A detoxification method for chromium slag dry fixation detoxification

A technology of chromium slag and dry method, which is applied in the field of remediation and disposal of hazardous solid waste containing heavy metals, can solve the problems of chromium slag detoxification treatment process research difficulties, little long-term stability process research and development, and low stable solidification efficiency, and achieve industrialization prospects Optimistic, good heat fixation effect, good stabilization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

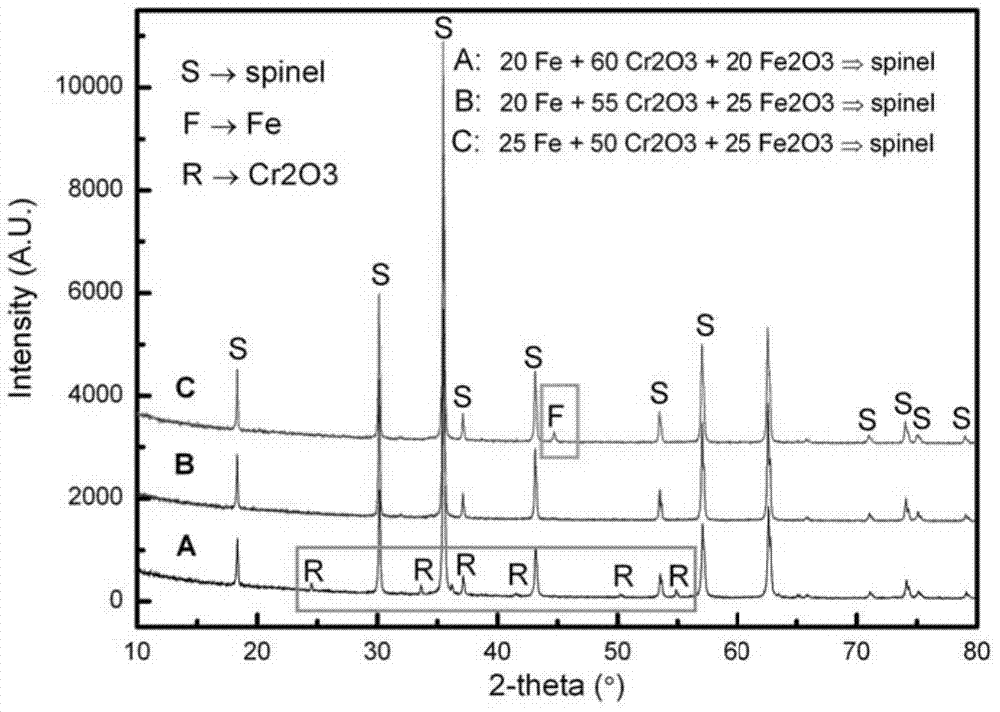

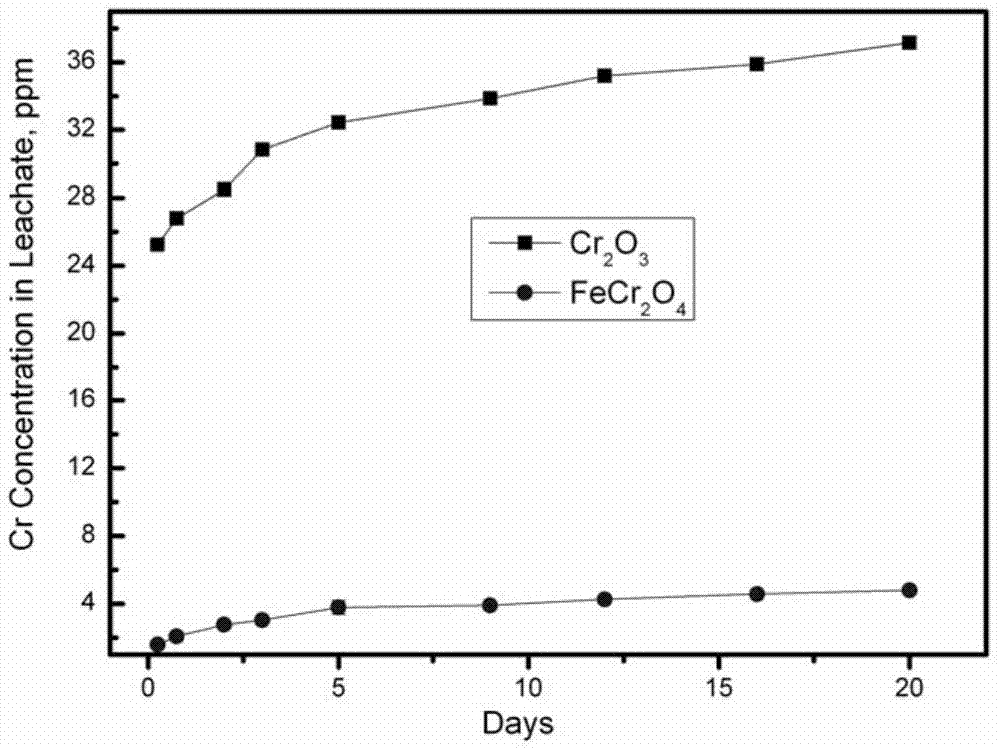

[0027] Example 1: The thermal fixation and detoxification process of iron-based reduction fixative (a mixture of zero-valent iron and ferric oxide) on chromium trioxide and evaluation of its curing effect.

[0028] The process flow of chromium trioxide fixation and detoxification based on iron-based reduction fixative of this embodiment includes the following steps:

[0029] (1) Combining zero-valent iron, Fe 2 O 3 And Cr 2 O 3 Mix in different ratios of 20:20:60, 20:25:55 and 25:25:50 in molar ratios;

[0030] (2) Rotate and mix the samples with different molar ratios in a mixer for 2 hours;

[0031] (3) The fully mixed sample is compressed into a cylindrical compact with a height of 2cm in diameter at a pressure of ≥200Bar in the tablet press;

[0032] (4) Put the compacted cylindrical compacted bodies into a high-temperature furnace for sintering. The cylindrical bodies of each ratio are calcined at 1200°C for 4 hours. After calcining, the solidified and detoxified sintered body of c...

Embodiment 2

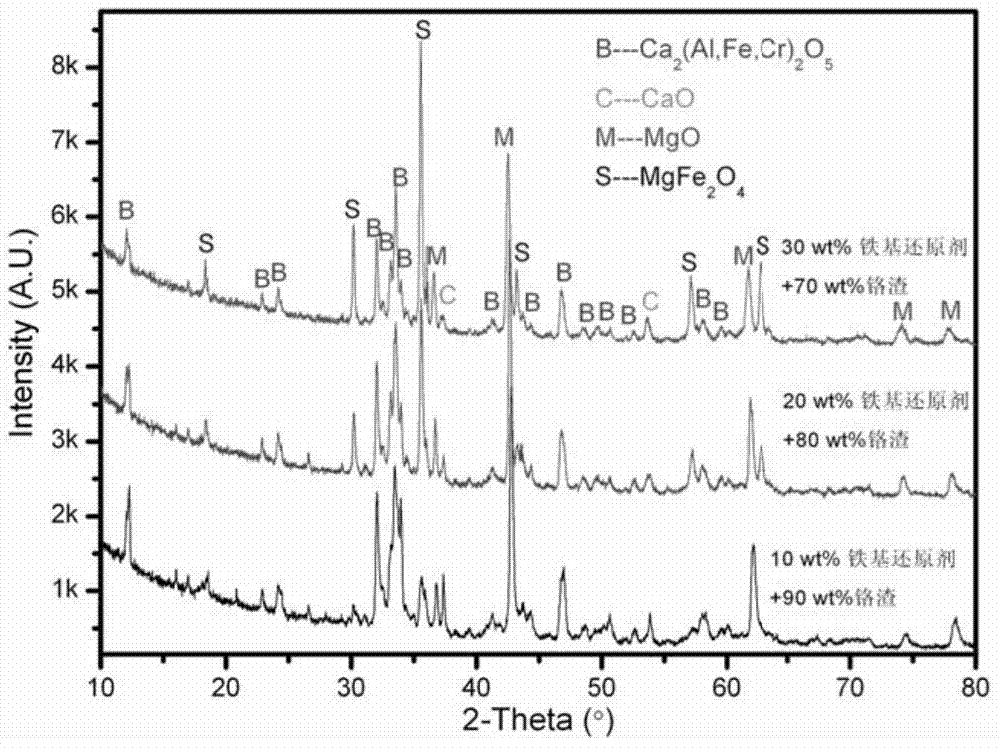

[0035] Example 2: Iron-based reduction fixative (a mixture of zero-valent iron and ferric oxide, the ratio of the amount of the substance is 1:1) to evaluate the thermal fixation and detoxification process of chromium slag and its curing effect.

[0036] In this example, the chromium slag was collected from the chromium slag piled pit in the chromium salt workshop of a chemical plant in South China. The plant had ceased production in the 1980s. The chromium slag was piled in the pit without any treatment and was stored in the chromium slag. The waste rock pit was sealed with 20cm thick cement until now.

[0037] The chromium slag fixation and detoxification process flow based on iron-based reduction fixative of this embodiment includes the following steps:

[0038] (1) After the chromium slag is collected, it is air-dried and ground to a particle size of 1~2mm;

[0039] (2) Mix the iron-based reducing agent and the chromium slag in different ratios of 10:90, 20:80 and 30:70 by mass;

...

Embodiment 3

[0045] Example 3: The thermal fixation and detoxification process of chromium slag with iron-based reduction fixative (ferrous oxalate) and the evaluation of its curing effect.

[0046] In this example, the chromium slag was collected from the chromium slag piled pit in the chromium salt workshop of a chemical plant in South China. The plant had ceased production in the 1980s. The chromium slag was piled in the pit without any treatment and was stored in the chromium slag. The waste rock pit was sealed with 20cm thick cement until now.

[0047] The chromium slag fixation and detoxification process flow based on iron-based reduction fixative of this embodiment includes the following steps:

[0048] (1) After the chromium slag is collected, it is air-dried and ground to a particle size of 1~2mm;

[0049] (2) Mix ferrous oxalate and chromium slag in different mass ratios of 10:90, 20:80, 30:70, 40:60;

[0050] (3) Rotate and mix samples with different mass ratios in a mixer for 2 hours;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com