Tensile cable and method for manufacturing same

A tensile and cable technology, used in cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of easy breaking, low flexibility of metal materials, poor tensile strength of cables, etc. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

[0030] Cables in the prior art generally include: an insulating outer layer and a conductor inner core. The conductor inner core is the main carrier for power transmission of the cable and is usually made of metal materials such as copper and aluminum. Due to the low flexibility of the metal material, it is easy to break when subjected to a large tensile force. Therefore, in some special applications, for example, when the cable needs to be pulled, the cable with a conductor inner core made of a metal material cannot meet the requirements.

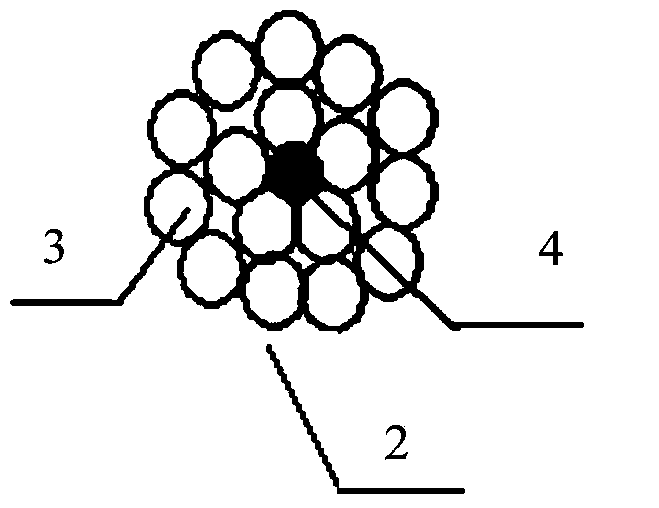

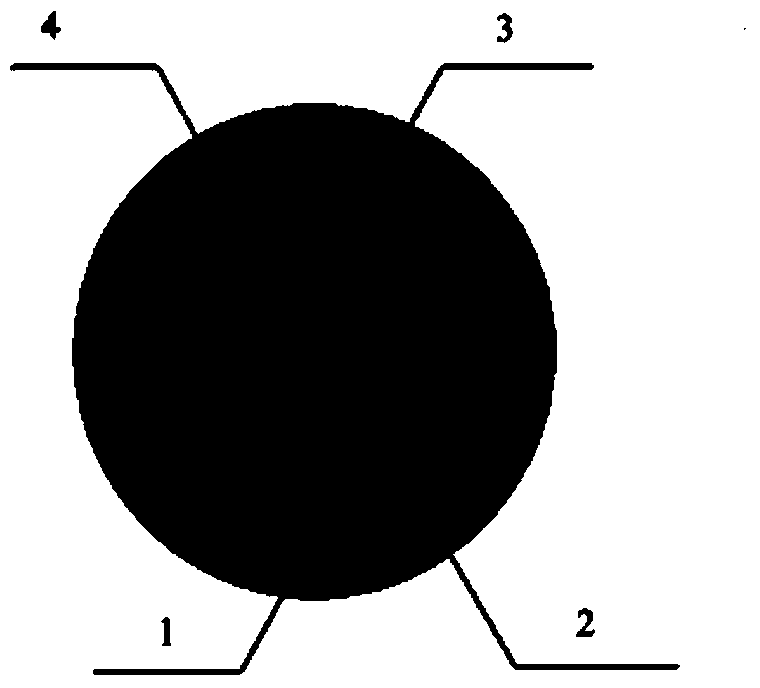

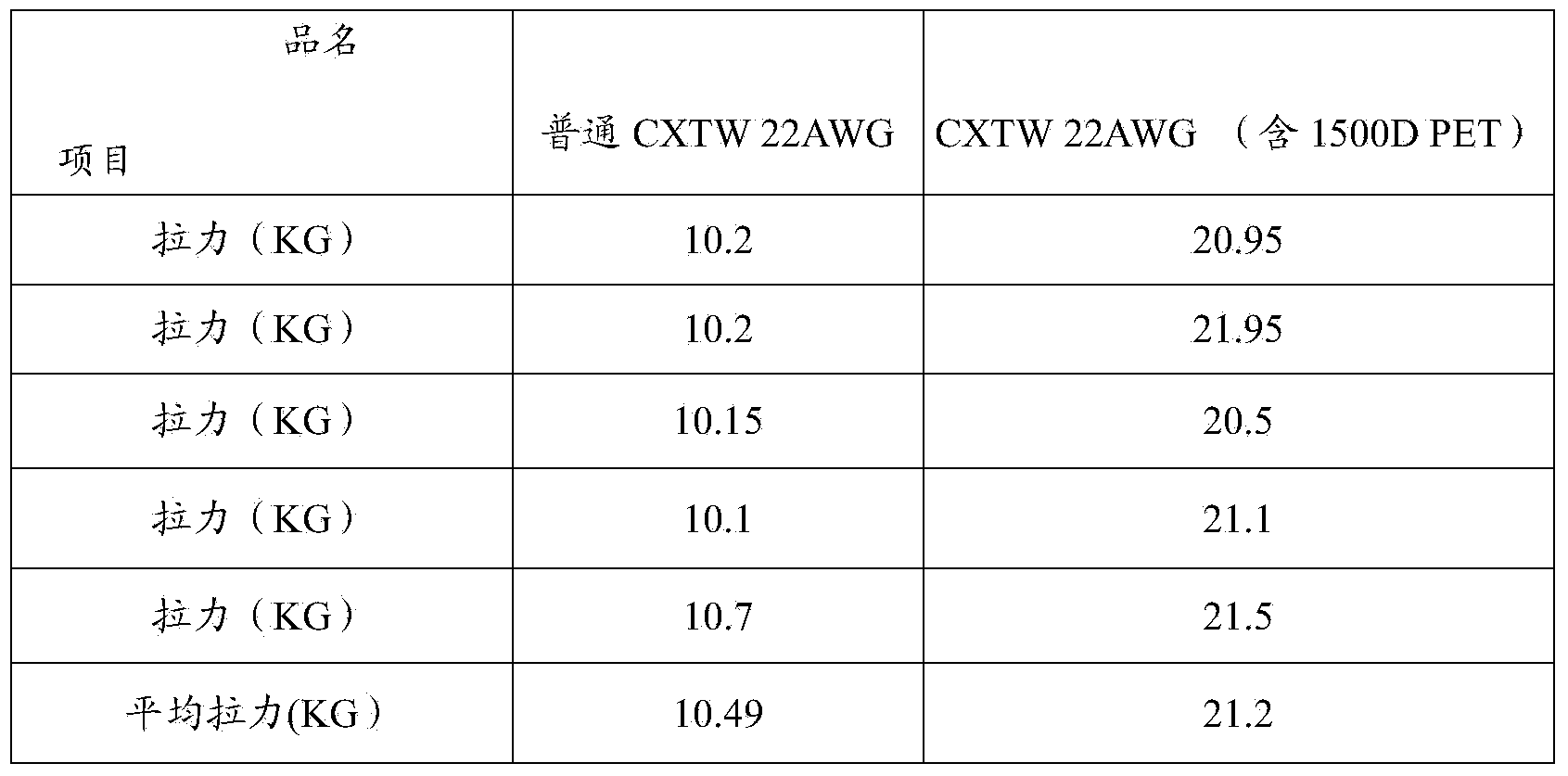

[0031] Therefore, an embodiment of the present invention provides a tensile cable, which uses a twisted metal wire and a PET wire to make a conductor inner core, which effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com