A kind of immobilized visible light responsive photocatalyst and preparation method thereof

A photocatalyst and visible light technology, applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. Restricting practical application and other issues, to achieve the effect of expanding the application field and scope, low cost of use, and firm adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

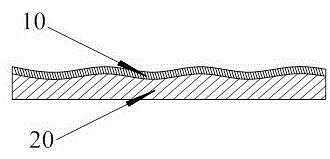

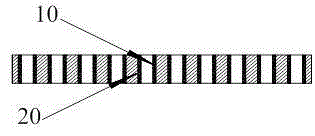

Image

Examples

Embodiment 1

[0042] Photocatalytic material: 30 grams

[0043] Cerium-zirconium material (calculated as cerium-zirconium solid solution): 20 grams

[0044] Mixed lanthanum praseodymium: 10 grams

[0045] Poly aluminum: 25 grams

[0046] Silicon magnesium oxide (calculated as magnesium silicate): 15 grams

[0047] Water: 40 grams

[0048] Step A: Weigh the above-mentioned materials, mix them uniformly, and then disperse them in a grinder for 12 hours. Take out the ground liquid and adjust its pH to 6.5 to obtain a colloidal slurry;

[0049] Step B: Choose a ceramic or metal material of suitable shape and size as the carrier, and clean the oil, dirt, impurities, etc. on the surface;

[0050] Step C: According to the shape and structure of the carrier, apply the colloidal slurry to the carrier by dipping, spraying, brushing and other methods, and remove the excess liquid adhering to the carrier to form a layer on the skeleton carrier Uniform and continuous coating film with a thickness of 0.1 to 1.2mm;

...

Embodiment 2

[0053] Photocatalytic material: 55 grams

[0054] Cerium-zirconium material (calculated as cerium-zirconium solid solution): 15 grams

[0055] Mixed lanthanum praseodymium: 5 grams

[0056] Poly aluminum: 15 grams

[0057] Silicon magnesium oxide (calculated as magnesium silicate): 10 grams

[0058] Water: 60 grams

[0059] Step A: Weigh the above-mentioned materials, mix them uniformly, and then disperse them in a grinder for 20 hours. Take out the ground liquid and adjust its pH to 8.5 to obtain a colloidal slurry;

[0060] Step B: Choose a ceramic or metal material of suitable shape and size as the carrier, and clean the oil, dirt, impurities, etc. on the surface;

[0061] Step C: According to the shape and structure of the carrier, apply the colloidal slurry to the carrier by dipping, spraying, brushing and other methods, and remove the excess liquid adhering to the carrier to form a layer on the skeleton carrier Uniform and continuous coating film with a thickness of 0.1 to 1.2mm;

[...

Embodiment 3

[0064] Photocatalytic material: 40 grams

[0065] Cerium-zirconium material (calculated as cerium-zirconium solid solution): 18 grams

[0066] Mixed lanthanum praseodymium: 8 grams

[0067] Poly aluminum: 20 grams

[0068] Silicon magnesium oxide (calculated as magnesium silicate): 14 grams

[0069] Water: 50 grams

[0070] Step A: Weigh the above-mentioned materials, mix them uniformly, and then disperse them in a grinder for 16 hours. Take out the ground liquid and adjust its pH to 7 to obtain a colloidal slurry;

[0071] Step B: Choose a ceramic or metal material of suitable shape and size as the carrier, and clean the oil, dirt, impurities, etc. on the surface;

[0072] Step C: According to the shape and structure of the carrier, apply the colloidal slurry to the carrier by dipping, spraying, brushing and other methods, and remove the excess liquid adhering to the carrier to form a layer on the skeleton carrier Uniform and continuous coating film with a thickness of 0.1 to 1.2mm;

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com