Water-based metal package barrel color paint and preparing method of color paint

A metal packaging, water-based technology, applied in the field of coatings, can solve problems such as mutual bleeding of water-based metal packaging barrels, and achieve the effect of solving the problem of color separation, saving oil resources, and protecting the ecological environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

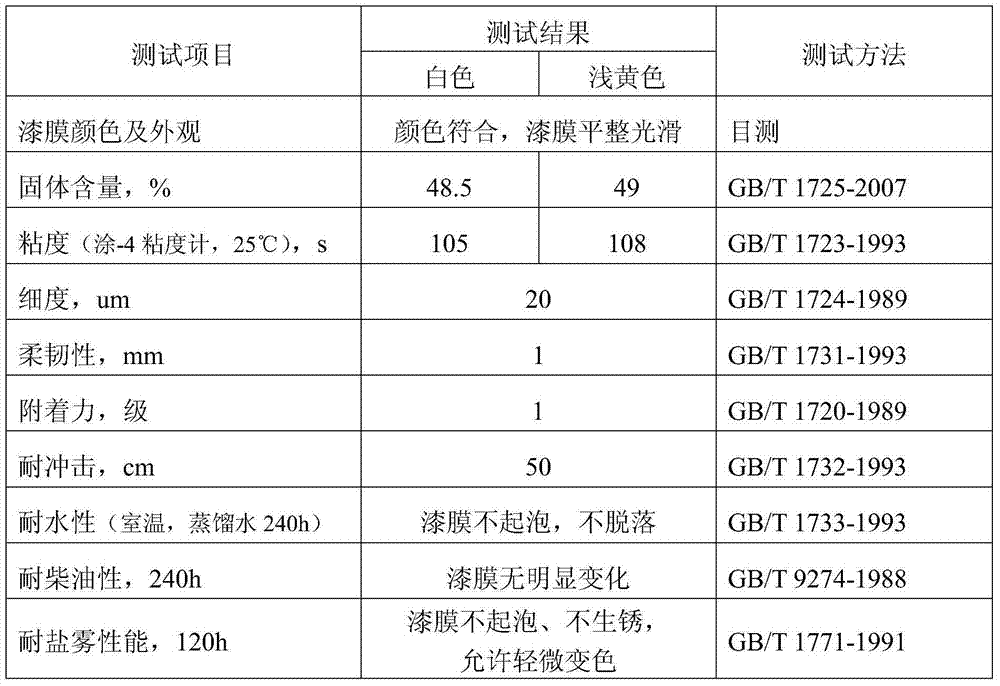

Embodiment 1

[0023] A preparation method of a color-separation paint for a white metal packaging barrel, comprising the steps of:

[0024] Under the condition of stirring at 500r / min, add 20 parts of deionized water, 0.2 parts of BYK-020 (defoamer), 2 parts of BYK-190 (dispersant), RD-1050H water-dilutable polyester resin into the paint mixing tank 22.5 parts, stir evenly, then add 20 parts of R-902 titanium dioxide, 10 parts of 801A precipitated barium sulfate, continue to stir evenly, enter the sand mill and grind until the fineness is ≤20um;

[0025] Pump the solution with qualified fineness back into the paint mixing tank, and then add 22.5 parts of RD-1050H water-dilutable polyester resin and SF-9090 water-based leveling agent (water-based silicone leveling agent) under the condition of 500r / min stirring 1 part, 0.6 parts of RAYBO-60 anti-flash rust agent, 10 parts of M-03 amino resin, and then stir for 30 minutes to get white water-based color separation paint for metal packaging bar...

Embodiment 2

[0028] A preparation method of light yellow metal packaging barrel color separation paint, comprising the steps of:

[0029] Under the condition of stirring at 500r / min, add 20 parts of deionized water, 0.2 parts of BYK-020 (defoamer), 2 parts of BYK-190 (dispersant), RD-1050H water-dilutable polyester resin into the paint mixing tank 22.5 parts, stir well, then add 20 parts of R-902 titanium dioxide, 10 parts of 801A precipitated barium sulfate, 0.5 parts of OP-206 permanent yellow, continue to stir evenly, enter the sand mill to grind to a fineness ≤ 20um;

[0030] Pump the solution with qualified fineness back into the paint mixing tank, and then add 22.5 parts of RD-1050H water-dilutable polyester resin and SF-9090 water-based leveling agent (water-based silicone leveling agent) under the condition of 500r / min stirring 1 part, 0.6 parts of RAYBO-60 anti-flash rust agent, 10 parts of M-03 amino resin, and then stir for 30 minutes to get light yellow water-based color separa...

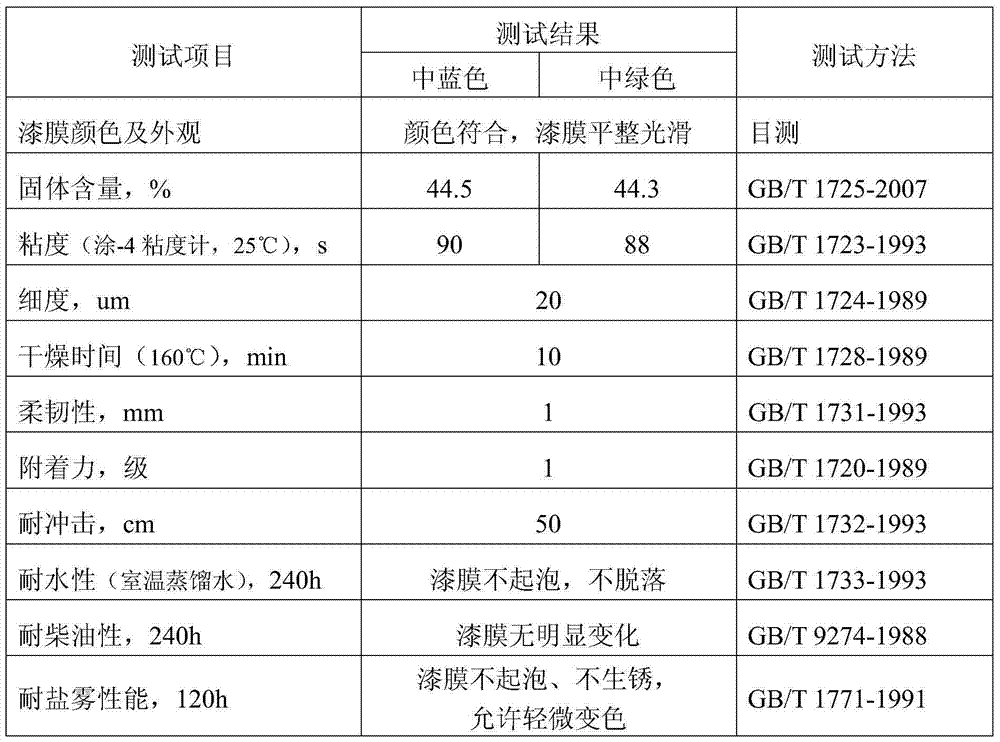

Embodiment 3

[0035] A method for preparing a medium-blue water-based color separation paint for metal packaging barrels, comprising the steps of:

[0036] Under the stirring condition of 500r / min, add 20 parts of deionized water, 0.2 parts of BYK-020 (defoamer), 3 parts of BYK-190 (dispersant), RD-1050H water-dilutable polyester resin into the paint mixing tank 22.5 parts, stir evenly, then add 10 parts of R-902 titanium dioxide, 10 parts of 801A precipitated barium sulfate, 10 parts of 15:3 phthalocyanine blue, continue to stir evenly, enter the sand mill to grind to a fineness ≤ 20um;

[0037] Pump the solution with qualified fineness back into the paint mixing tank, and then add 22.5 parts of RD-1050H water-dilutable polyester resin and leveling agent DAPRO U-99 (water-based acrylic leveling agent) under the condition of 500r / min stirring 1 part, 0.6 part of RAYBO-60 anti-flash rust agent, 10 parts of M-03 amino resin, and then stir for 30 minutes to get a medium blue water-based color ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com