Drying drum and dryer with same

A drum and cylinder technology, applied in the field of material drying equipment, can solve the problems of hollow drying drum, concentrated material throwing position, small contact area of material and heating airflow, etc., to improve thermal efficiency and increase contact heat exchange area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0032] In the present invention, in the case of no contrary description, the used orientation words such as "up, down, left and right" usually refer to the up, down, left and right shown in the accompanying drawings; "inside and outside" Refers to the inside and outside of the outline of each part itself.

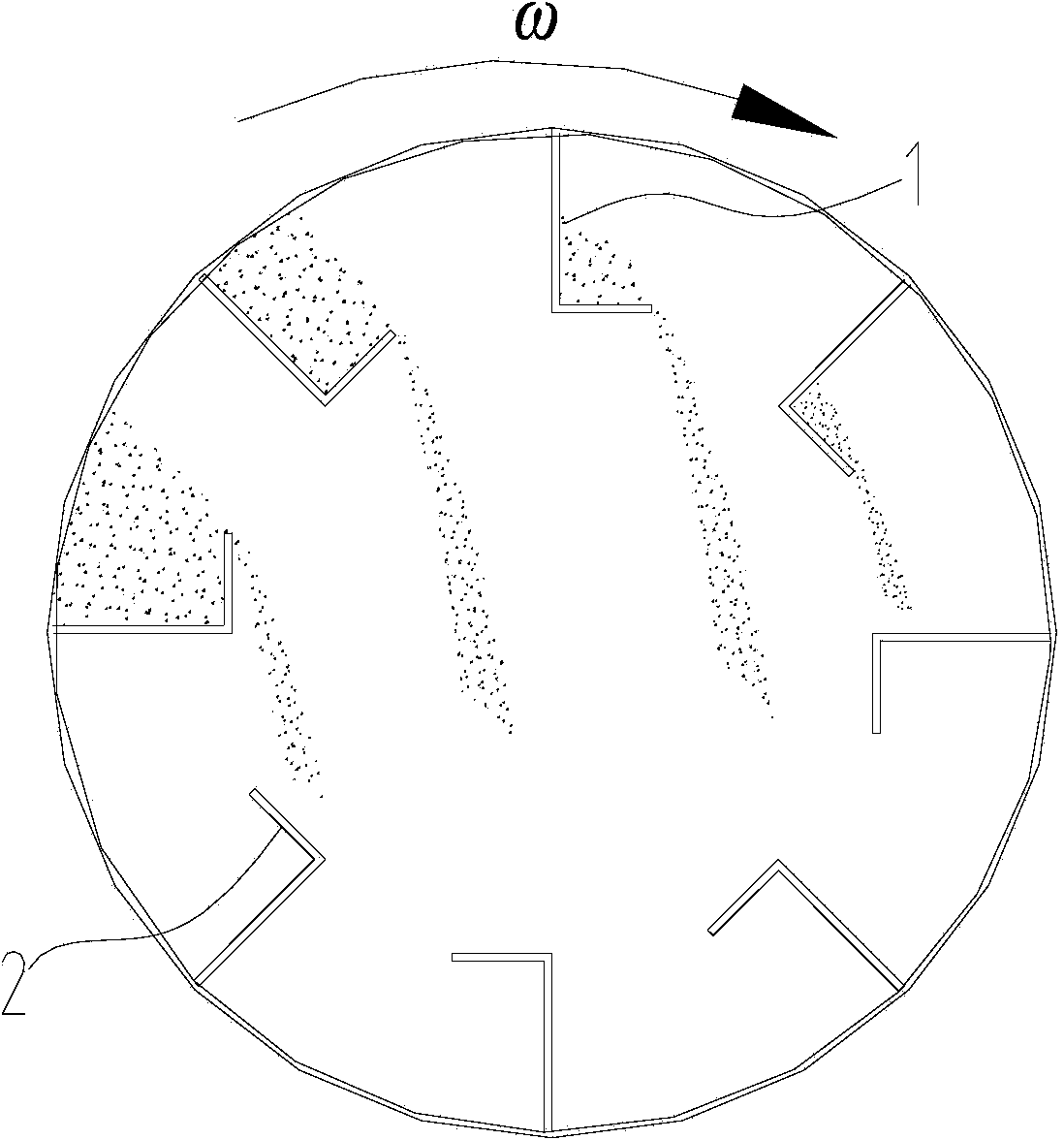

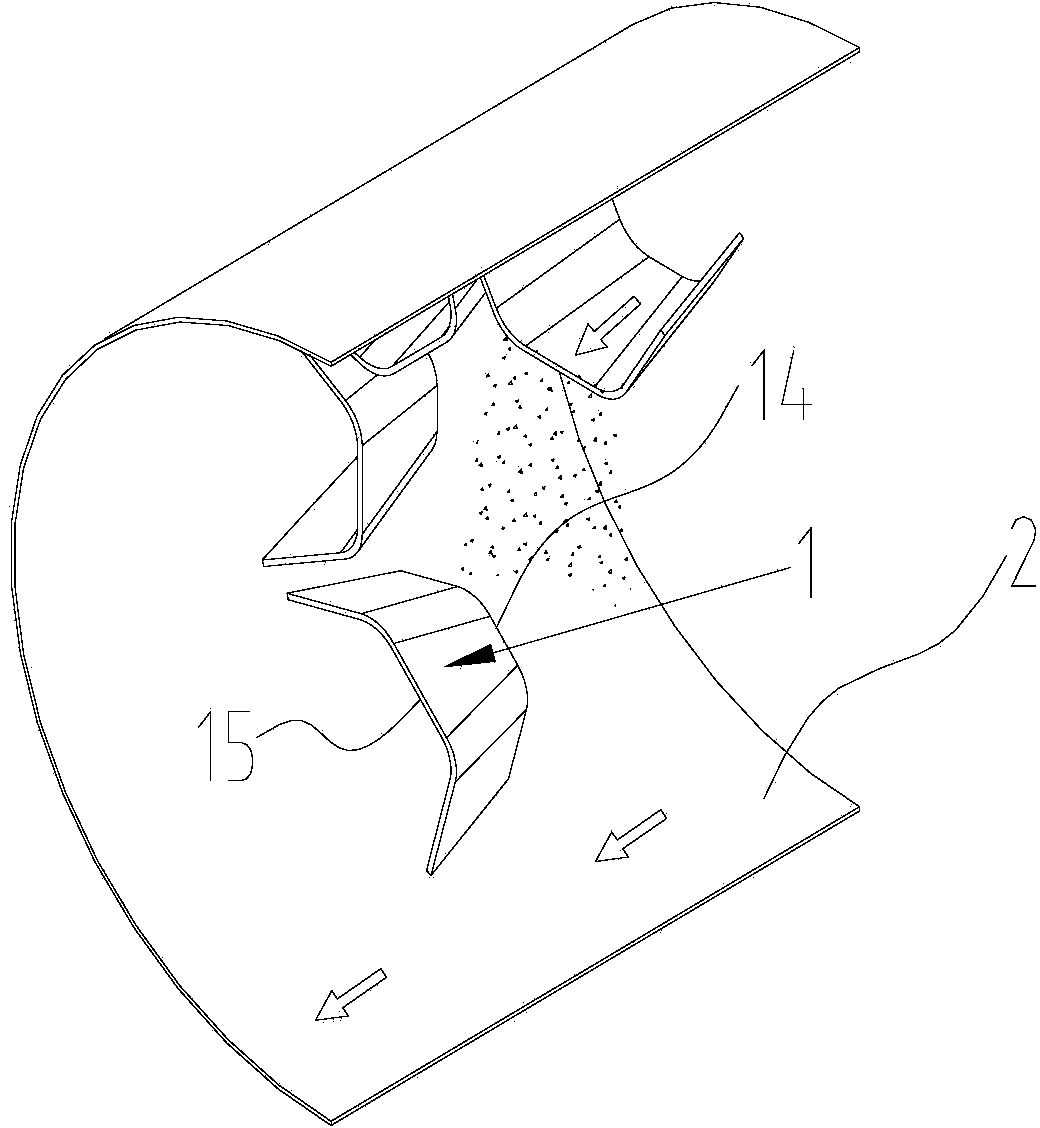

[0033] Such as Figure 3 to Figure 8 As shown, the present invention provides a drying drum, comprising a cylinder body 2, the cylinder body 2 has a feed inlet and a discharge port arranged oppositely, and a material lifting plate 1 is fixedly arranged on the inner wall surface of the cylinder body 2, wherein the lifting The feed port 14 of the material pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com