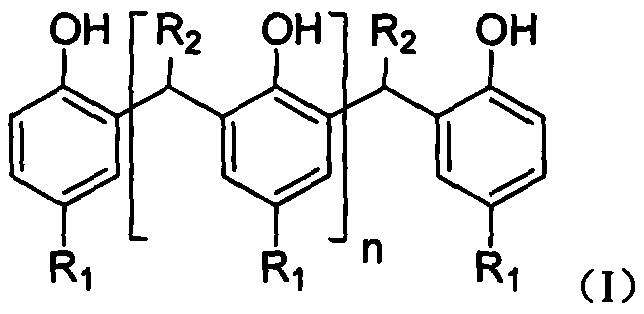

Preparation method for modified alkyl phenolic resin and application thereof

An alkyl phenolic resin and modification technology, applied in the field of phenolic resin, can solve the problems of increased fuel consumption, energy loss, accelerated aging speed of rubber materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

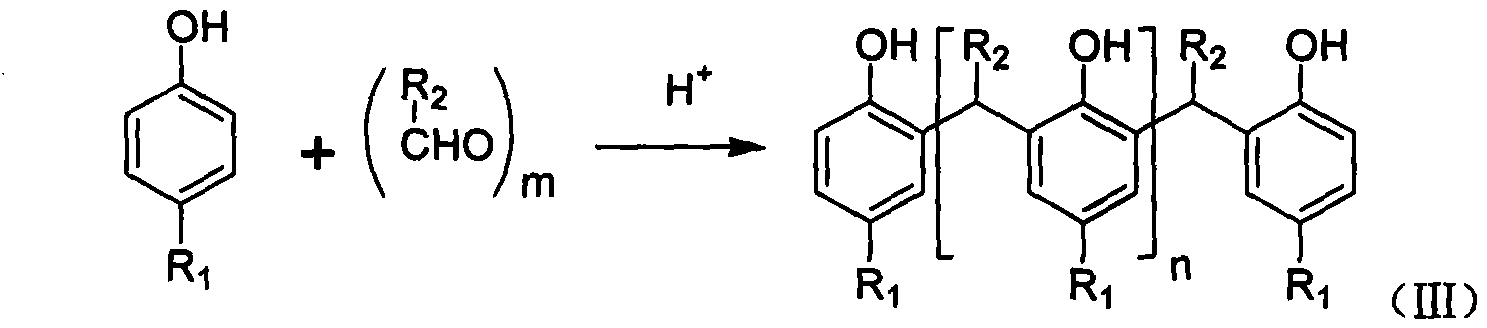

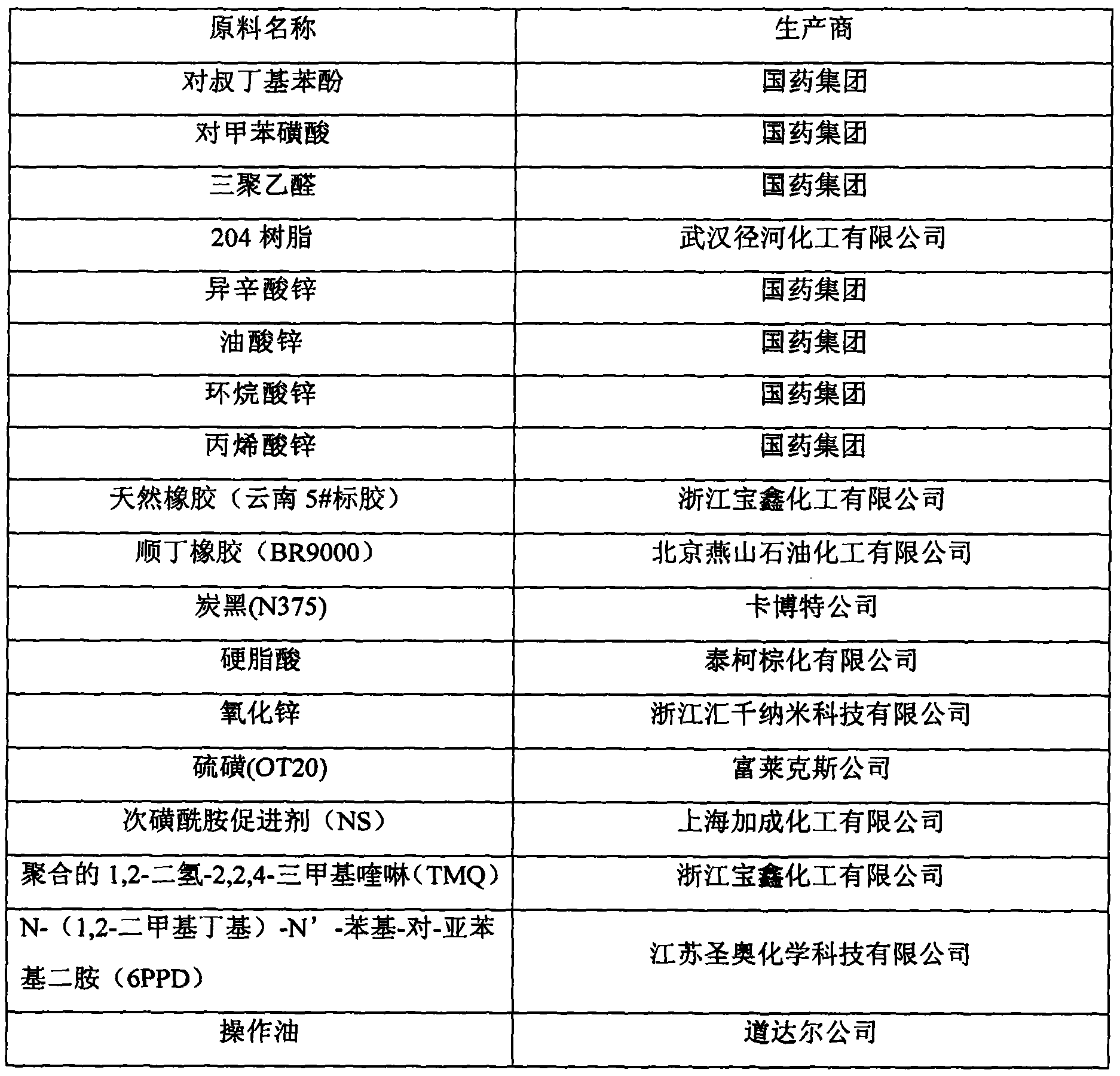

Method used

Image

Examples

Embodiment 1

[0035] Into a 500ml four-necked round-bottomed reaction flask equipped with a mechanical stirrer, thermometer, reflux condenser and dropping funnel, add 150g (1.0mol) p-tert-butylphenol (PTBP) and 0.75g p-toluenesulfonic acid (catalyst) , and heat the mixture to 150 °C. When the temperature was 150°C, 132g (1.0 mole) of paraldehyde was slowly added dropwise, the condenser changed from the reflux state to the distillation state, and the reaction temperature gradually rose to 180°C. After the dropwise addition of paraldehyde was completed, keep it for 10 minutes , then add 0.6g of 1,8-diazabicyclo (5,4,0)-7-undecene (DBU) to neutralize the catalyst, stir and react for 15 minutes, slowly open the vacuum to the maximum vacuum degree (2.5 K Pa) and keep for 30 minutes. The resin obtained by the reaction was poured out and cooled to obtain resin A. The softening point of this resin measured by ASTM D3461-97 (2007) was 145 degreeC.

Embodiment 2

[0037]Into a 500ml four-necked round-bottomed reaction flask equipped with a mechanical stirrer, thermometer, reflux condenser and dropping funnel, add 150g (1.0mol) p-tert-butylphenol (PTBP) and 0.75g p-toluenesulfonic acid (catalyst) , and heat the mixture to 150 °C. When the temperature is 150°C, 50g (0.379 moles) of paraldehyde is slowly added dropwise, the condenser changes from reflux state to distillation state, and the reaction temperature gradually rises to 180°C. After the dropwise addition of paraldehyde is completed, keep it for 10 minutes Then add 10g92% paraformaldehyde (0.307 moles), continue to react for 30 minutes and heat up to 210°C, add 0.6g of 1,8-diazabicyclo(5,4,0)-7-undecene (DBU) to neutralize the catalyst, after stirring the reaction for 15 minutes, slowly turn on the vacuum to the maximum vacuum degree (2.5 kPa) and keep it for 30 minutes. The resin obtained by the reaction was poured out and cooled to obtain resin B. The softening point of this re...

Embodiment 3

[0039] Add 100 g of the resin A prepared according to Example 1 to a 250 mL three-neck flask equipped with a mechanical stirrer and a thermometer, heat up to 180 ° C and melt, add 1 g of zinc isooctanoate, stir for 10 minutes, pour out the resin, and cool to obtain a modified alkyl Phenolic Resin. The softening point of this resin measured by ASTM D3461-97 (2007) was 142 degreeC.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com