Ammonia distillation device and technology by mother liquor and total ash powder with alkaline method

An ammonia-alkali method and mother liquor technology, which is applied in the ammonia-alkali method mother liquor whole ash powder ammonia steaming device and process field, can solve the problems of fluctuating tower conditions, unable to make full use of quicklime digestion reaction heat, complicated operation, etc., and avoid back-mixing and reconciliation. The effect of full utilization of liquid and heat of digestion and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

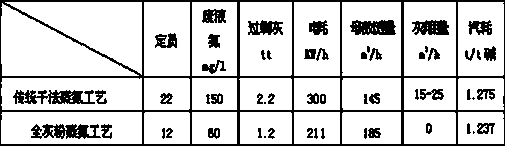

Embodiment 1

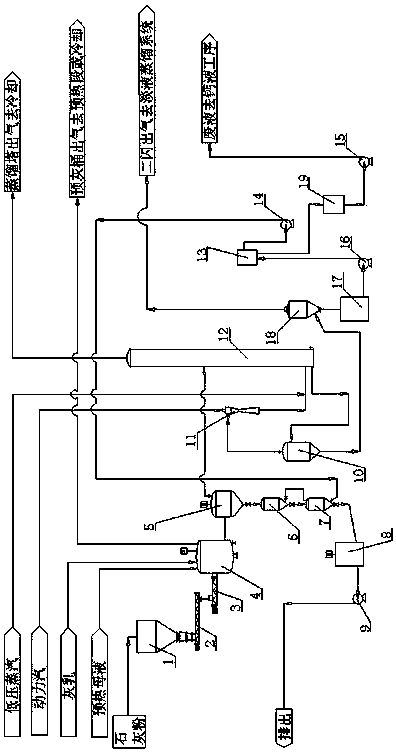

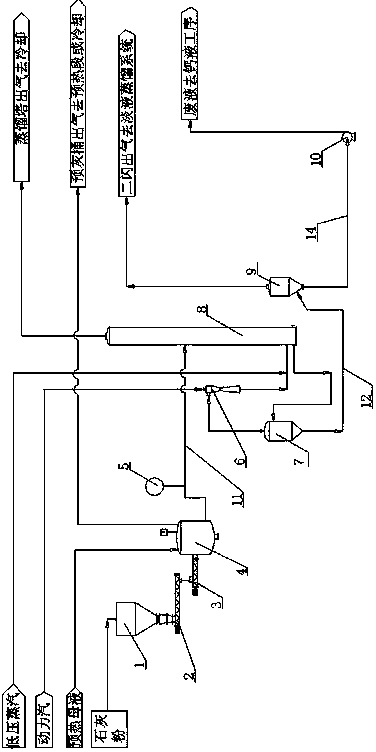

[0030] See attached figure 2 As shown in , the outlet at the bottom of the second flash tank 9 is connected to the second discharge line 14, and the second discharge line 14 is directly connected to the waste liquid feeding pump 15; the pre-ash bucket 4 is directly connected to the distillation tower 8 through the blending line 11; The pre-ash bucket 4 is provided with a preheating mother liquor inlet and a lime powder inlet.

[0031] A pH value analysis device 5 is installed on the blending pipeline 11 . The use of the PH value online analysis device 5 and the speed-regulating ash auger 2 can control the finer lime powder particle size, achieve the purpose of streamlining the process, convenient operation and strong controllability, and has the advantages of safety and energy saving. Reduce staff occupancy.

[0032] A flash tank 7 is connected to the bottom of the distillation tower 8 through a heat pump 6; the distillation tower 8 is provided with a low-pressure steam inl...

Embodiment 2

[0041] The difference with Example 1 is:

[0042] 185 cubic meters of preheated mother liquor enters the pre-ash bucket 4 from the top by spraying, and analyzes the data online according to the PH value online analysis device 5 installed on the blending pipeline. 3. Send 45 tons of lime powder into the pre-ash bucket 4, stir, mix and react in the pre-ash bucket 4, and the ammonia formed by the reaction is sent out from the top of the pre-ash bucket 4, and used for other processes after cooling treatment.

[0043] The reaction liquid in the pre-ash tank 4 flows into the fixed ammonia distillation tower 8, and contacts and exchanges heat with the steam entering from the lower part. When the outlet temperature is 90°C, the ammonia in the liquid phase is evaporated, and the ammonia is output from the top of the distillation tower 8, and is cooled. Afterwards, it is used in other processes, and the calcium hydroxide containing 1.75ti and 90mg / l waste liquid flow out from the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com