Preparation method of functional gradient performance coil

A functional gradient and performance technology, applied in other manufacturing equipment/tools, engine components, turbines, etc., can solve the temperature gradient field controllability and low repeatability, complex selection of heat treatment regimes, and no compromise heat treatment and transition zone stress. problems, etc., to achieve the effect of high tensile strength and excellent low cycle fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

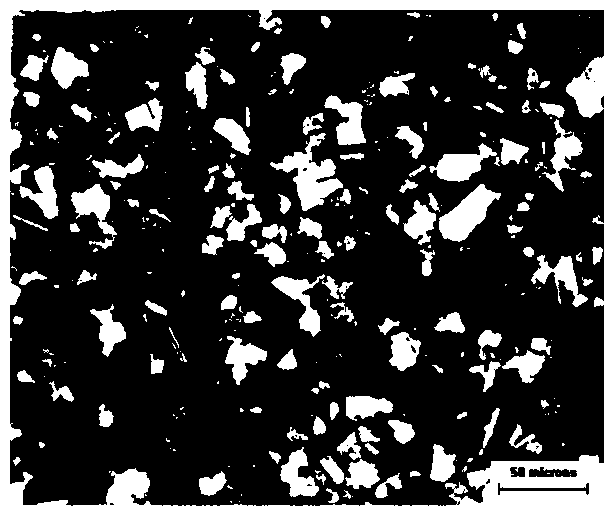

[0019] Using FGH95 alloy, the main chemical composition (mass fraction, %) is: Co8.1, Cr13.1; W3.4, Mo3.4, Al3.4, Ti2.4, Nb3.4, C0.06, Ni balance . The wheel hub, spoke plate and wheel rim of the disc are respectively made of powders with a particle size of less than 50 μm, 50-100 μm, and greater than 100 to less than or equal to 200 μm. Put the powders of the above three particle sizes into carbon steel sheaths for simulation experiments. The size of the sheaths is Φ100×110mm. After the powders are filled, the sheaths are subjected to hot isostatic pressing. The hot isostatic pressing temperature is higher than that of the γ′ phase to completely dissolve. , so that the alloy is completely recrystallized, and equiaxed fine grains are obtained (the hot isostatic pressing temperature is 1200 ° C, the pressure is not less than 100 MPa, and the heat preservation and pressure holding time is not less than 2 hours), the jacket after hot isostatic pressing is peeled off, and the obta...

Embodiment 2

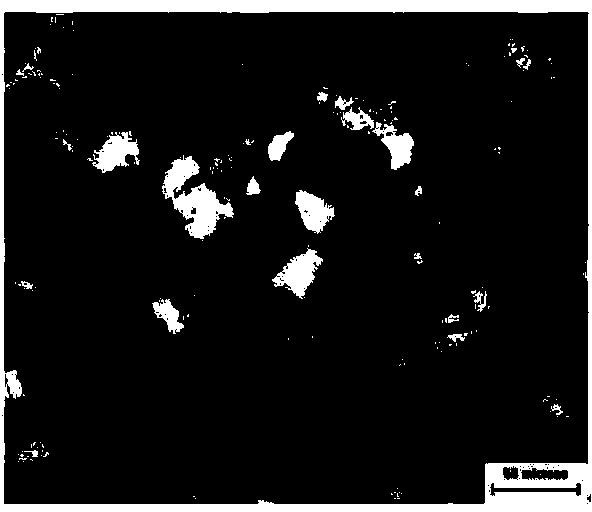

[0021] Using FGH95 alloy, the main chemical composition (mass fraction, %) is: Co8.1, Cr13.1; W3.4, Mo3.4, Al3.4, Ti2.4, Nb3.4, C0.06, Ni balance . The wheel hub, spoke plate and wheel rim of the disc are respectively made of powders with a particle size of less than 50 μm, 50-100 μm, and greater than 100 to less than or equal to 200 μm. Put the powders of the above three particle sizes into carbon steel sheaths for simulation experiments. The size of the sheaths is Φ100×110mm. After the powders are filled, the sheaths are subjected to hot isostatic pressing. The hot isostatic pressing temperature is higher than that of the γ′ phase to completely dissolve. , so that the alloy is completely recrystallized, and equiaxed fine grains are obtained (the hot isostatic pressing temperature is 1170 ° C, the pressure is not less than 100 MPa, and the heat preservation and pressure holding time is not less than 2 hours), and the jacket after hot isostatic pressing is peeled to obtain In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com