Cryogenic Butterfly Valve with Composite Dispersion Disc Bonnet

A heat dissipation plate and valve cover technology, applied in valve heating/cooling devices, valve lifts, valve details, etc., can solve the problems of small convection area between cold temperature and ambient temperature, insufficient sealing specific pressure, frequent replacement, etc. To avoid scratching the valve stem and packing, to ensure the opening and closing action of the valve, and to prevent the effect of freezing and sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

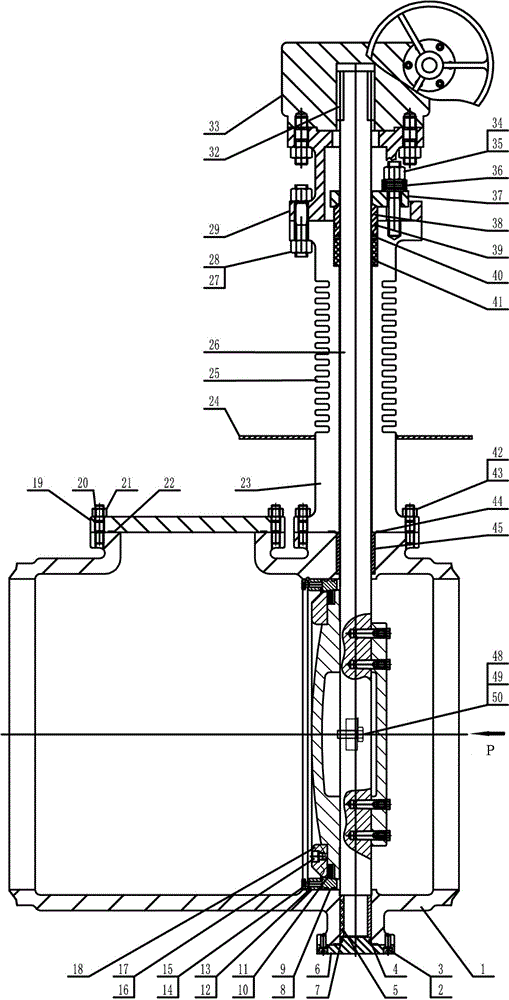

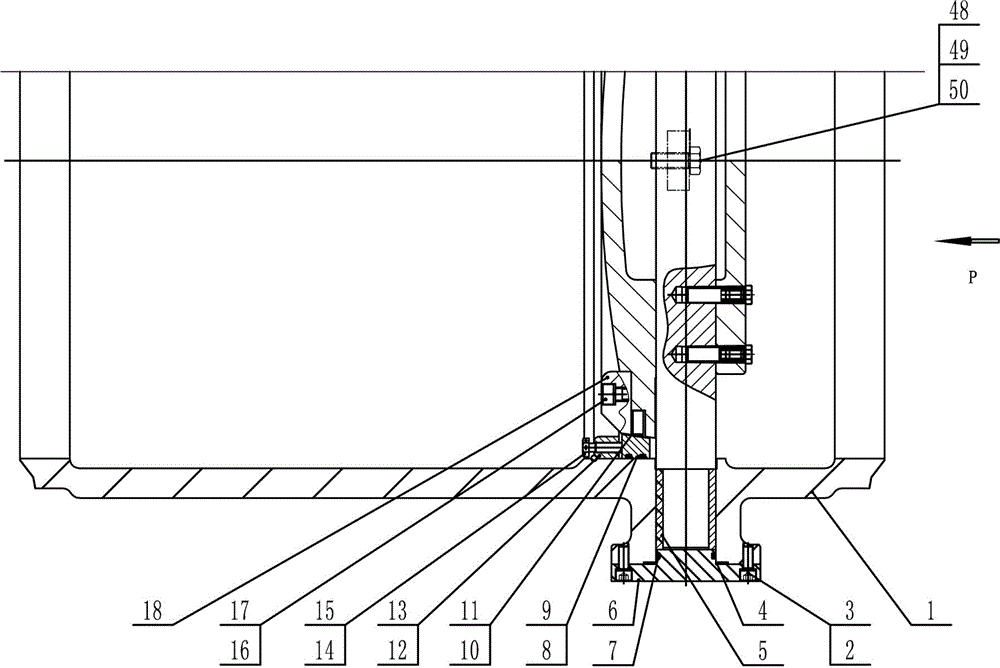

[0028] See attached Figure 1-2 As shown, a composite cooling disc bonnet cryogenic butterfly valve includes a valve body 1 in which a butterfly plate assembly and an axial floating valve seat assembly are formed, and the butterfly plate assembly and the axial floating valve seat assembly are formed Sealing structure, the valve stem 26 passes through the butterfly plate assembly and is fixed with the butterfly plate assembly, passes through the upper and lower shaft holes of the valve body, passes upwards through the bonnet 23, and connects with the graphite packing layer 41 in the upper sealing box of the bonnet. The actuator assembly 33, which extends upward through the bracket 29, drives the butterfly plate assembly by rotating 90°; the graphite packing is provided with a packing pressure sleeve 38 above the graphite packing. There is a packing gland 37 on the top, and the packing gland is fixedly connected with the valve cover; the outside of the valve cover is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com