Core-shell type magnetic composite microsphere for separation and purification of recombinant proteins and preparation method thereof

A technology for separation and purification of magnetic composite microspheres, which is applied in peptide preparation methods, microsphere preparation, chemical instruments and methods, etc., can solve problems such as uneven particle size distribution, lack of surface, and high price, and achieve regular structure, The effect of simple preparation process and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Core-shell Fe with a layer thickness of about 50 nm and a cross-linking degree of 75% 3 O 4 / PMG / IDA-Ni 2+ Microspheres

[0040] 1. Preparation of sodium citrate-stabilized magnetic clusters

[0041] 1.3g of ferric chloride hexahydrate (FeCl 3 ·6H 2 O), 3.8 g ammonium acetate (NH 4 Ac), after 0.4g of sodium citrate was dissolved in 70mL of ethylene glycol, it was added to a 150mL three-necked flask, then heated to 160°C, and after the reaction was incubated for 1h, the liquid in the flask was transferred into a 100mL-containing polytetrafluoroethylene lined high-pressure reaction kettle, and then put the reaction kettle into a 200 ℃ oven for 16 hours, take it out, and cool it to room temperature with tap water. The product is separated by magnetic separation, and the unreacted reactant is removed by washing with absolute ethanol, and finally the product is dispersed in absolute ethanol for subsequent use;

[0042] 2. Active vinyl modification on the su...

Embodiment 2

[0050] Example 2: Preparation of core-shell Fe with a shell thickness of about 50 nm and a cross-linking degree of 60% 3 O 4 / PMG / IDA-Ni 2+ Microspheres

[0051] 1. The preparation of sodium citrate-stabilized magnetic clusters is the same as described in Example 1-1;

[0052] 2. The active vinyl modification on the surface of the magnetic cluster is the same as that described in Example 1-2;

[0053] 3. Core-shell Fe 3 O 4 The preparation of / PMG is the same as that described in Examples 1-3, and the dosages of glycidyl methacrylate and 2,2-azobisisobutyronitrile in this example are 200 μL and 10 mg, respectively;

[0054] 4. The ring-opening reaction of iminodiacetic acid is the same as described in Example 1-4;

[0055] 5. Complex Ni 2+ The reactions are as described in Examples 1-5.

Embodiment 3

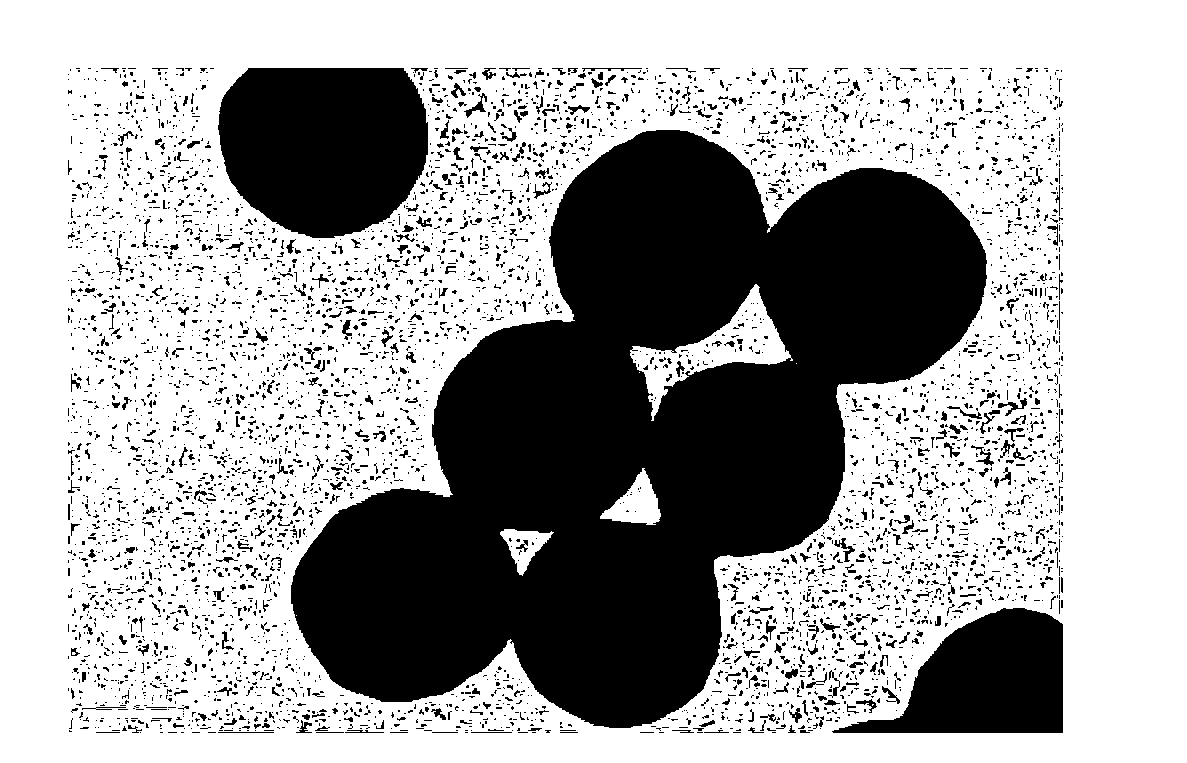

[0056] Example 3: Preparation of core-shell Fe with a shell thickness of about 50 nm and a cross-linking degree of 50% 3 O 4 / PMG / IDA-Ni 2+ Microspheres (such as figure 1 shown)

[0057] 1. The preparation of sodium citrate-stabilized magnetic clusters is the same as described in Example 1-1;

[0058] 2. The active vinyl modification on the surface of the magnetic cluster is the same as that described in Example 1-2;

[0059] 3. Core-shell Fe 3 O 4 The preparation of / PMG is the same as that described in Examples 1-3; in this example, the dosages of glycidyl methacrylate and 2,2-azobisisobutyronitrile are 300 μL and 12 mg, respectively;

[0060] 4. The ring-opening reaction of iminodiacetic acid is the same as described in Example 1-4;

[0061] 5. Complex Ni 2+ The reactions are as described in Examples 1-5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com