Continuous synthesis method for polyether

A polyether and low molecular weight polyether technology, applied in the field of continuous synthesis of polyethers, can solve the problems of loss of activity, large tailing of small molecules, decreased activity of DMC, etc. The effect of low molecular tailing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

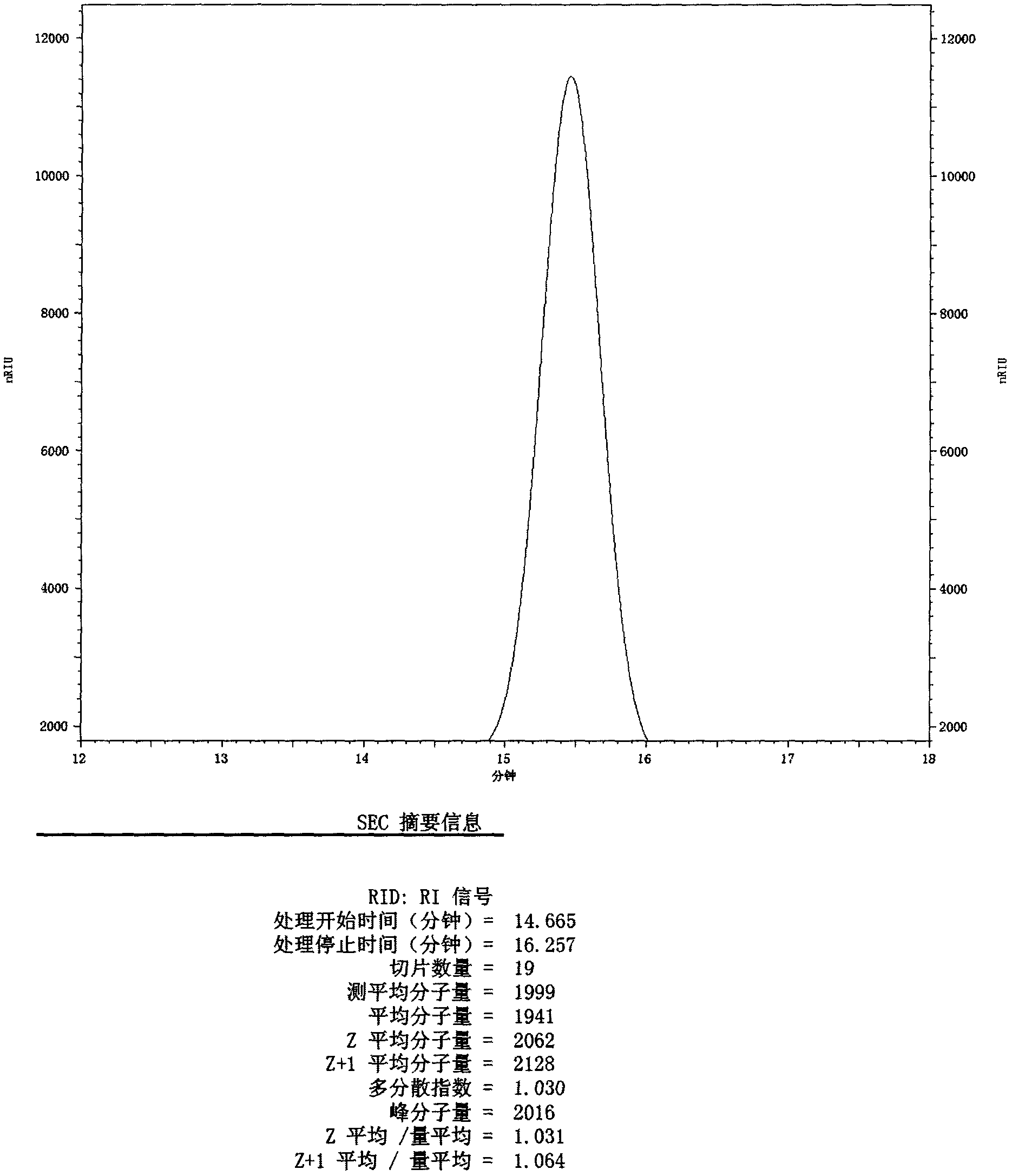

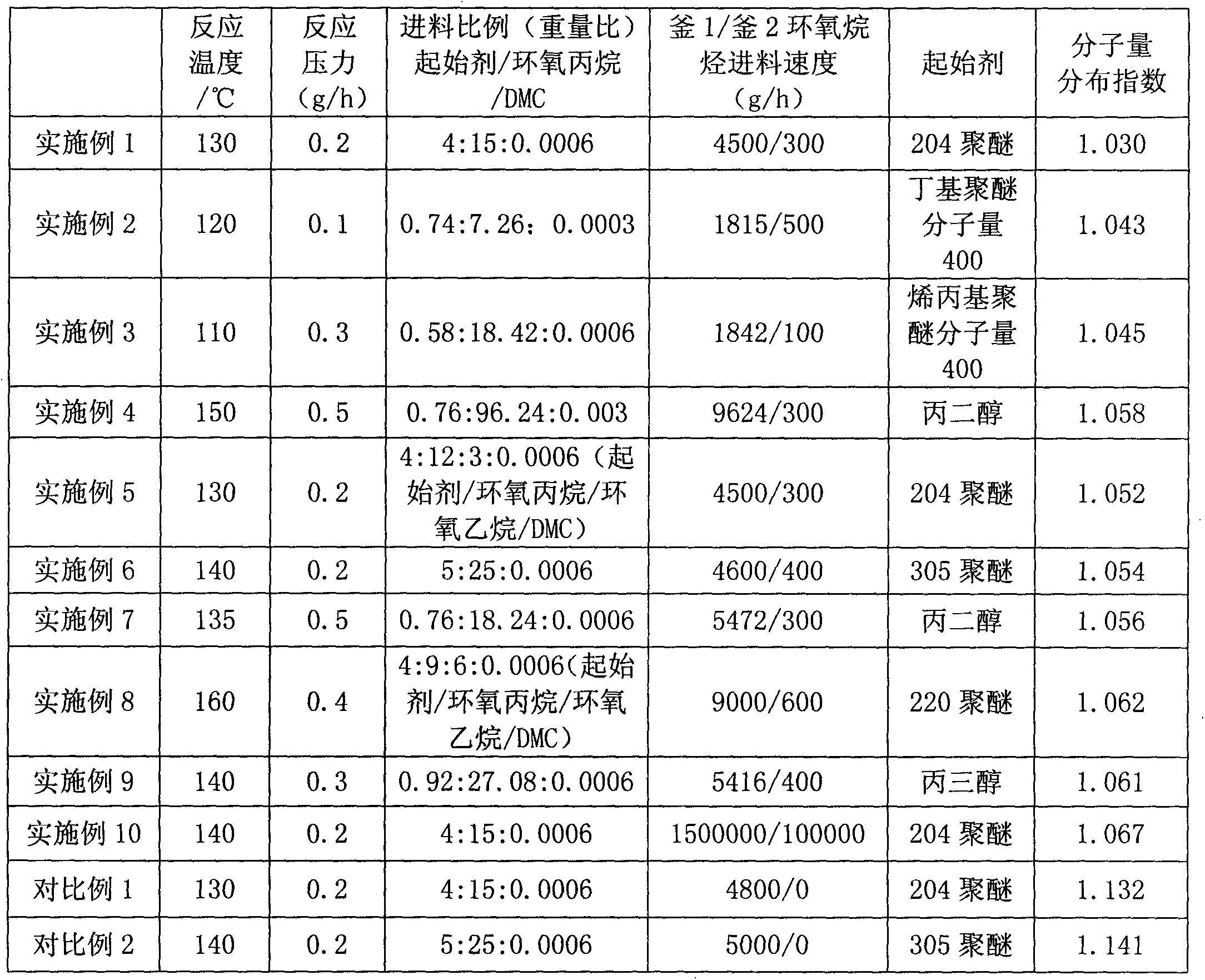

Embodiment 1

[0020] In 5 liters of reactors 1, add the initiator 204 polyethers of 400g (the polyoxypropylene diol of two-functionality molecular weight 400, the same below) and 0.060gDMC catalyst, vacuum dry, slowly add 80g propylene oxide after drying completes, Maintain 130°C for induction reaction. When the temperature keeps rising and the pressure keeps falling, it indicates that the catalyst has been induced to activate. After the induction was completed, 1420 g of propylene oxide was continuously added to the reaction kettle 1 at a temperature of 0.2 MPa while maintaining 130° C. Then feed propylene oxide at a speed of 4500g / h, and simultaneously add 204 polyether and DMC catalyst in a ratio of 4:15:0.0006 by weight ratio of 204 polyether / propylene oxide / DMC. After the reactor 1 is full, the materials enter the reactor 2, maintain the temperature of the reactor 2 at 130° C., and the pressure at 0.2 MPa, and add propylene oxide to the reactor 2 at a feeding rate of 300 g / h. After t...

Embodiment 2

[0022] Add 800 g of initiator butyl polyether (molecular weight: 400) and 0.060 g of DMC catalyst to 5 liters of reactor 1, vacuum dry, slowly add 80 g of propylene oxide after drying, and maintain 120°C for induction reaction. When the temperature keeps rising and the pressure keeps falling, it indicates that the catalyst has been induced to activate. After the induction was completed, 720 g of propylene oxide was continuously added at 0.1 MPa while maintaining 120°C. Then pass into propylene oxide according to the speed of 1815g / h, be 0.74:7.26:0.0003 ratio to add n-butanol and DMC catalyst simultaneously by n-butanol / propylene oxide / DMC weight ratio. After the reactor 1 is full, the material enters the reactor 2, maintains the temperature at 120° C. and the pressure at 0.1 MPa, and feeds propylene oxide into the reactor 2 at a feed rate of 500 g / h. After the reactor 2 is full, the material is discharged continuously to obtain the butyl polyether product. The hydroxyl valu...

Embodiment 3

[0024] Add 400 g of allyl polyether (molecular weight: 400) and 0.060 g of DMC catalyst into 5 liters of reactor 1, vacuum dry, slowly add 80 g of propylene oxide after drying, and maintain 110° C. for induction reaction. When the temperature keeps rising and the pressure keeps falling, it indicates that the catalyst has been induced to activate. After the induction was completed, 1420 g of propylene oxide was continuously added at 0.3 MPa while maintaining 110°C. Then pass into propylene oxide according to the speed of 1842g / h, be 0.58: 18.42: 0.0006 ratio to add allyl alcohol and DMC catalyst simultaneously by allyl alcohol / propylene oxide / DMC weight ratio. After the reactor 1 is full, the material enters the reactor 2, maintains the temperature at 110°C and the pressure at 0.3MPa, and feeds propylene oxide into the reactor 2 at a rate of 100g / h. After the reactor 2 is full, the material is discharged continuously to obtain the allyl polyether product. The hydroxyl value o...

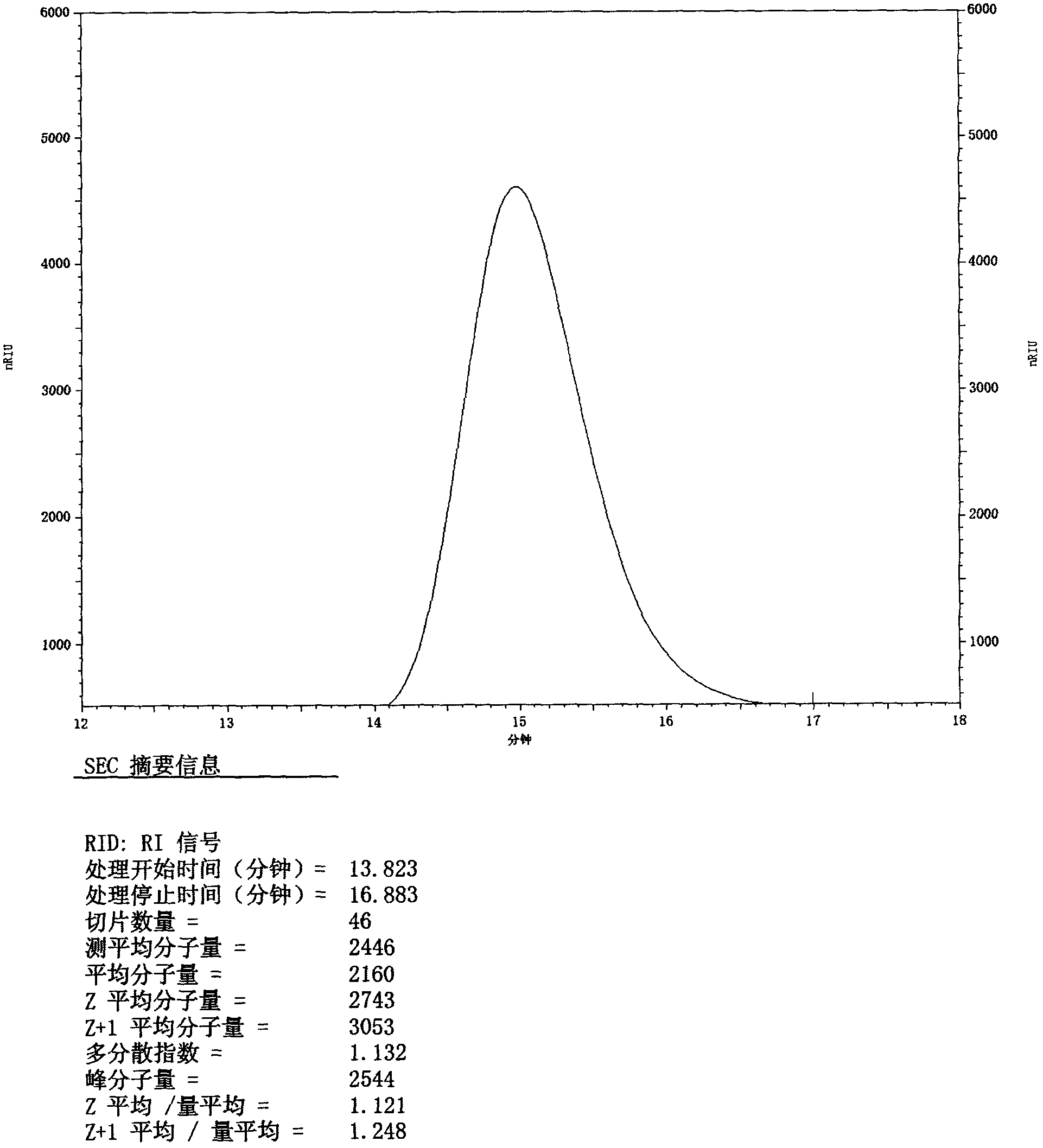

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com