A split-type manufacturing method of a micro-imprinting mold

A manufacturing method and micro-embossing technology, which is applied to the photoplate-making process, instruments, optics, etc. of the pattern surface, and can solve the problems of destroying the mold pattern, difficulty in demoulding, poor repeatability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

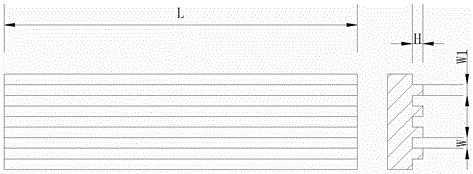

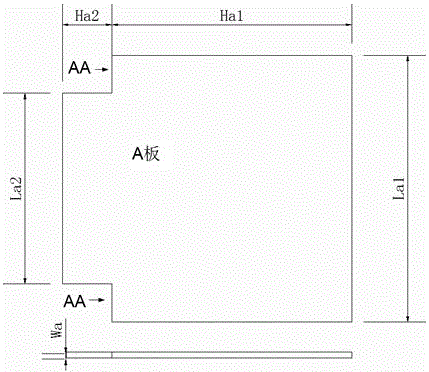

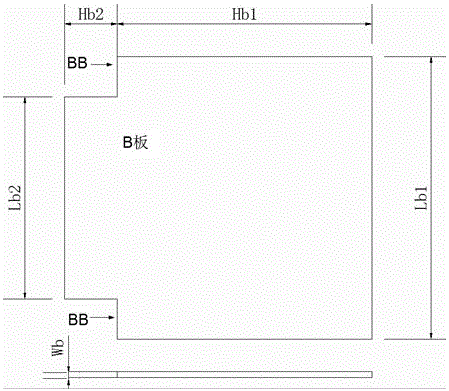

[0063] (1) According to figure 1 In the imprinted micro-groove pattern shown, the groove width W is 0.01 mm, the height H is 0.5 mm, the length L is 190 mm, and the interval W1 is 0.01 mm. Design the processing modules required to manufacture molds. The processing module consists of a board (eg figure 2 shown) Board B (as image 3 As shown), the number of A boards is 250, and the number of B boards is 250. Among them, A board and B board are composed of upper and lower parts respectively. The cuboid structure in the lower part of plate A and B has the same length, width and height, and the cuboid structure in the upper part has the same length and width; the lower part of A plate Ha1, La1 and Wa are 290mm, 200mm and 0.01mm respectively, and the lower part of B plate is Hb1 , Lb1 and Wb are 290mm, 200mm and 0.01mm respectively; part Ha2 on board A is 10mm, La2 is 190mm, Wa is 0.01mm, part Hb2 on board B is 9.5mm, Lb2 is 190mm, and Wb is 0.01mm.

[0064] (2) Machining the m...

Embodiment 2

[0067] A split-type manufacturing method of a micro-imprinting mold, the method comprising the following steps:

[0068] (1) According to Figure 5 The imprinted micro-groove pattern shown has a groove width of 0.3 mm, a depth of 0.5 mm, and a spacing of 0.3 mm. The length of the groove is 100mm, and the processing module of the required manufacturing mold is designed. The processing module consists of a board (eg Image 6 shown) Board B (as Figure 7 As shown), the number of A boards is 6, and the number of B boards is 7. The A board and B board are composed of upper, middle and lower parts respectively. The upper and lower parts are cuboid structures with equal width and different length and height, and the middle part is trapezoidal The upper bottom of the trapezoid is equal in length to the part of the cuboid structure on the board, the length of the lower bottom is equal to the part of the cuboid structure under the board, and the upper, middle and lower parts are inte...

Embodiment 3

[0072] A split-type manufacturing method of a micro-imprinting mold, the method comprising the following steps:

[0073] (1) According to Figure 9 For the embossed micro-rectangular pattern shown, the rectangle protrudes 0.3 mm high and 0.5 mm wide and long. The interval between the rectangles is 0.5mm, and the processing module of the required manufacturing mold is designed. The processing module consists of a rod (eg Figure 10 shown) B stick (as Figure 11 shown) C stick (as Figure 12 As shown), wherein rod A and rod B are cuboid structures with a square base, rod C is a cuboid structure, and the sides of the cuboid structure of rod A, rod B and rod C are equal in length but unequal in height; the cuboid structure of rod A is The length, width and height are 0.5mm, 0.5mm and 10.3mm respectively, the length, width and height of the B-bar cuboid structure are 0.5mm, 0.5mm and 10mm respectively, and the length, width and height of the C-bar cuboid structure are 0.5mm , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com