NaY compound and preparation method thereof

A compound and reaction mixture technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., to achieve the effects of cheap and easy-to-obtain raw materials, improved heavy oil conversion rate, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This embodiment provides a NaY complex, which is prepared by the following steps:

[0032] Prepare the targeting agent according to the method provided in Example 1 in CN1785808A;

[0033] Put 160g of water glass in a beaker, control the temperature in the beaker to 60℃, add 45g of directing agent, add 27.8g of expanded perlite after stirring evenly, add 4.55g of NaOH and 96.8g of water after thorough mixing, and stir for 1h , Put it into the reactor, crystallize at 100°C for 28 hours, then filter, wash, and dry to obtain the NaY complex, which is recorded as the Z-1 sample.

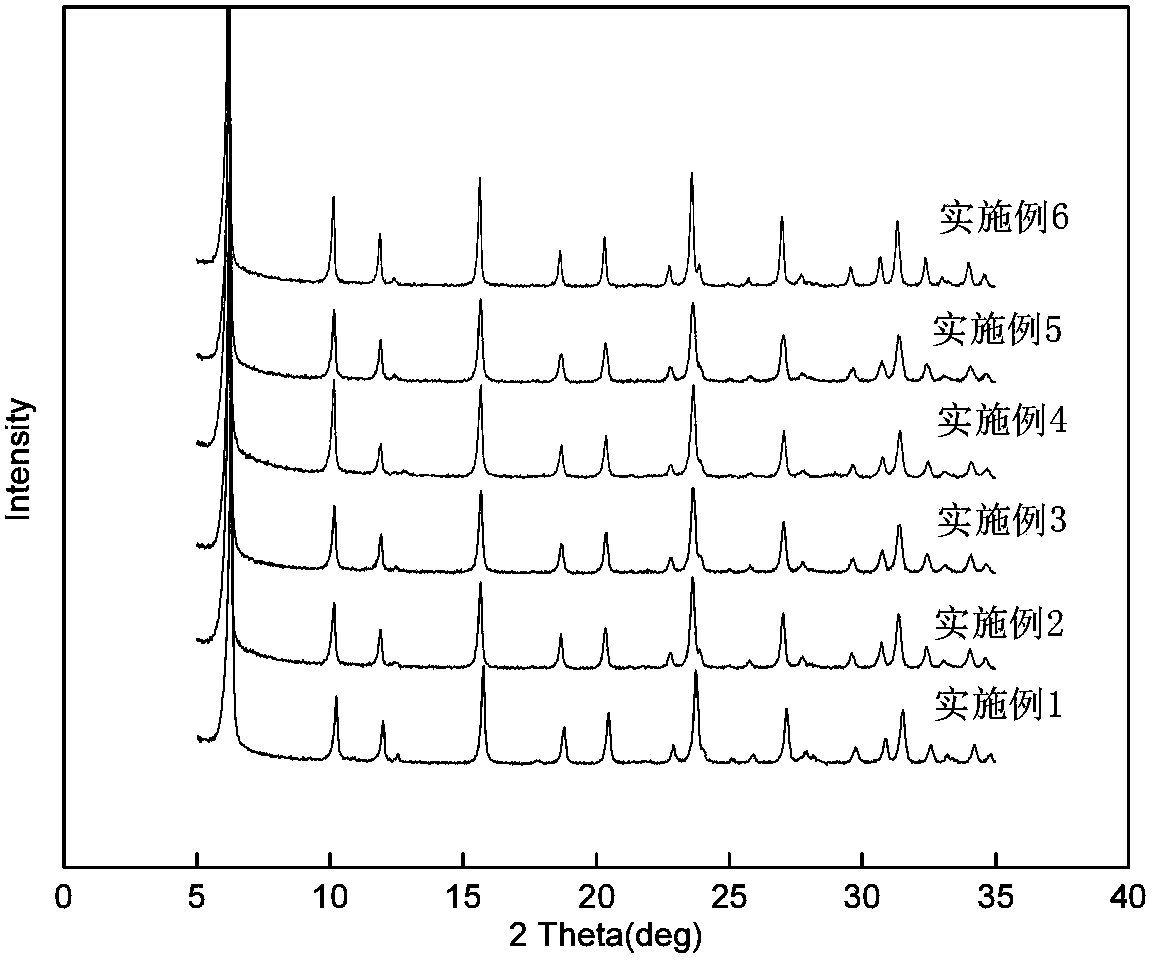

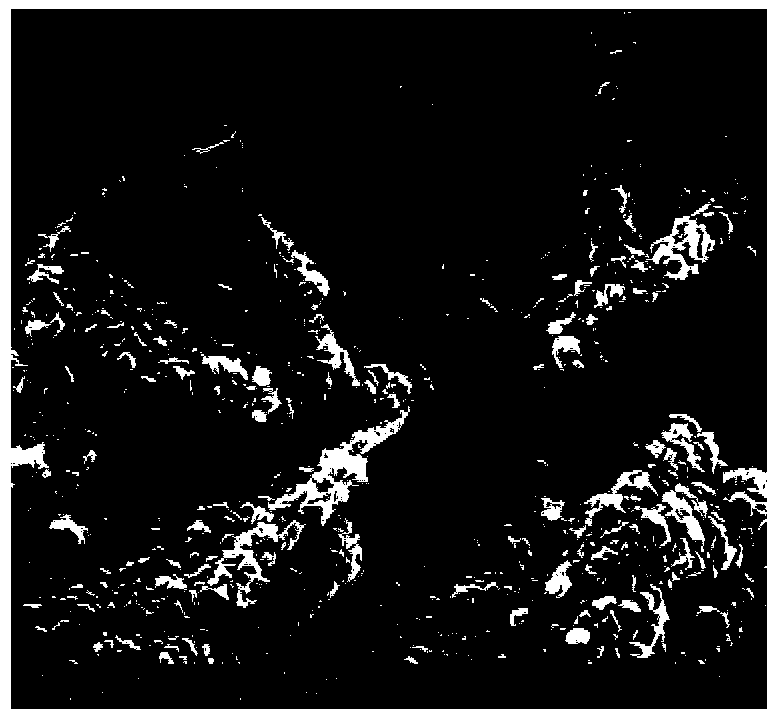

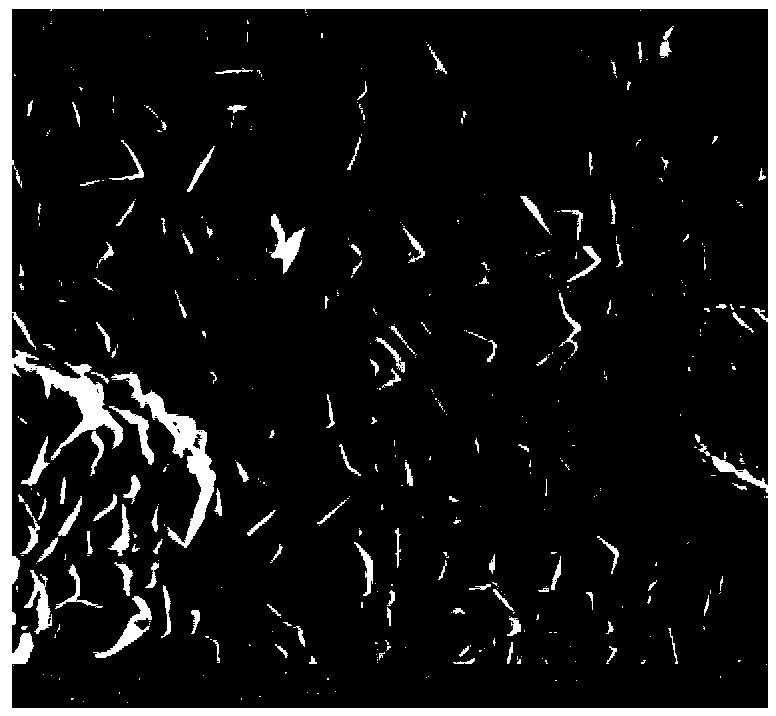

[0034] The bulk density of the NaY composite determined by XRD ray diffraction is 0.2g / cm 3 , The relative crystallinity of the active component is 56%, SiO 2 / Al 2 O 3 The mole ratio is 5.41, and the scanning range 2θ is 5°-35°. The diffraction spectrum is shown in figure 1 , The average grain size is about 200nm (see SEM figure 2 with image 3 ), the BET specific surface area is 669m 2 / g(See Figure ...

Embodiment 2

[0040] This embodiment provides a NaY complex, which is prepared by the following steps:

[0041] Prepare the targeting agent according to the method provided in Example 1 in CN1785808A, the same as in Example 1;

[0042] Place 47g of water glass in a beaker, control the temperature in the beaker to 60℃, add 45g of directing agent, add 27.8g of expanded perlite after stirring well, add 7.32g of NaOH and 79.4g of water after mixing well, and stir for 1h , Put it into the reactor, crystallize at 100°C for 28 hours, then filter, wash, and dry to obtain the NaY complex, which is recorded as the Z-2 sample.

[0043] The bulk density of NaY composite determined by XRD ray diffraction is 0.22g / cm 3 , The relative crystallinity of the active component is 67%, SiO 2 / Al 2 O 3 The molar ratio is 4.2, and the XRD spectrum is similar to Example 1, as figure 1 As shown, the BET specific surface area is 622m 2 / g.

Embodiment 3

[0045] This embodiment provides a NaY complex, which is prepared by the following steps:

[0046] Prepare the targeting agent according to the method provided in Example 1 in CN1785808A, the same as in Example 1;

[0047] Put 89.2g of water glass in a beaker, control the temperature in the beaker to 50℃, add 45g of directing agent, stir well, add 27.8g of expanded perlite, after thoroughly mixing, add 5.3g of NaOH and 85.8g of water, and stir for 1h Afterwards, it was put into the reaction kettle, crystallized at 100°C for 28 hours, then filtered, washed, and dried to obtain the NaY complex, which was recorded as the Z-3 sample.

[0048] The bulk density of the NaY composite determined by XRD ray diffraction is 0.24g / cm 3 , The relative crystallinity of the active component is 65%, SiO 2 / Al 2 O 3 The molar ratio is 4.7, and the XRD spectrum is similar to Example 1, as figure 1 As shown, the BET specific surface area is 670m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com