Axial and radial combined type fixed bed catalytic reactor for olefince oxidative dehydrogenation

A catalytic reactor, oxidative dehydrogenation technology, applied in the direction of hydrocarbons, hydrocarbons, chemical instruments and methods, etc., can solve the problems of axial fixed bed reactors that cannot be enlarged, front heat exchanger design and operation inconvenience, front Problems such as large heat exchanger load, to achieve the effect of improving space utilization, high energy utilization, and increasing loading capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

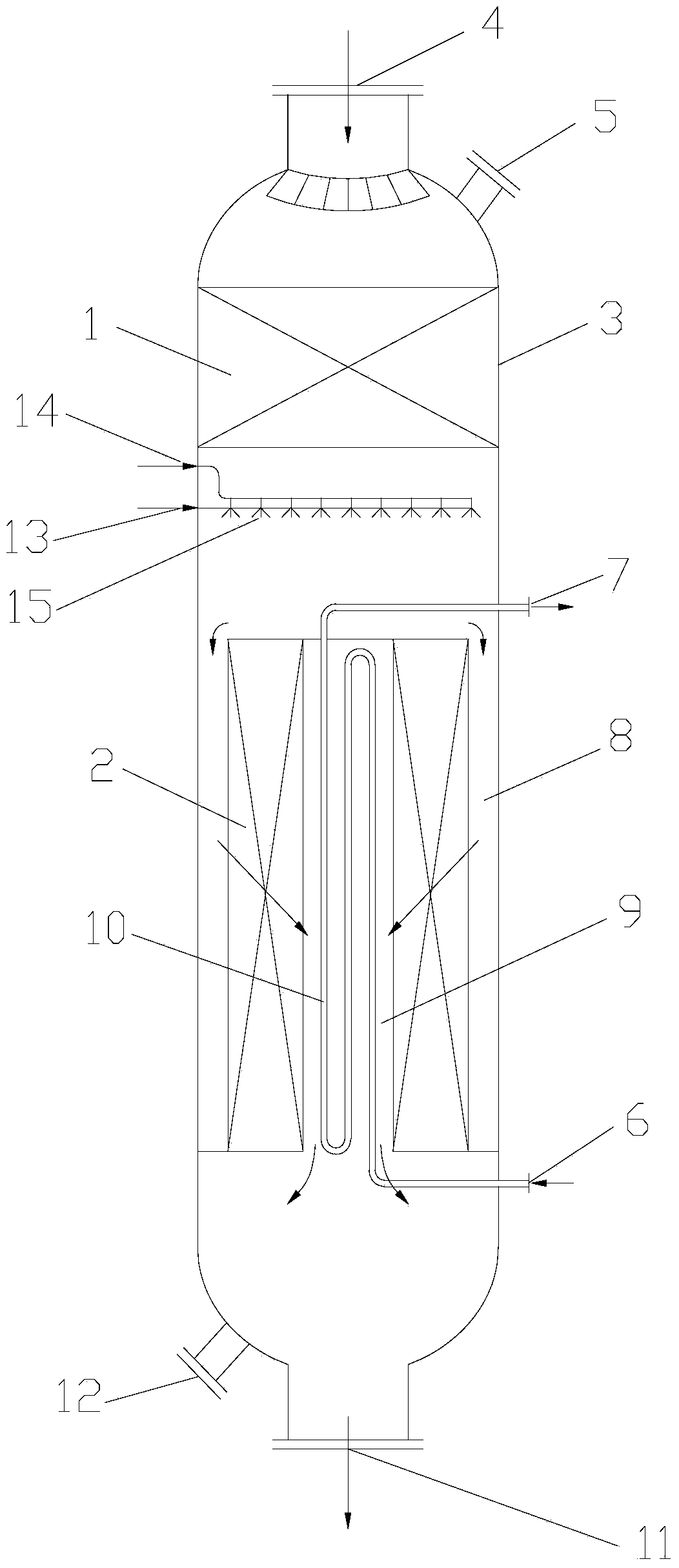

[0036] Such as figure 1 Shown, a kind of axial radial composite fixed-bed catalytic reactor that is used for oxidative dehydrogenation of butene, comprises cylindrical reactor shell 3, the raw material gas inlet 4 that this reactor shell top is set, the bottom set The product gas outlet 11 and the feed gas inlet 4 are provided with a distributor, which is provided with an axial reaction section 1, a radial reaction section 2 and an inter-stage quenching section in the reactor shell 3, and the inter-stage The quenching section is located between the axial reaction section 1 and the radial reaction section 2; wherein the radial reaction section 2 is in the form of centripetal flow, and the axial reaction section 1 is arranged at the upper end of the radial reaction section 2 . The height range of the axial reaction section is 300-800mm. The thickness range of the radial reaction section is 200-800mm.

[0037] The axial reaction section 1 includes an axial section cylinder and ...

Embodiment 2

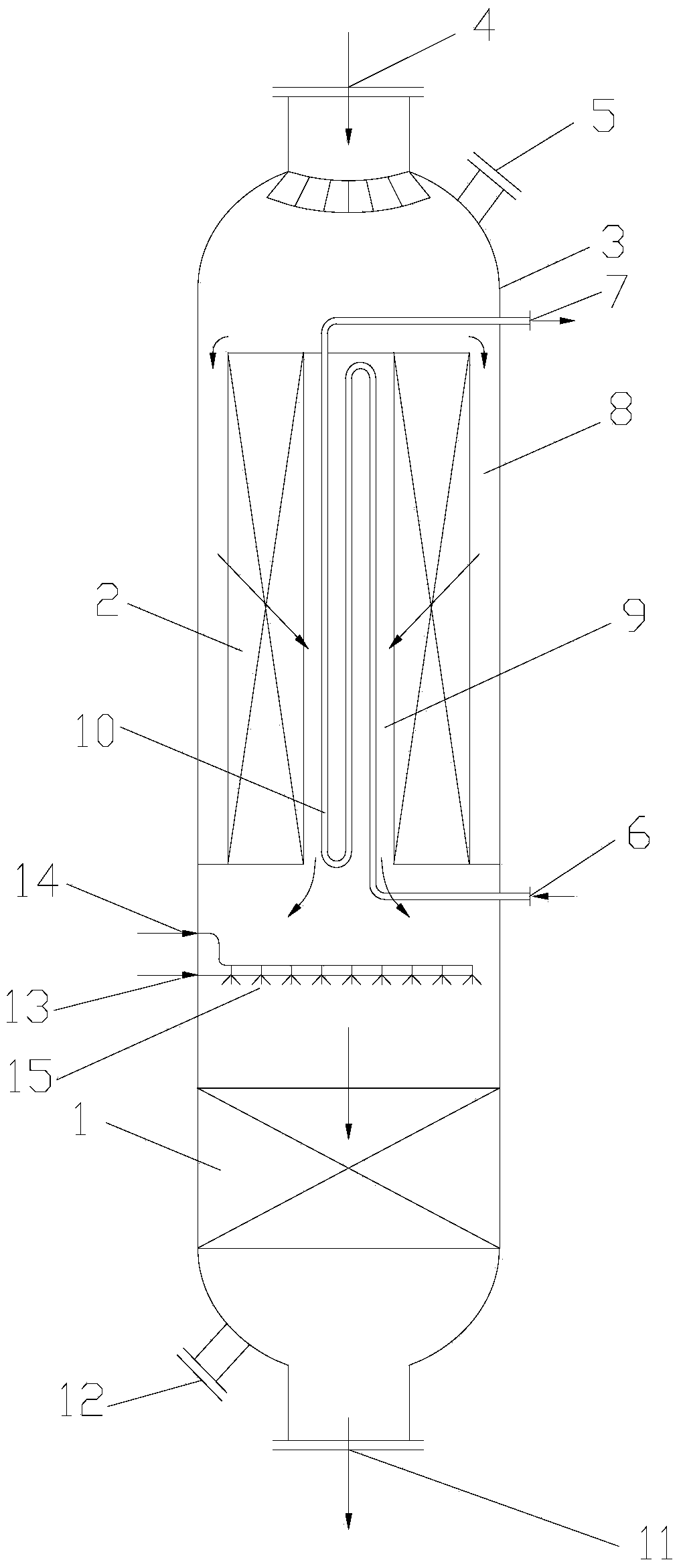

[0043] Such as figure 2 Shown, a kind of axial radial composite fixed-bed catalytic reactor that is used for oxidative dehydrogenation of butene, comprises cylindrical reactor shell 3, the raw material gas inlet 4 that this reactor shell top is set, the bottom set The product gas outlet 11 and the feed gas inlet 4 are provided with a distributor, which is provided with an axial reaction section 1, a radial reaction section 2 and an inter-stage quenching section in the reactor shell 3, and the inter-stage The quenching section is located between the axial reaction section 1 and the radial reaction section 2; wherein the radial reaction section 2 is in the form of centripetal flow, and the axial reaction section 1 is arranged at the lower end of the radial reaction section 2 . The height range of the axial reaction section is 300-800mm. The thickness range of the radial reaction section is 200-800mm.

[0044] The axial reaction section 1 includes an axial section cylinder and...

Embodiment 3

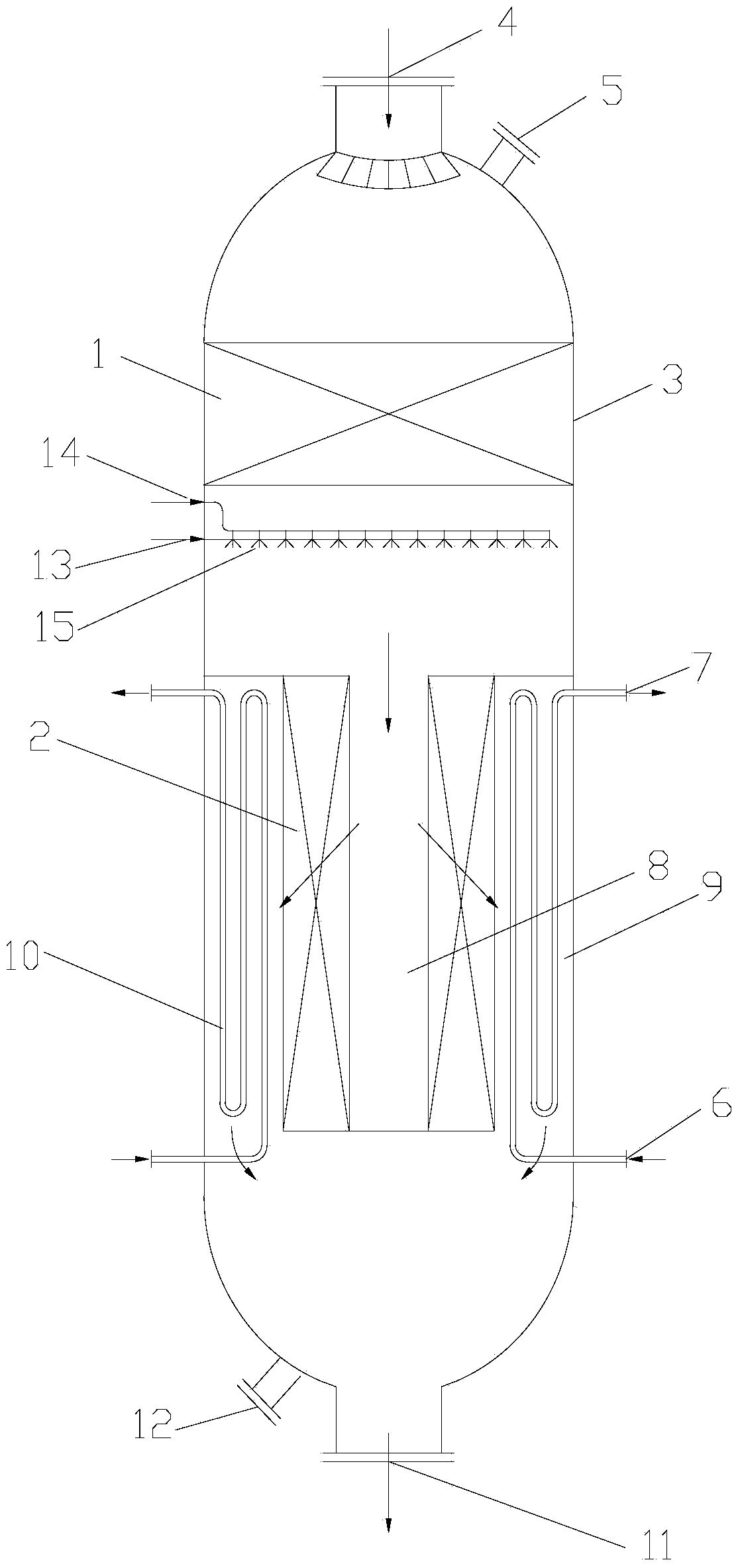

[0050] Such as image 3 Shown, a kind of axial radial composite fixed-bed catalytic reactor that is used for oxidative dehydrogenation of butene, comprises cylindrical reactor shell 3, the raw material gas inlet 4 that this reactor shell top is set, the bottom set The product gas outlet 11 and the feed gas inlet 4 are provided with a distributor, which is provided with an axial reaction section 1, a radial reaction section 2 and an inter-stage quenching section in the reactor shell 3, and the inter-stage The quenching section is located between the axial reaction section 1 and the radial reaction section 2; wherein the radial reaction section 2 is in the form of centrifugal flow, and the axial reaction section 1 is arranged at the upper end of the radial reaction section 2 . The height range of the axial reaction section is 300-800mm. The thickness range of the radial reaction section is 200-800mm.

[0051] The axial reaction section 1 includes an axial section cylinder and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com