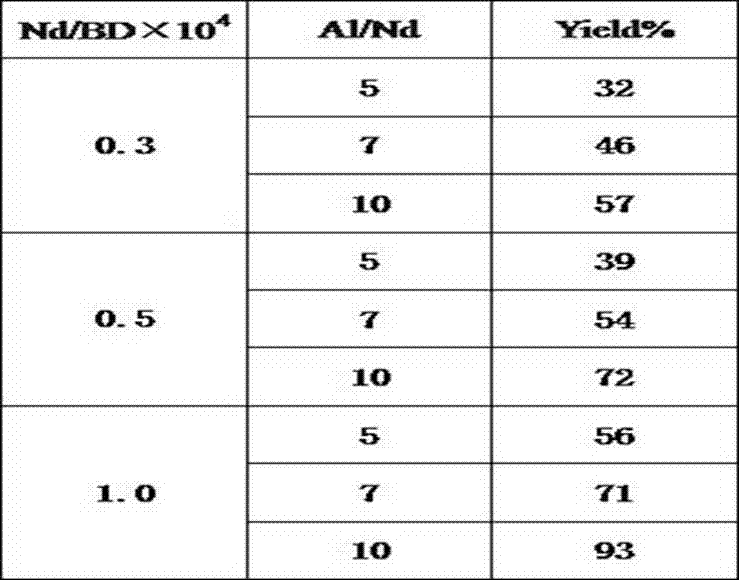

Embodiment 1

[0023] Use neodymium trioxide and hydrochloric acid to prepare an aqueous solution of neodymium trichloride with a concentration of 1.14 mol / L; use hexane to prepare a solution of P507 with a concentration of 0.35 mol / L; use distilled water to prepare an aqueous solution of sodium hydroxide with a concentration of 4.97 mol / L.

[0024] Take 2 L of P507 hexane solution in a 10 L container, add 2 L of hexane, then add 140 mL of sodium hydroxide solution under stirring, and stir and react at 50°C for 30 min to obtain a saponified solution. Then 205 mL of neodymium trichloride solution was added, and the reaction was rapidly stirred at room temperature for 30 min, and 1 L of hexane was added when the reaction was carried out for 10 min. Neodymium organophosphate was formed during the reaction, and the solution became obviously viscous, and stratification occurred after the stirring was stopped. The upper layer was a slightly purple viscous substance, and the lower layer was a clear ...

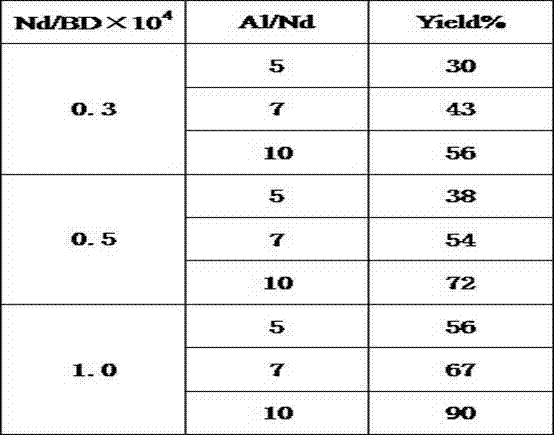

Embodiment 2

[0027] Use neodymium trioxide and hydrochloric acid to prepare an aqueous solution of neodymium trichloride with a concentration of 1.14 mol / L; prepare a P204 solution with a concentration of 0.36 mol / L with hexane; prepare an aqueous solution of sodium hydroxide with a concentration of 4.97 mol / L with distilled water.

[0028] Take 2 L of P204 hexane solution in a 10 L container, add 2 L of hexane, then add 145 mL of sodium hydroxide solution under stirring, and stir and react at 50°C for 30 min to obtain a saponified solution. Then 210 mL of neodymium trichloride solution was added, and the reaction was rapidly stirred at room temperature for 30 min, and 1 L of hexane was added when the reaction was carried out for 10 min. Neodymium organophosphate was formed during the reaction, and the solution visibly became viscous, and stratification occurred after the stirring was stopped. The upper layer was a slightly purple viscous substance, and the lower layer was a clear and trans...

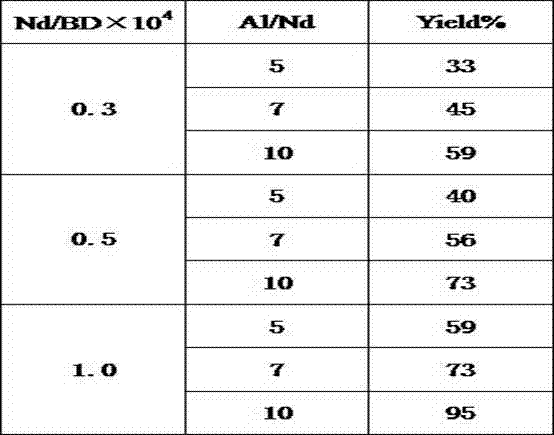

Embodiment 3

[0031] Use neodymium trioxide and hydrochloric acid to prepare an aqueous solution of neodymium trichloride with a concentration of 1.14 mol / L; use hexane to prepare a solution of P507 with a concentration of 0.35 mol / L; use distilled water to prepare an aqueous solution of sodium hydroxide with a concentration of 4.97 mol / L.

[0032]Take 2 L of P507 hexane solution in a 10 L container, add 1.65 L of hexane, then add 140 mL of sodium hydroxide solution under stirring, and stir and react at 50°C for 30 min to obtain a saponified solution. Then 205 mL of neodymium trichloride solution was added, and the reaction was rapidly stirred at room temperature for 30 min, and 1 L of hexane was added when the reaction was carried out for 10 min. Neodymium organophosphate was formed during the reaction, and the solution became obviously viscous, and stratification occurred after the stirring was stopped. The upper layer was a slightly purple viscous substance, and the lower layer was a clea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com