Counter-pull type polishing brush

A grinding brush, reverse-pull technology, used in portable grinding machines, grinding heads, grinding machines, etc., can solve the problem that parts cannot be ground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

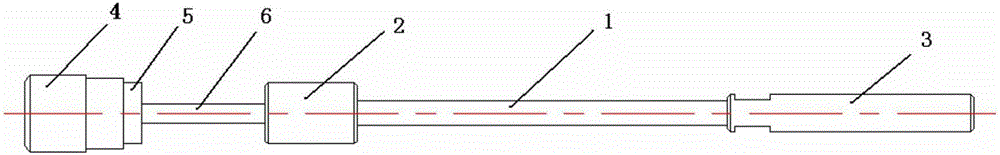

[0013] See attached figure 1 As shown, this kind of anti-pull type grinding brush is composed of a pull rod and a grinding brush. The pull rod is cylindrical, the middle part of the pull rod is the rod shaft 1, and one end of the pull rod is a fixed end for clamping on a pneumatic drill or an electric drill. 3. The other end of the pull rod is the connection end 2 connected with the grinding brush. The center of the connection end 2 is processed with an internal thread, and one end of the connection rod 6 of the grinding brush is processed with an external thread and the internal thread of the connection end 2 of the pull rod is clockwise. The other end of the connecting rod 6 of the grinding brush is connected to a cylindrical grinding head 4, and the connecting end surface of the grinding head 4 and the connecting rod 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com