Rigidity-variable positioning device for bogie axle box of railway vehicle

A bogie shaft and railway vehicle technology, which is applied in the field of variable stiffness positioning devices for railway vehicle bogie axle boxes, can solve the problems of reducing the function of the axle box elastic suspension device, complex structural design, poor assembly versatility, etc., and achieves improved vehicle dynamics. The effect of performance, guaranteeing operation safety, and easy disassembly and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

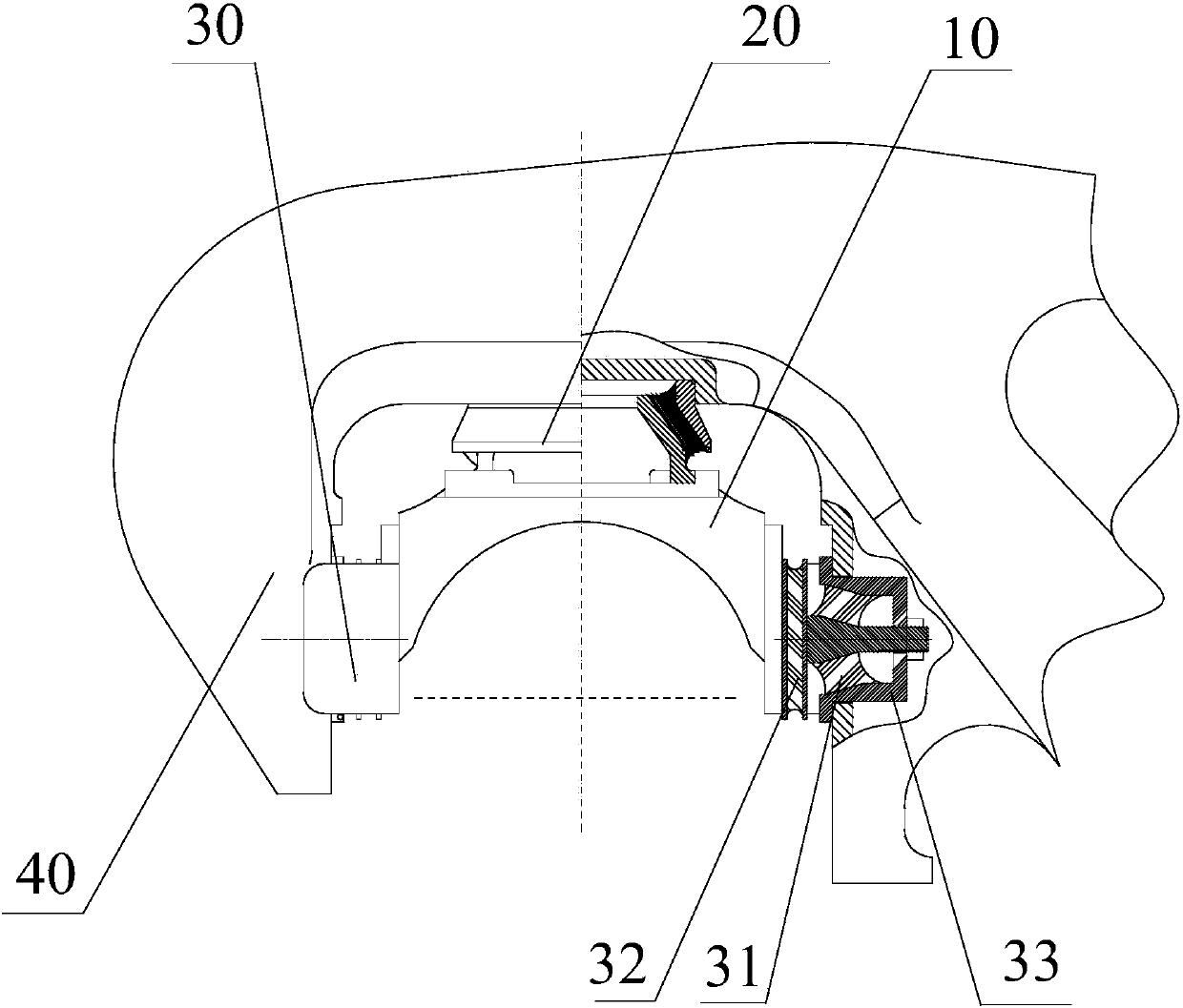

[0045] Such as figure 1 As shown, a kind of railway vehicle bogie axle box variable stiffness positioning device of the present invention mainly consists of a vertical elastic body 20 arranged between the top surface of the axle box bearing saddle 10 and the bottom surface of the side frame pedestal 40, and the The axle box bearing saddle 10 is combined with the longitudinal elastic body 30 between the front and rear sides of the side frame pedestal 40 . The longitudinal elastic body 30 has a small stiffness elastic element 31 and a large stiffness elastic element 32, the small stiffness elastic element 31 is arranged in the elastic body pre-compression device 33, and is connected in series with the large stiffness elastic element 32 under the action of the precompression load F1 layout.

[0046] Such as figure 2 As shown, the large rigidity elastic element 32 has an elastic rubber base layer 32a, and the elastic rubber base layer 32a is sandwiched between two metal bearing...

Embodiment 2

[0056] Such as Figure 7 As shown, another railway vehicle bogie axle box variable stiffness positioning device of the present invention, its overall structure is basically the same as that of Embodiment 1, and the difference is still that it is pre-determined by a small stiffness elastic element 31, a large stiffness elastic element 32 and an elastic body. On the fourth type of longitudinal elastic body 30 composed of compression device 33 .

[0057] Such as Figure 8 As shown, in the fourth longitudinal elastic body 30, its high-rigidity elastic element 32 has an elastic rubber base layer 32a, and the elastic rubber base layer 32a is sandwiched between two metal bearing plates 32b and vulcanized into an integral body with them.

[0058] Its elastic body pre-compression device 33 has a rigid outer cover 33a, and the rigid outer cover 33a is axially provided with a guide positioning screw 33b, and one end of the guide positioning screw 33b stretches out from the opening of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com