a welding method

A welding method and welding torch technology, applied in welding equipment, welding equipment, welding accessories, etc., can solve the problems such as the inability to consistently eliminate metal stress and deformation at the weld, the effect is not significant, and the deformation strength of the workpiece, so as to eliminate unevenness. Plastic deformation, ease of automation, effect of improving weld strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

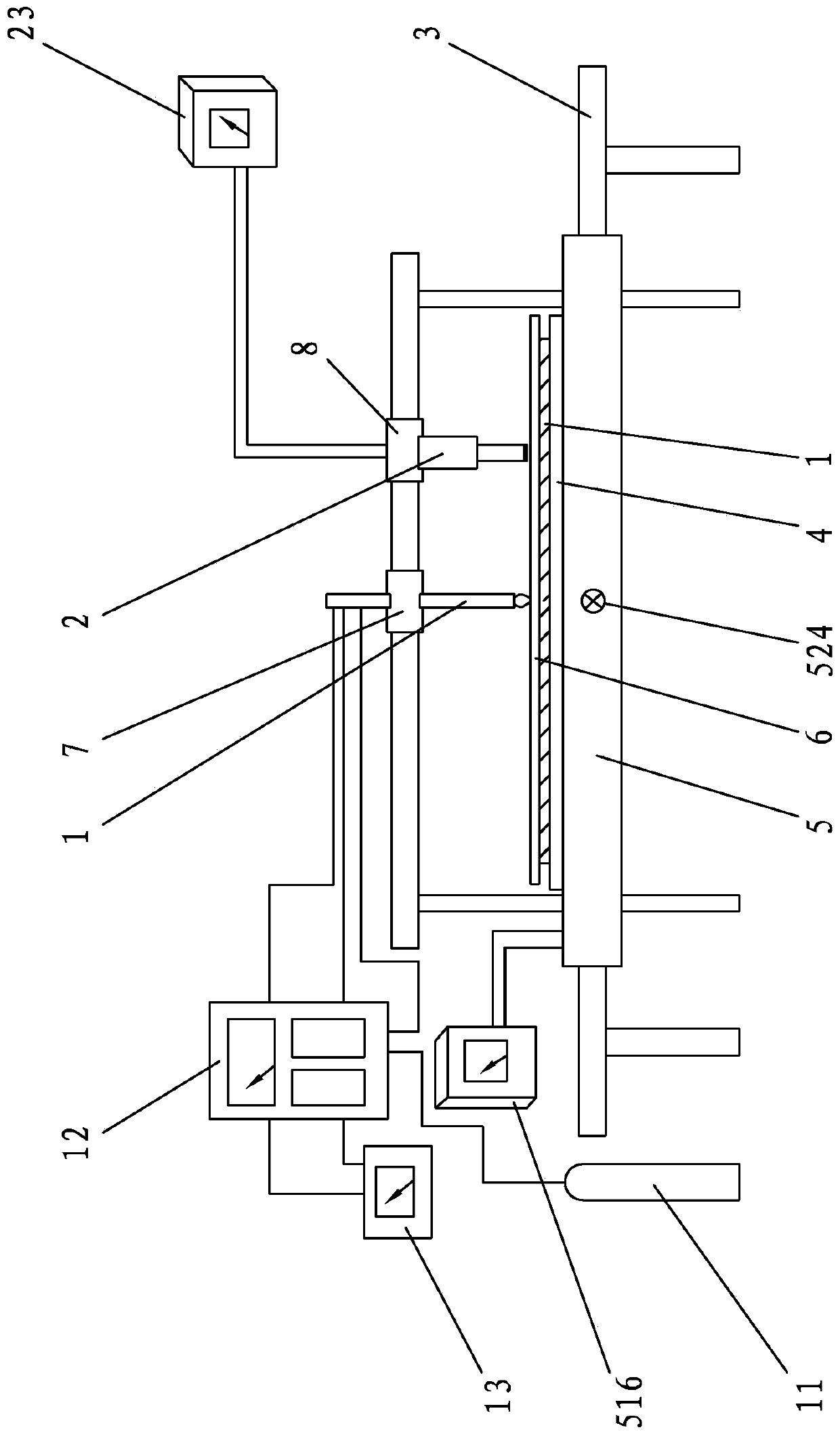

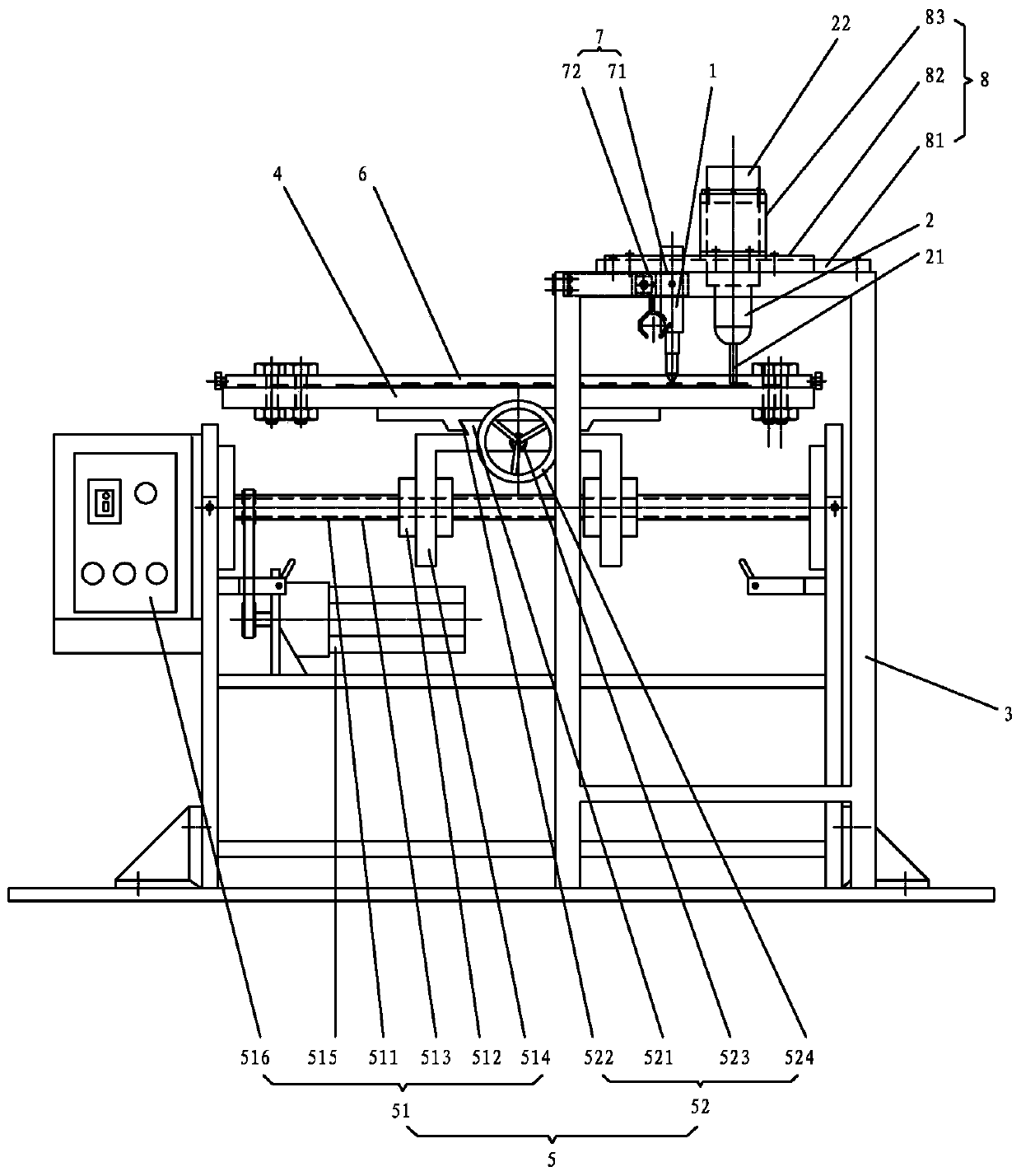

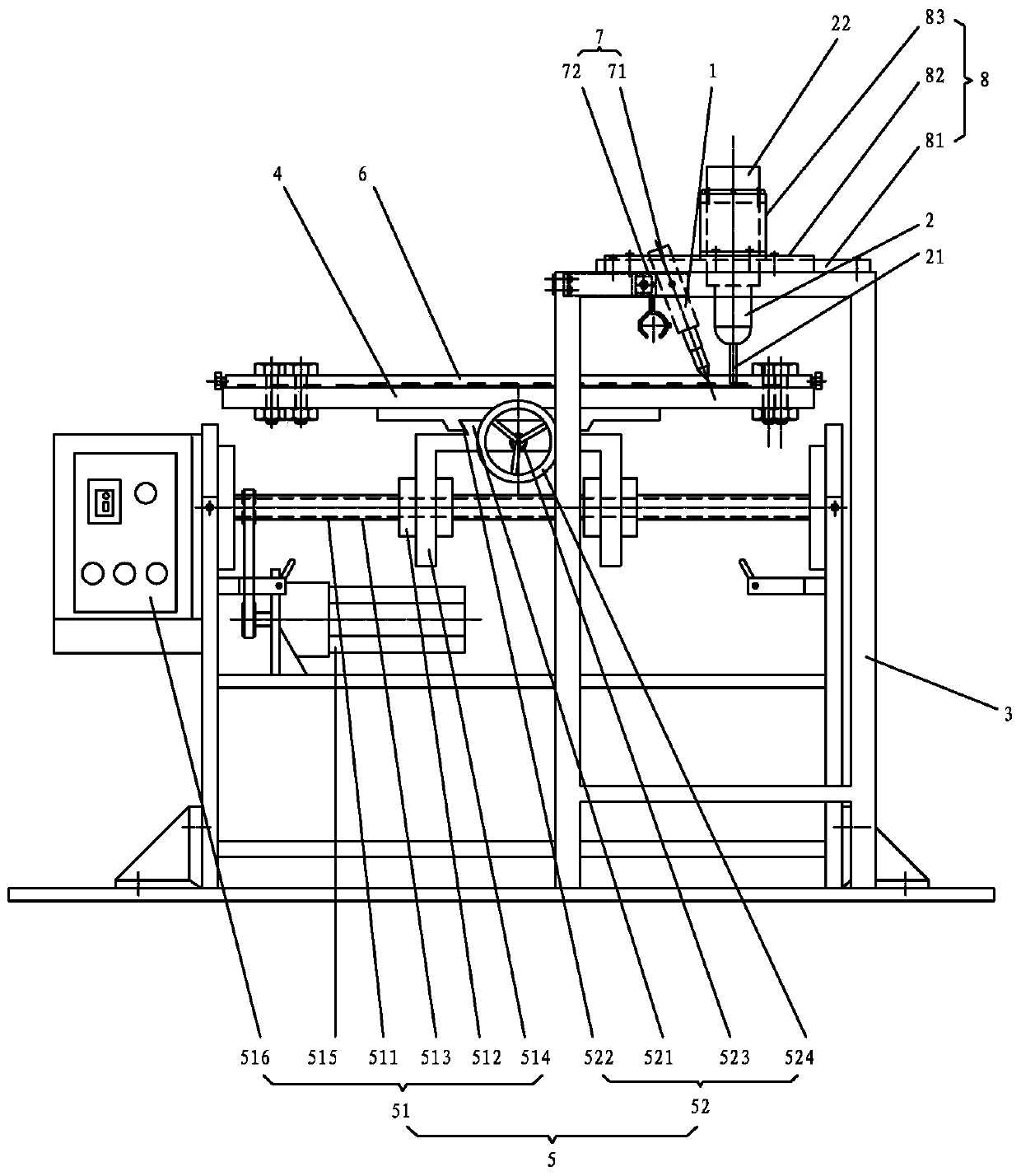

[0054] In a welding method of the present invention, during the whole process of welding the welding torch body to the workpiece, an ultrasonic impact device is used to perform ultrasonic impact on the solidified high-temperature weld metal on the workpiece 9 that has not yet recovered its strength. During the welding process, the high-temperature weld metal solidified at a certain position behind the molten pool along the thickness direction of the welded workpiece 9 is impacted by ultrasonic frequency, and the ultrasonic impact device 2 and the welding torch body 1 are relative to the workpiece 9. Through the ultrasonic excitation force, the weld metal in the state of condensation and contraction is impacted to produce plastic extension to the surrounding, especially the longitudinal diffusion, to compensate for the compressive plas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com