Normal-temperature rapid phosphating solution and preparing method thereof

A phosphating solution, fast technology, applied in the field of phosphating solution, can solve the problems of carcinogenicity, environmental pollution, violent explosive reaction, etc., and achieve the effects of improving production efficiency, short phosphating time, and low use temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

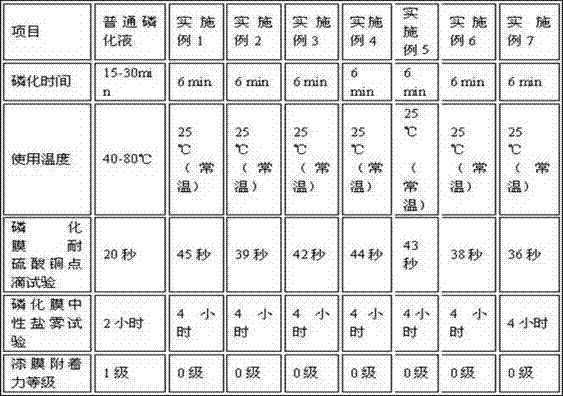

Examples

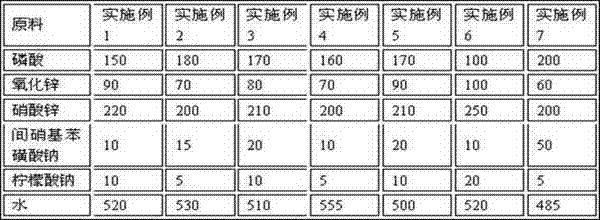

Embodiment 1

[0044]Every 1000Kg room temperature rapid phosphating solution is made of the following raw materials:

[0045] Phosphoric acid 150Kg, zinc oxide 90 Kg, zinc nitrate 220 Kg, sodium m-nitrobenzene sulfonate 10 Kg, sodium citrate 10 Kg, water 520 Kg.

[0046] Its preparation method comprises the following steps in turn:

[0047] (1) Add phosphoric acid into the reactor, open the reactor and stir;

[0048] (2) Add 50% of the total amount of water required into the reactor;

[0049] (3) Add zinc oxide into the reaction kettle until the reaction is complete and the solution is clear (about 4 hours);

[0050] (4) Add the remaining 50% of water to the reactor;

[0051] (5) Add zinc nitrate to the reaction kettle, stir well and the solution is clear (about 2 hours);

[0052] (6) Add sodium m-nitrobenzenesulfonate into the reaction kettle, wait until it is evenly stirred and the solution is clarified (about 1 hour);

[0053] (7) Add sodium citrate into the reaction kettle, stir we...

Embodiment 2

[0056] Every 1000Kg room temperature rapid phosphating solution is made of the following raw materials:

[0057] Phosphoric acid 180Kg, zinc oxide 70Kg, zinc nitrate 200Kg, sodium m-nitrobenzenesulfonate 15Kg, sodium citrate 5Kg, water 530Kg.

[0058] The preparation method is the same as in Example 1.

Embodiment 3

[0060] Every 1000Kg room temperature rapid phosphating solution is made of the following raw materials:

[0061] Phosphoric acid 170Kg, zinc oxide 80Kg, zinc nitrate 210Kg, sodium m-nitrobenzenesulfonate 20Kg, sodium citrate 10Kg, water 510Kg.

[0062] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com