expandable skirt aortic mechanical valve

A mechanical valve and aorta technology, applied in the field of medical devices, can solve the problems of high incidence of malignant arrhythmia, adverse cardiac function recovery, complex technical process, etc. Easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to enable those skilled in the art to better understand the present invention, the present invention will be further clearly and completely described below in conjunction with the accompanying drawings.

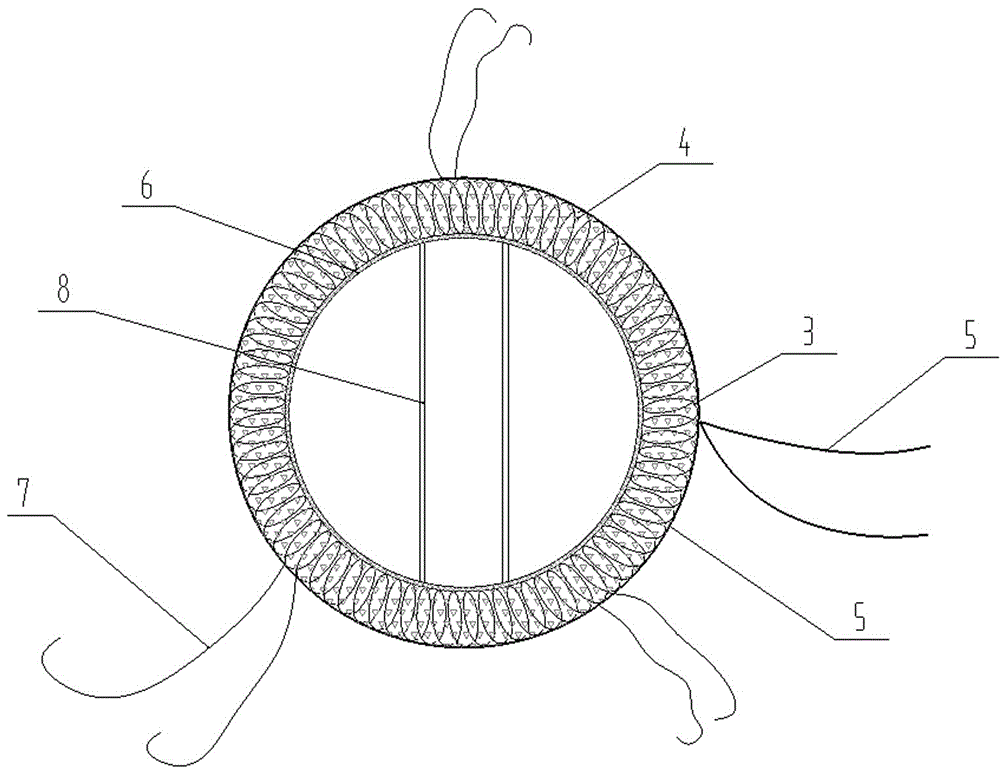

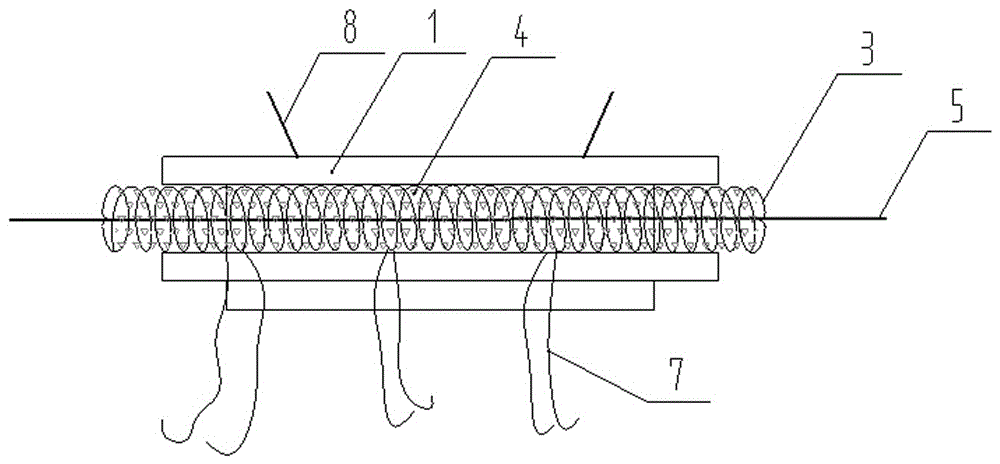

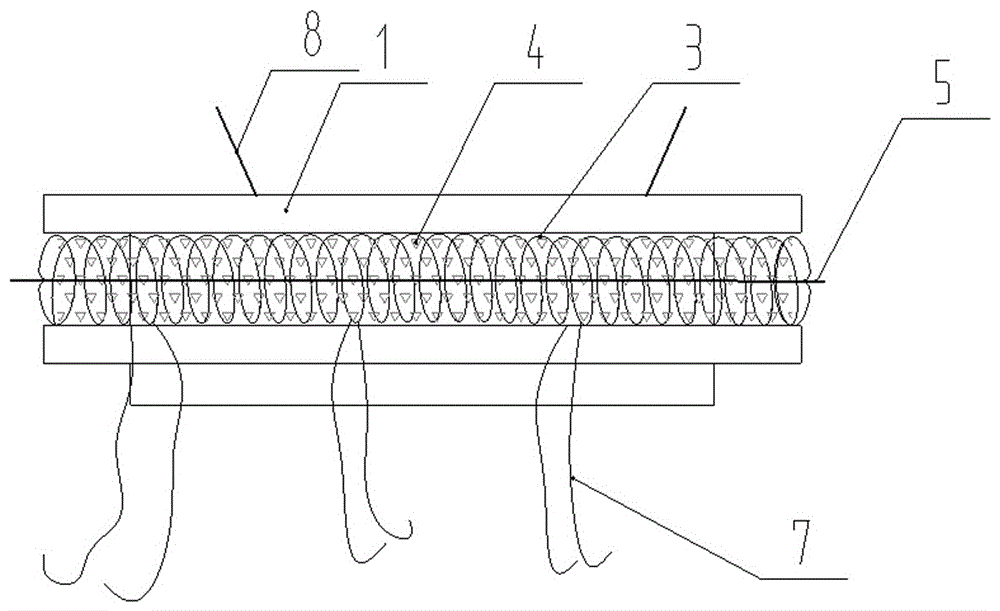

[0025] A kind of expanded valve skirt aortic mechanical valve according to the present invention, such as figure 1 , figure 2 and image 3 As shown, including valve frame 1, leaflet 8,, the outer circle side of valve frame 1 forms annular valve groove 2 ( Figure 6 ), an annular spring valve skirt 3 is fixed in the annular valve groove 2 ( Figure 4 ), the open cavity formed inside the spring flap skirt 3 is filled with a polyester fiber filling body 4, and the outer waist of the spring flap skirt 3 is bound with a forming thread 5.

[0026] The "spring" of the spring flap skirt 3 is made of nickel-titanium alloy wire material. When making, the nickel-titanium metal wire is wound around the designed model to form a spring shape. Polyester fiber filler 4 s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com