Functionalized ionic liquid hybrid mesoporous molecular sieve MCM-48 composite material and preparation method and application thereof

A technology of MCM-48 and mesoporous molecular sieve, which is applied in the field of functionalized ionic liquid hybrid mesoporous molecular sieve MCM-48 composite material and its preparation, can solve the problems of a large amount of waste residue, waste liquid, secondary pollution, and high investment cost. Achieve controllable adsorption and desorption, convenient cubic structure, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

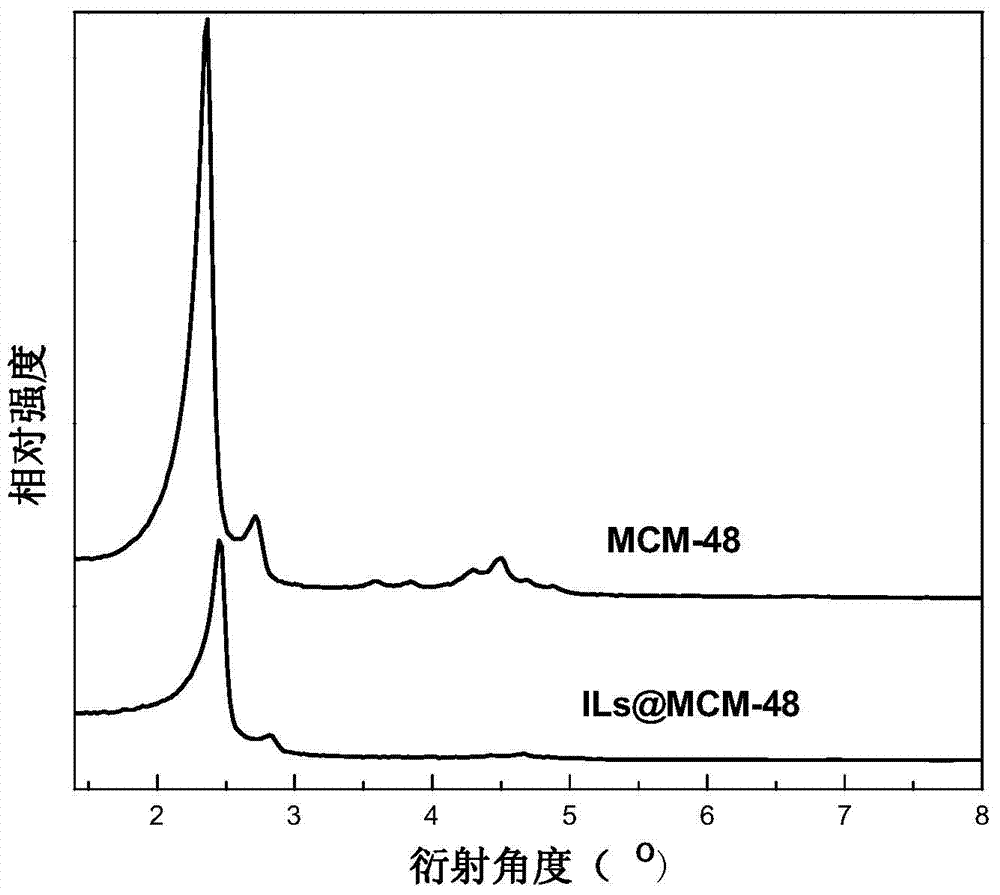

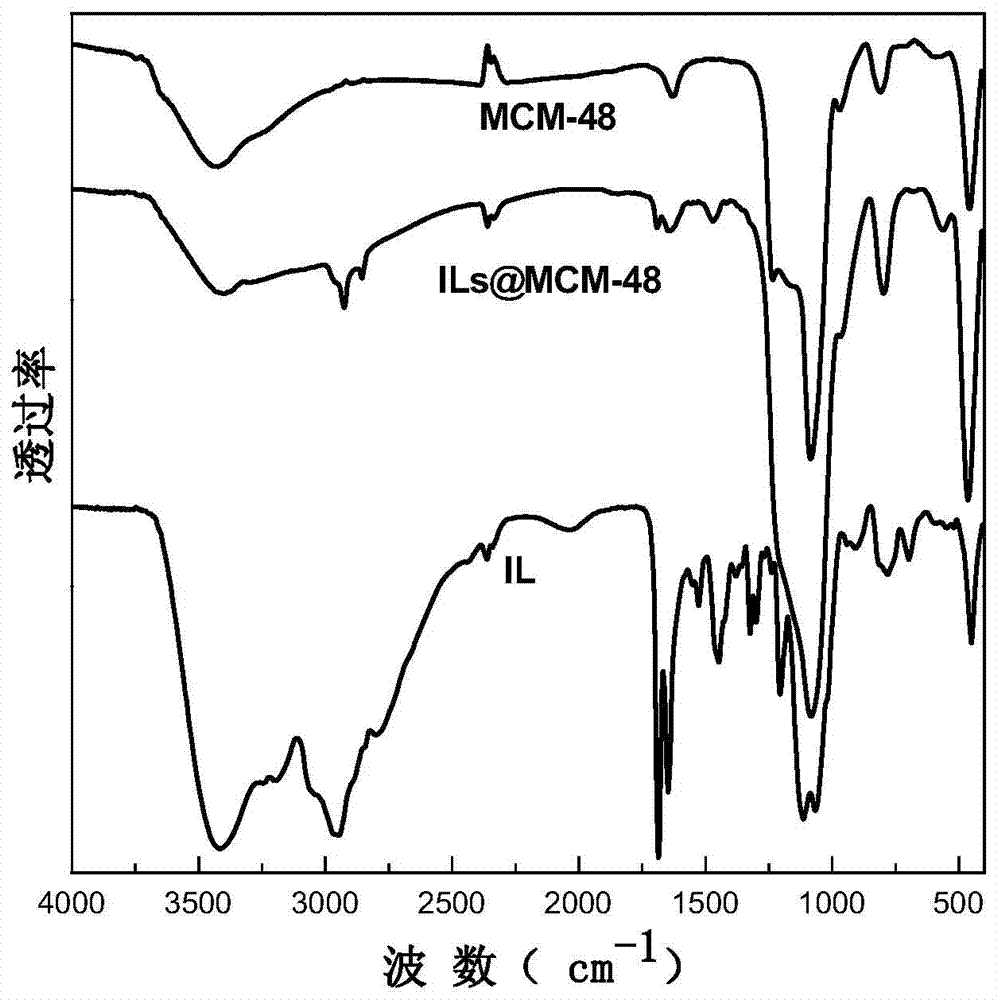

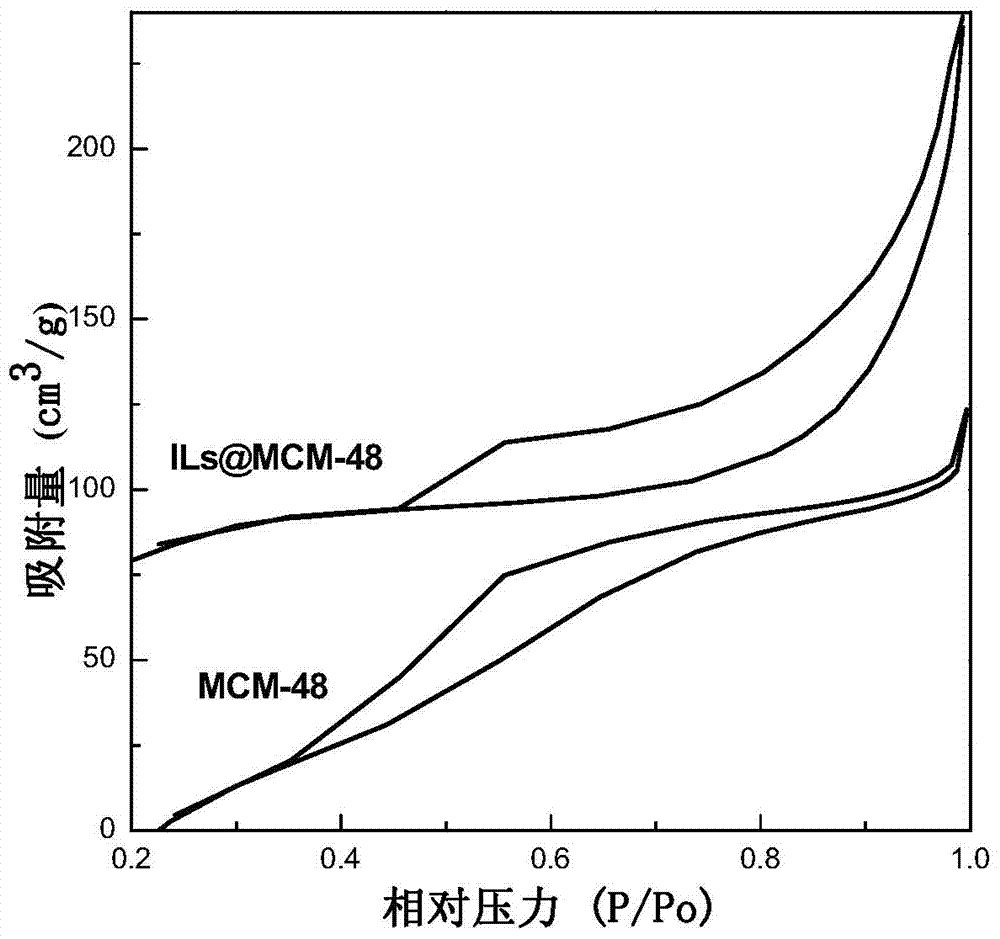

[0042] A preparation method of functionalized ionic liquid hybrid molecular sieve MCM-48 composite material, the steps are as follows:

[0043] (1) Equimolar amounts of N-[3-(triethoxysilyl)propyl]-4,5-dihydroimidazole (0.01mol, 2.74g) and 3-bromopropylamine hydrobromide (0.01mol , 2.19g) was added into 10mL ethanol, stirred and refluxed at 80°C for 24 hours. Ethanol was removed by rotary evaporation at 80°C, the remaining product was washed with pentane to remove unreacted precursors, and vacuum-dried at room temperature to obtain a functionalized ionic liquid. The synthesis process of functionalized ionic liquid is as follows:

[0044]

[0045] (2) Dissolve 2.6g of CTAB in a mixture consisting of 50ml of ethanol, 12ml of ammonia water, and 120ml of distilled water, and stir at room temperature until the solid is completely dissolved and the bubbles on the liquid surface basically disappear. According to the molar ratio of 1:9, 0.8g of functionalized ionic liquid was dis...

Embodiment 2

[0057] A preparation method of functionalized ionic liquid hybrid molecular sieve MCM-48 composite material, the steps are as follows:

[0058] (1) Add equimolar amounts of N-(3-butyltriethoxysilane)-imidazole (0.01mol, 2.44g) and 2-iodoethylamine hydroiodide (0.01mol, 2.99g) into 10mL In ethanol, stir and reflux at 70°C for 48 hours. Ethanol was removed by rotary evaporation at 80°C, the remaining product was washed with pentane to remove unreacted precursors, and vacuum-dried at room temperature to obtain a functionalized ionic liquid. The synthesis process of functionalized ionic liquid is as follows:

[0059]

[0060] (2) Dissolve 2.6g of CTAB in a mixture consisting of 50ml of ethanol, 12ml of ammonia water, and 120ml of distilled water, and stir at room temperature until the solid is completely dissolved and the bubbles on the liquid surface basically disappear. According to the molar ratio of 1:19, 0.44g of functionalized ionic liquid was dissolved in 5mL of methan...

Embodiment 3

[0067] A preparation method of functionalized ionic liquid hybrid molecular sieve MCM-48 composite material, the steps are as follows:

[0068] (1) Add equimolar amounts of 2-(2-pyridyl)ethyltrimethoxysilyl (0.01mol, 2.27g) and 2-chloroethylamine hydrochloride (0.01mol, 1.16g) to 10mL of ethanol , stirred and refluxed at 90°C for 20 hours. Ethanol was removed by rotary evaporation at 80°C, the remaining product was washed with pentane to remove unreacted precursors, and vacuum-dried at room temperature to obtain a functionalized ionic liquid. The synthesis process of functionalized ionic liquid is as follows:

[0069]

[0070] (2) Dissolve 2.6g of CTAB in a mixture consisting of 50ml of ethanol, 12ml of ammonia water, and 120ml of distilled water, and stir at room temperature until the solid is completely dissolved and the bubbles on the liquid surface basically disappear. According to the molar ratio of 3:17, 0.84g of functionalized ionic liquid was dissolved in 5mL of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com