High speed composting method using AT-18 enzyme composition

A technology of AT-18, composting method, applied in the direction of application, organic fertilizer, fertilization device, etc., can solve the problems of damaged plant growth, loss of soil, residues, etc., to achieve the effect of short heating time, energy saving, and small processing site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

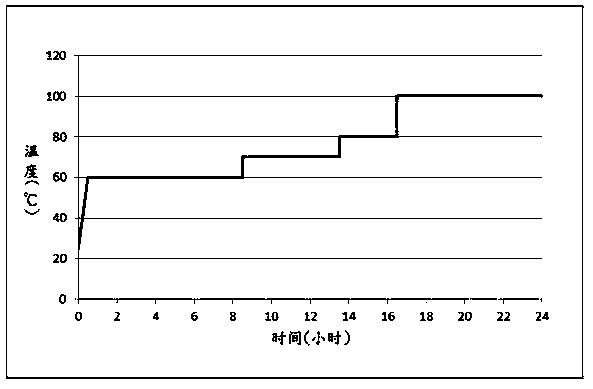

[0021] see figure 2 Shown is the heating time curve of the fermenter in a preferred embodiment of the present invention. As shown in the figure, before heating the fermentation machine, in order to shorten the fermentation time, the organic waste is pre-treated, depending on the organic waste, it can be crushed, ground, shredded, shredded or cut, etc. The way to crush, to achieve the appropriate particle size. Adjust the carbon-nitrogen ratio of the organic waste; since there are many types of organic waste with large differences in composition, understanding the characteristics and composition of different types of compost will help to assist in judging the mixing ratio of different wastes and fertilization management methods to improve composting. Fermentation efficiency and organic fertilizer output.

[0022] The following table shows the carbon-nitrogen ratio, organic matter and other inorganic compound content of different compost raw materials:

[0023]

[0024] G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com