Oral solid preparation of canagliflozin and preparation method thereof

A solid and filler technology, which is applied in the direction of medical preparations containing active ingredients, pill delivery, pharmaceutical formulations, etc., and can solve problems such as crystal transformation and poor compressibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

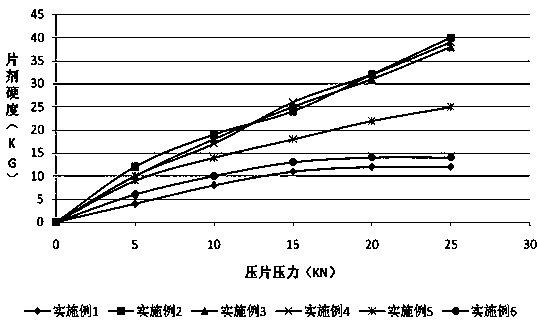

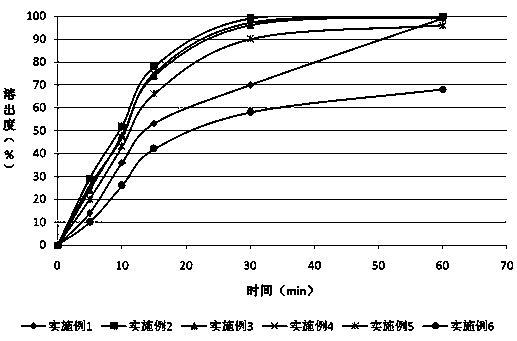

Embodiment 1~6

[0052] The prescription of embodiment 1~6 sees table 1:

[0053]

[0054] Preparation Process:

[0055] 1. Get the amorphous canagliflozin raw material of the above-mentioned volume average particle size for subsequent use;

[0056] 2. Pass the lactose, microcrystalline cellulose, croscarmellose sodium and magnesium stearate through an 80-mesh sieve for later use;

[0057] 3. Mix the bulk drug, lactose, microcrystalline cellulose, croscarmellose sodium of 70% prescription quantity and magnesium stearate of 70% prescription quantity of each embodiment, and the mixed material is added into dry process Dry granulation in the granulator, the prepared granules are mixed with 30% prescription amount of magnesium stearate and 30% prescription amount of croscarmellose sodium to obtain semi-finished products;

[0058] 4. Determine the content of the semi-finished product and calculate the tablet weight. The tablet weight was adjusted according to the content of the semi-finished ...

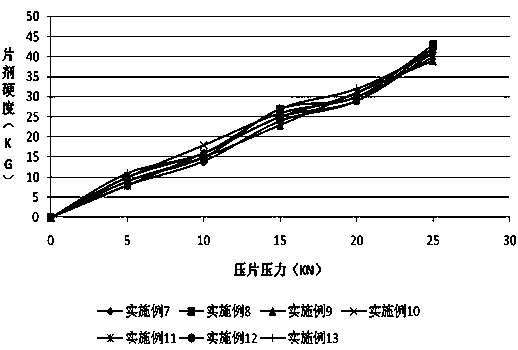

Embodiment 7~13

[0069] The prescription of embodiment 7~13 sees table 4:

[0070]

[0071] Preparation Process:

[0072] 1. Take the canagliflozin raw material with the above-mentioned volume average particle size for subsequent use;

[0073] 2. Lactose, mannitol, starch, pregelatinized starch, microcrystalline cellulose, croscarmellose sodium, crospovidone, carboxymethyl starch sodium, sodium lauryl sulfate, Silica and magnesium stearate are passed through an 80-mesh sieve for subsequent use;

[0074] 3. Mix all the excipients except silicon dioxide and magnesium stearate in the above prescriptions evenly, add the mixed materials into the dry granulator for dry granulation, and add the silicon dioxide of the respective prescription amount to the prepared granules Mix with magnesium stearate to get a semi-finished product;

[0075] 4. Determine the content of semi-finished products and calculate the tablet weight. According to the content of the semi-finished product, adjust the tablet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Volume average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com