Electro-hydraulic proportional valve control pump/motor hydraulic power assisted system of electric automobile

An electro-hydraulic proportional valve and electric vehicle technology, which is applied to the layout of power plant control mechanisms, brakes, vehicle components, etc., can solve the problems of the lack of competitiveness in the use cost of super capacitors, and the industrialization is still a long time away, so as to achieve the manufacturing cost Low cost, simple operation and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

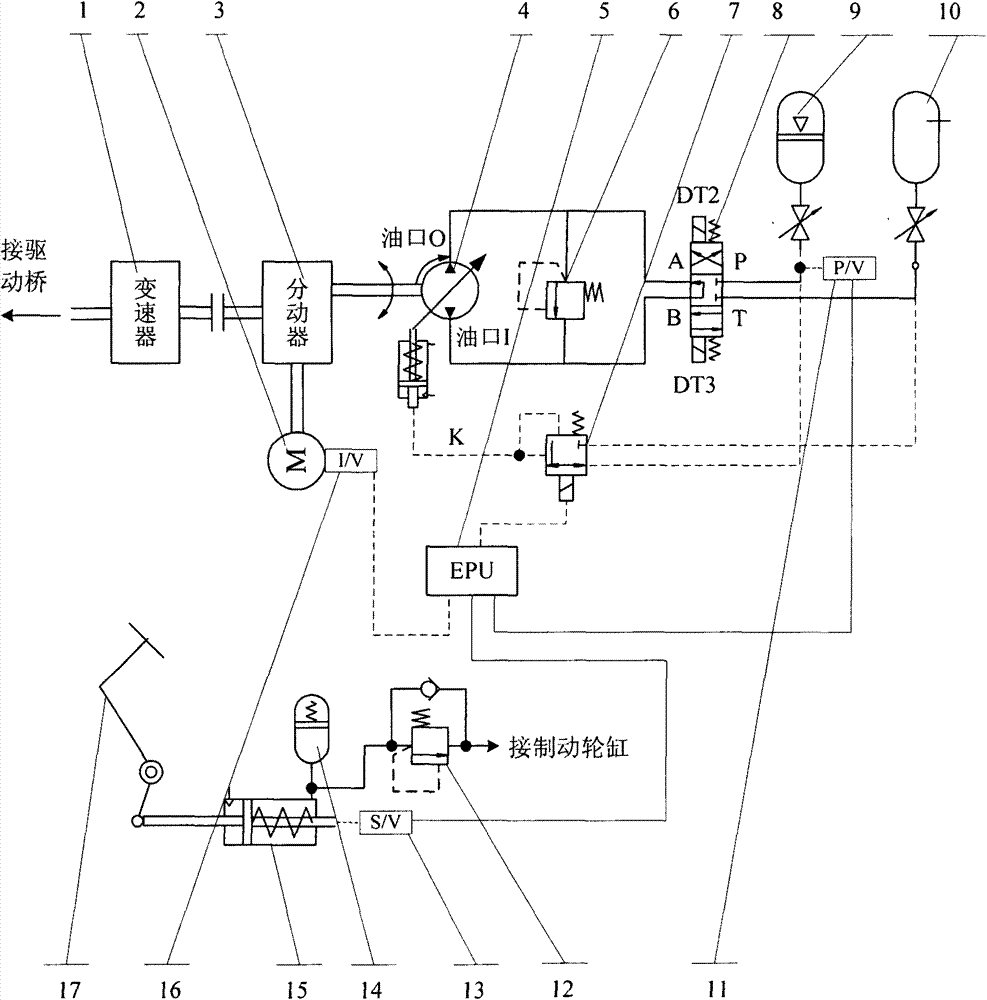

[0020] The electric vehicle hydraulic booster system includes a hydraulic drive circuit, a compound braking system and an electric controller. The hydraulic pump / motor 4 is the mechanical-hydraulic energy conversion element of the hydraulic power assist system, and it is connected with the power motor 2 and the transmission 1 through the transfer case 3 .

[0021] The driving circuit includes a hydraulic pump / motor 4 , a high-pressure accumulator 9 , a low-pressure accumulator 10 , an overflow valve 6 , an electromagnetic reversing valve 8 , a pressure sensor 11 and an electro-hydraulic proportional pressure reducing valve 7 . The oil inlet and outlet ports of the hydraulic pump / motor 4 are respectively connected to the A and B oil ports of the electromagnetic reversing valve 8 through oil pipes, and the P and T oil ports of the electromagnetic reversing valve 8 are respectively connected to the high-pressure accumulator 9 and the low-pressure accumulator 10 connect. The over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com