Low-density high-strength self-insulation ceramsite hollow block and production method thereof

A hollow block and high-strength technology, which is applied in the field of high-strength self-insulating ceramsite hollow blocks and low density, can solve the problems that thermal performance cannot meet the requirements of self-insulation function, and achieve increased strength, surface tension, The effect of improving thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1. A low-density, high-strength self-insulating ceramsite hollow block is composed of the following components in parts by weight, wherein: cement: 1, ceramsite: 1, slag: 0.56, Stone powder: 0.56, sand: 0.33, modifier: 0.15, water: 0.55;

[0053] Described modifying agent is polyvinyl acetate;

[0054] The ceramsite is grade 400-500, and the particle size distribution is 5-12mm.

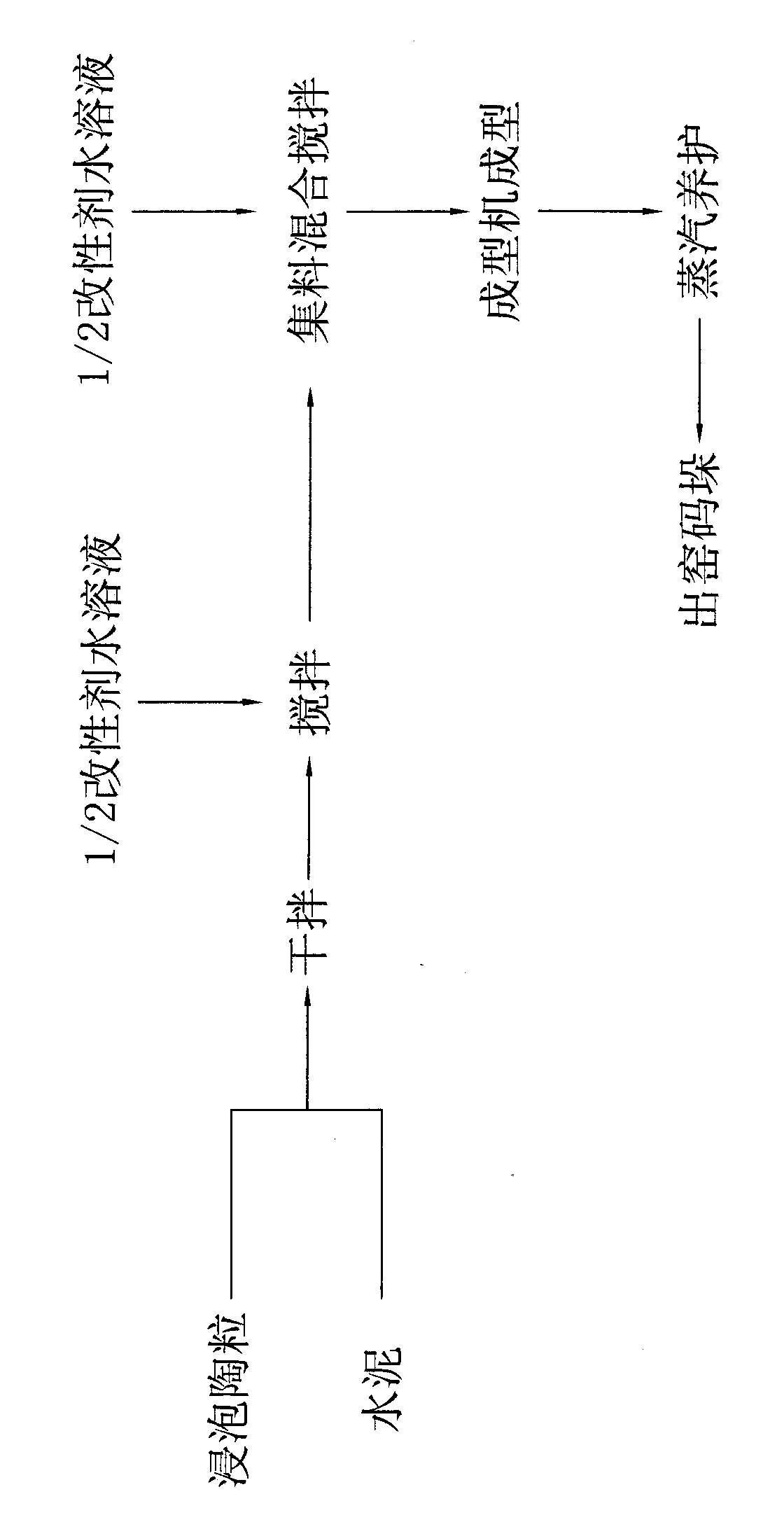

[0055] Its specific production method is as follows:

[0056] A. Soak the ceramsite in water for 24 hours to make it fully absorb water, then drain the water for later use;

[0057] B, dissolving the modifying agent in water to prepare an aqueous modifying agent solution;

[0058] C. Send the ceramsite and cement into the mixer for dry mixing. After mixing evenly, add 1 / 2 modifier aqueous solution and mix into ceramsite mortar so that the cement particles can fully cover the ceramsite. Then add slag, stone powder and sand and stir together. During the process, add the remaining ...

Embodiment 2

[0062] Embodiment 2. A low-density, high-strength self-insulating ceramsite hollow block is composed of the following components, the components are parts by weight, wherein: cement: 1, ceramsite: 1, slag: 0.56, Stone powder: 0.56, sand: 0.33, modifier: 0.15, water: 0.55;

[0063] Described modifying agent is polyvinyl acetate;

[0064] The ceramsite is grade 400-500, and the particle size distribution is 5-12mm.

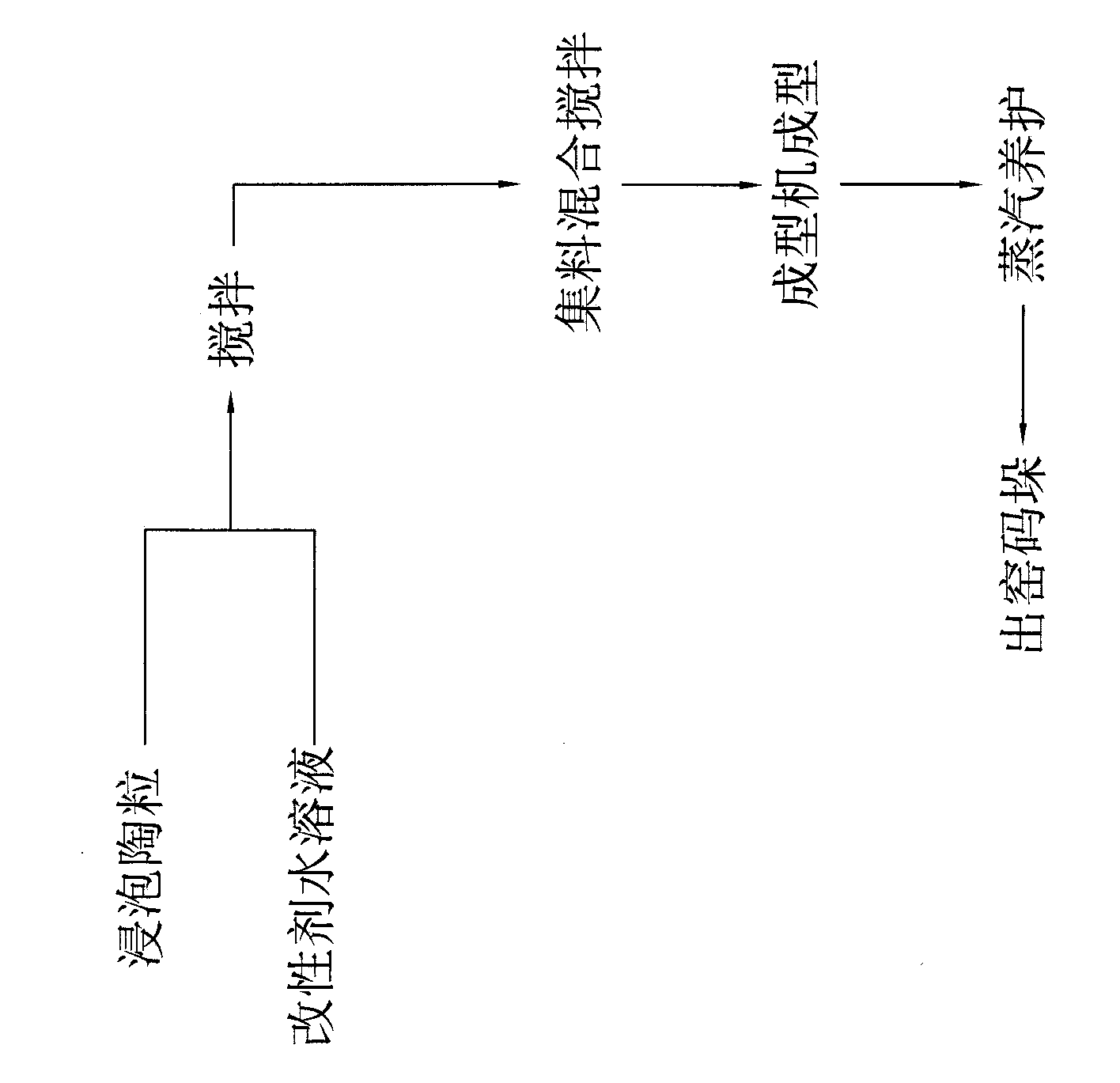

[0065] Its specific production method is as follows:

[0066] A. Soak the ceramsite in water for 24 hours to make it fully absorb water, then drain the water for later use;

[0067] B, dissolving the modifying agent in water to prepare an aqueous modifying agent solution;

[0068] C. Soak the drained ceramsite in the modifier solution and stir for 1 minute;

[0069] D. Send cement, slag, stone powder, and sand into the mixer and mix evenly, then add the ceramsite together with the soaking solution into the mixer and mix evenly. During the mixing process, add wat...

Embodiment 3

[0073] Embodiment 3. A low-density, high-strength self-insulating ceramsite hollow block is composed of the following components in parts by weight, wherein: cement: 1, ceramsite: 1, slag: 0.56, Stone powder: 0.56, sand: 0.33, modifier: 0.15, water: 0.55;

[0074] Described modifying agent is polyvinyl acetate;

[0075] The ceramsite is grade 400-500, and the particle size distribution is 5-12mm.

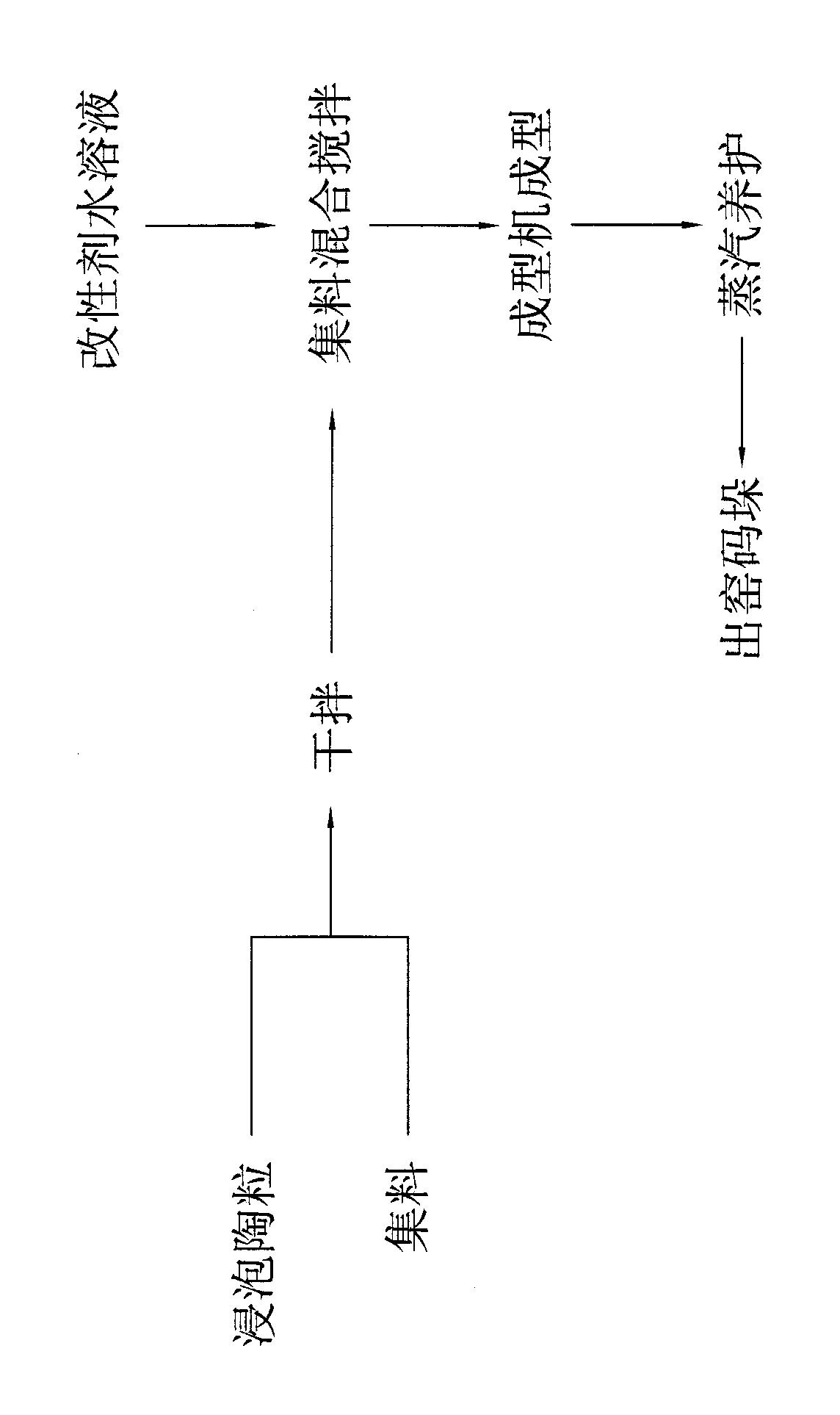

[0076] Its specific production method is as follows:

[0077] A. Dissolving modifier in water to prepare modifier aqueous solution;

[0078] B. Soak the ceramsite in water for 24 hours to make it fully absorb water, then drain the water for later use;

[0079] C. Send cement, slag, stone powder, and sand into the mixer and mix evenly, then send the ceramsite into the mixer and mix evenly, then add the modifier aqueous solution into the mixer and mix evenly. During the mixing process, add water according to the dry humidity of the material. Control the dry humidity of the mixed m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com