Solid and liquid separator for materials

A solid-liquid separator and material technology, applied in filtration separation, separation methods, chemical instruments and methods, etc., can solve the problems of short service life, high maintenance, high replacement frequency, long feeding time, etc., to reduce production difficulty and cost, improve the production efficiency of the enterprise, and improve the effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

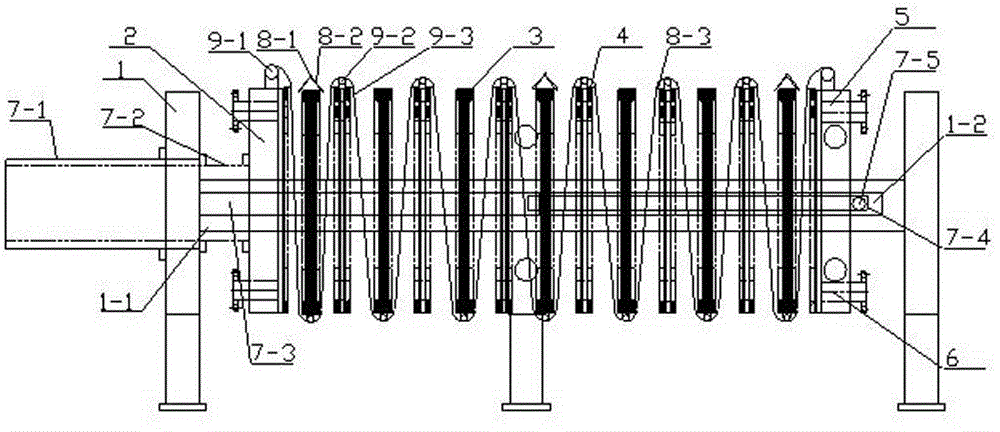

[0050] see figure 1 : The present invention comprises frame 1 and end platen 2, filter plate 3, middle platen 4, push-pull locking mechanism, filter cloth mechanism, filter cloth regeneration mechanism, material removal mechanism (not shown in the figure) that are arranged on frame 1 out). The aforementioned components and mechanisms will be described in detail below with reference to the accompanying drawings.

[0051] see figure 1 : Rack 1 is mainly composed of uprights at both ends (usually there are two uprights at each end, and the two are connected by reinforcing beams) and slide rails 1-1 fixed between the uprights at both ends along the length direction. 1-1 is provided with chute 1-2. A horizontal frame (not shown in the figure) is provided below the slide rail 1-1. In order to increase the strength of the rack 1, it may be considered to add an intermediate column at the middle of the slide rail 1-1.

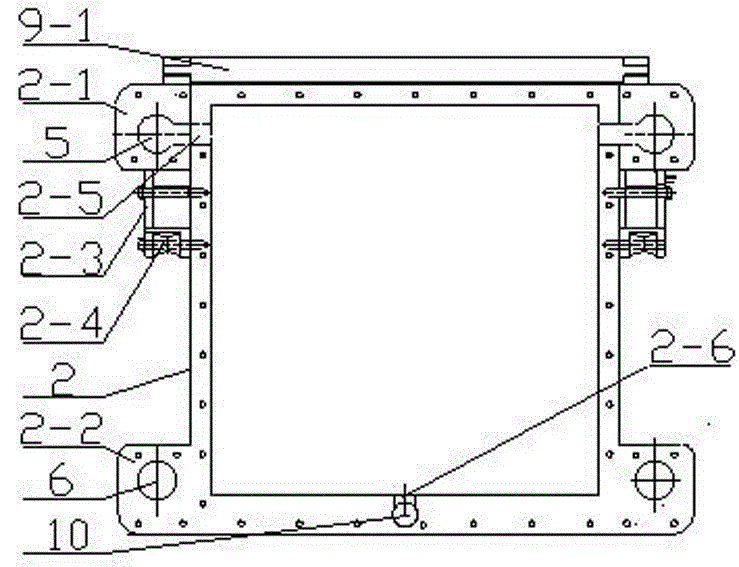

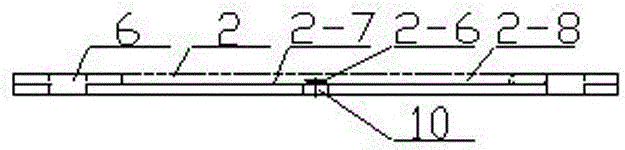

[0052] see figure 1 : The pressing plate is divided into an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com