Method for manufacturing square-round core aluminum-plastic membrane lithium ion battery for evaluating

A lithium ion battery and a manufacturing method technology are applied in the manufacturing field of square-round core aluminum-plastic film lithium ion batteries for evaluation, which can solve problems such as poor data consistency, electrolyte leakage, battery bulging, etc., and achieve uniform current density distribution, High reliability and good consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

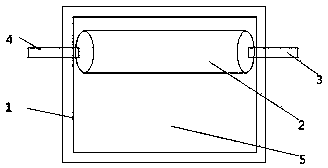

Image

Examples

Embodiment 1

[0022] Positive sheet production: LiFePO 4 , KS, SP, and PVDF are made into a slurry with a solid content of 50% in a ratio of 90:2:2:6, and the surface density is 300g / m2 on a coating machine 2 After drying the pole piece at 110°C for 15 hours, take out the pole piece cut into 50×700mm, and roll it on the roller machine to form a compacted density of 2.20 g / m 3 The pole piece is ultrasonically welded on one end of the pole piece with an aluminum lug.

[0023] Negative sheet production: FSN, SP, CMC, and SBR are made into a slurry with a solid content of 40% in a ratio of 95:1:2:2, and the surface density is 150g / m on a coating machine 2 After drying the pole piece at 110°C for 15 hours, take out the pole piece cut into 57×800mm, and roll it on the roller machine to form a compacted density of 1.60g / m 3 The pole piece is spot-welded with a nickel lug at one end of the pole piece.

[0024] Place the PE separator (25μm thick, 60mm wide), negative electrode, separator, and pos...

Embodiment 2

[0027] The preparation method of the positive electrode sheet is the same as in Example 1, and the compacted density is 2.10 g / m 3 , Pole size 50 × 500mm.

[0028] The manufacturing method of the negative electrode sheet is the same as in Example 1, and the size of the electrode sheet is 57×550mm.

[0029] The winding is the same as in Example 1, and the battery-grade aluminum-plastic composite film is cut into a size of 10×16cm, packaged and dried according to the same method as in Example 1, and then moved into an environment with a relative humidity of ≤2%, and inject 1mol through the liquid injection port / L LiBOB in the EC:DMC:EMC:PC mass ratio of 3:1:1:1 electrolyte 10ml immerse the winding core, seal it, and get a 10×8cm square-round core aluminum-plastic film battery.

Embodiment 3

[0031] The preparation method of the positive electrode sheet is the same as in Example 1, and the compacted density is 2.40 g / m 3 , Pole size 50 × 500mm.

[0032] The manufacturing method of the negative electrode sheet is the same as in Example 1, and the size of the electrode sheet is 57×550mm.

[0033] Place the diaphragm, negative electrode sheet, 25μm PP, PE composite diaphragm, and positive electrode sheet in order from bottom to top. Φ A 4mm needle is wound into a core, then wrapped and fixed with adhesive tape, a 11×22cm aluminum-plastic composite film is cut, packaged and dried as in Example 1, then moved into an environment with a relative humidity of ≤2%, and injected through the liquid injection port 1mol / L LiBF 4 In the AN:DEC:EMC:GBL mass ratio of 5:1:1:1 electrolyte 10ml submerged core, sealed, to get a 11 × 11cm square - round core aluminum-plastic film battery.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com