Internally heated coal carbonization furnace, internally heated coal carbonization system and coal carbonization technical method

A coal dry distillation and internal heating technology, which is applied in special forms of dry distillation, direct heating dry distillation, coking oven with vertical carbonization chamber, etc., can solve the problem of reducing the yield of semi-coke products, reducing the combustion and thermal efficiency of the combustion chamber, and limiting the coking process and efficiency, to simplify the mechanical structure and working principle, reduce design and construction costs, and improve effective space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0070] The invention includes two parts: the structure design and the technology of the internal heating type coal carbonization furnace.

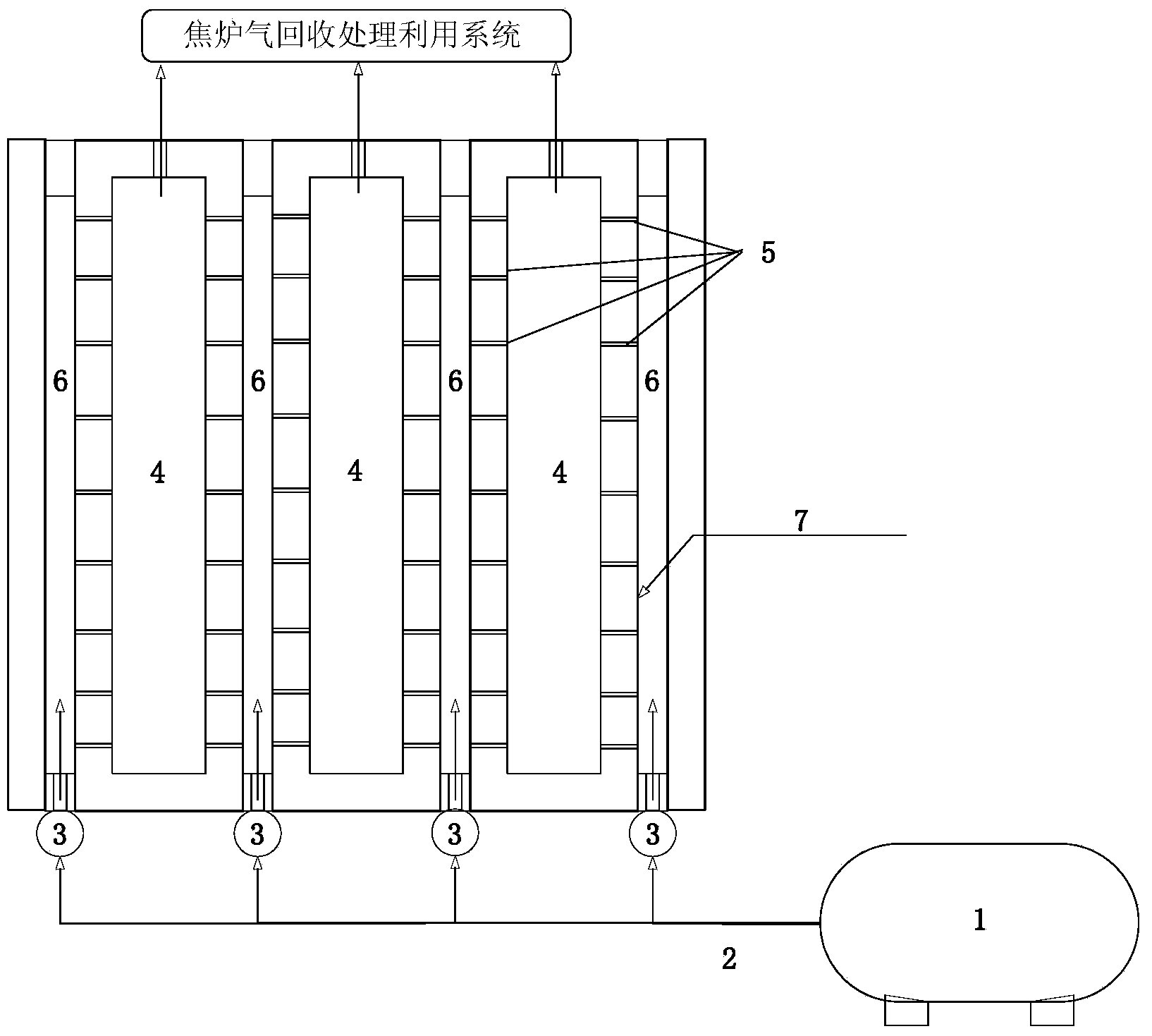

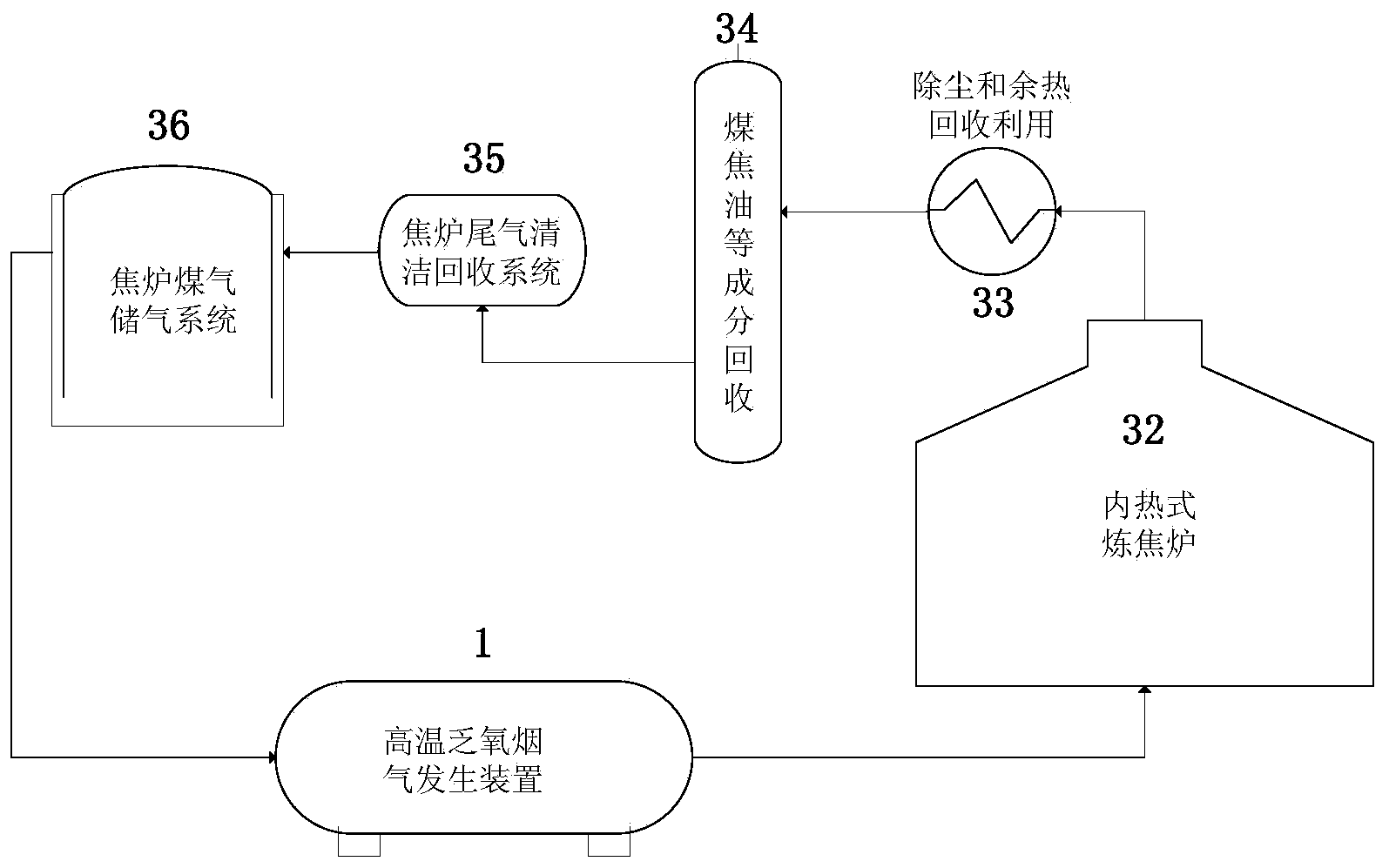

[0071] Internal heating type coal carbonization furnace of the present invention, its structure is as follows figure 1 Shown (internal heating type coal carbonization furnace described in the present invention, has canceled coal gas and air transmission and distribution system and relevant auxiliary system. figure 1 The other units, structure, equipment, process technology and flow of the coal carbonization furnace not shown in the above can be the same as the modern coal carbonization furnace, and are implemented by using the existing technology, and will not be described in detail. ),include:

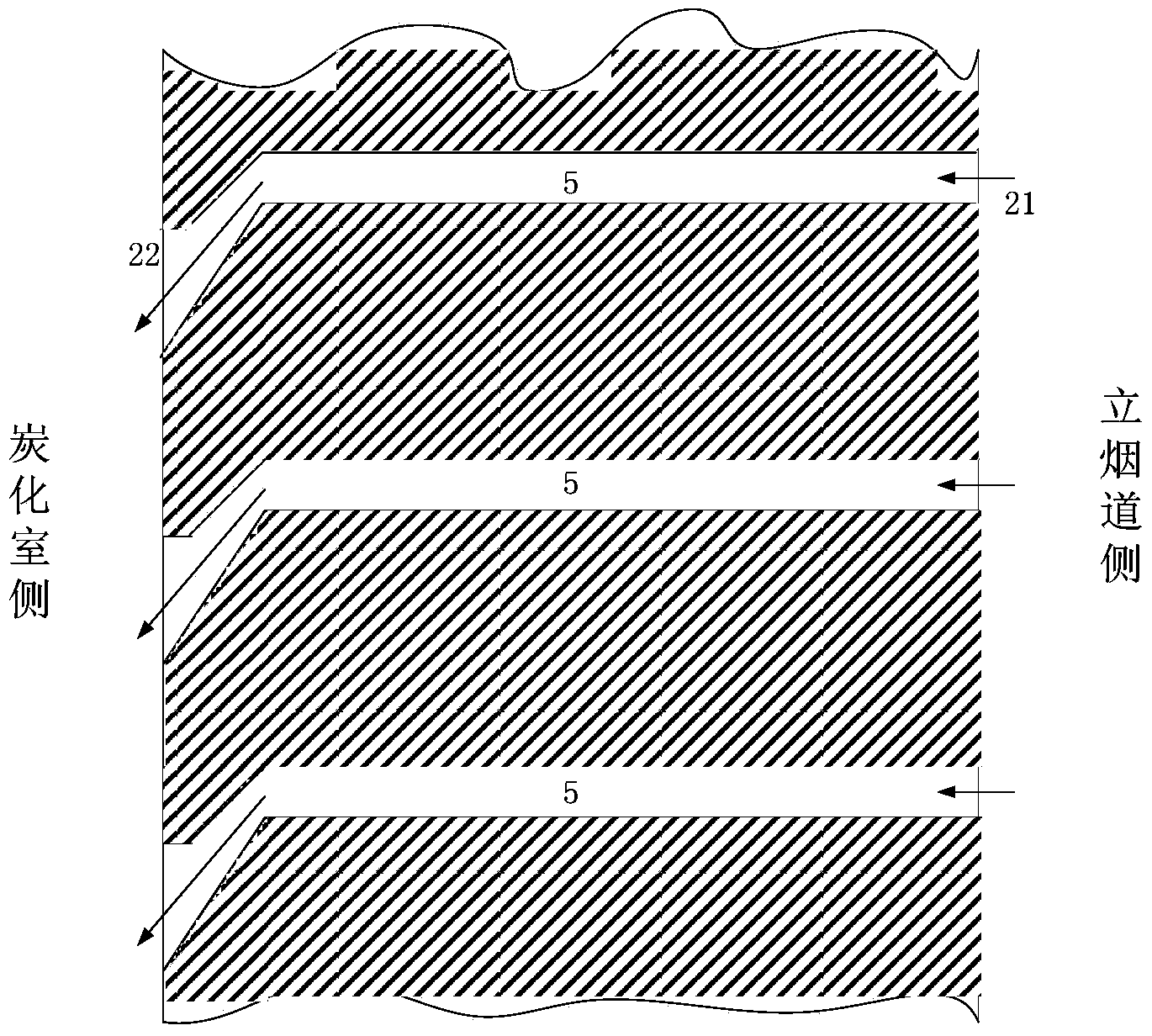

[0072] Furnace body, the furnace body is provided with several carbonization chambers 4 side by side, the carbonization cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com