OGS touch screen and manufacturing method thereof

A production method and touch screen technology, which are applied in the fields of instruments, electrical digital data processing, and data processing input/output processes, etc., can solve problems such as hardness not meeting customer requirements, many times of glass layer strengthening, affecting the service life of the whole machine, etc. , to achieve the effect that the line is not easy to break, the yield is high, and the production cost is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

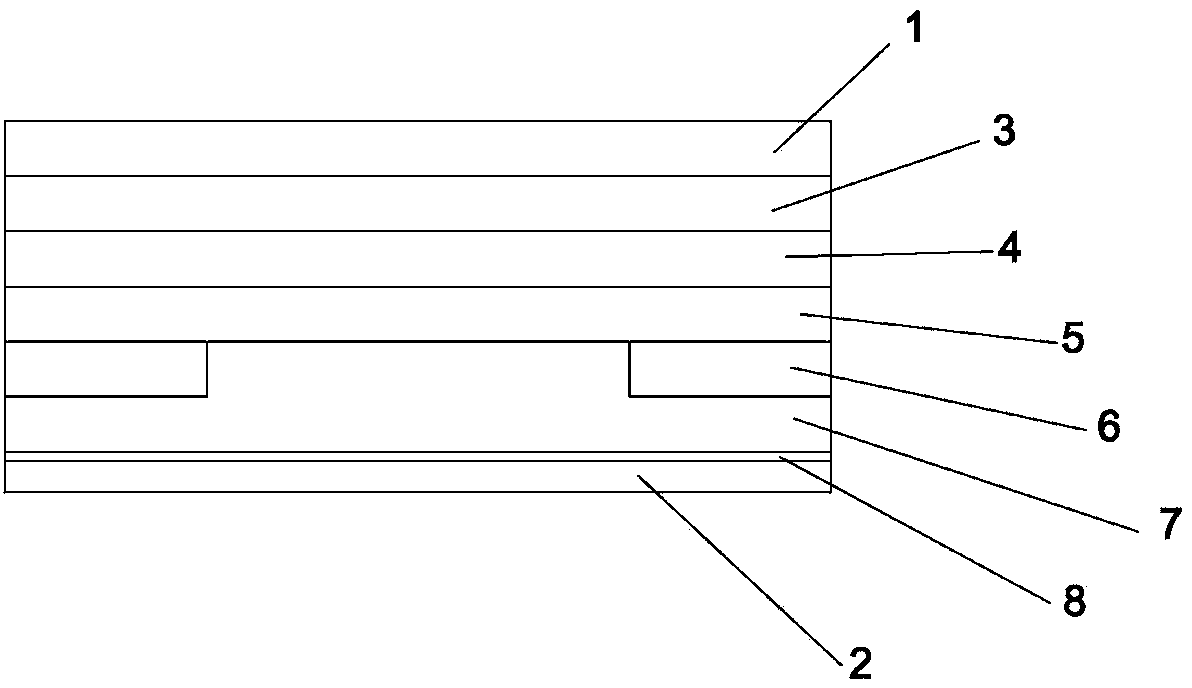

[0026] Embodiment one: if figure 1 As shown, an OGS touch screen includes an upper protective layer 1 and a lower protective layer 2, and between the upper protective layer 1 and the lower protective layer 2, a glass layer 3, an optical adhesive layer 4, and an optical grade PET layer are sequentially arranged from top to bottom. 5. The three-layer ink layer 6 and the printing surface are coated with a transparent conductive layer 7, and the printing surface is coated with a layer of photoresist layer 8.

[0027] In the meantime, the thickness of the glass layer 3 used in this embodiment is 0.7mm.

[0028] The thickness of the optical adhesive layer 4 used in this embodiment is 0.025 mm.

[0029] The optical grade PET layer 5 used in this embodiment has a thickness of 0.125mm.

[0030] The ink layer 6 used in this embodiment has a thickness of 0.013mm.

[0031] The upper protective layer 1 and the lower protective layer 2 used in this embodiment have a thickness of 0.05 mm....

Embodiment 2

[0033] Embodiment two: if figure 1 As shown, an OGS touch screen includes an upper protective layer 1 and a lower protective layer 2, and between the upper protective layer 1 and the lower protective layer 2, a glass layer 3, an optical adhesive layer 4, and an optical grade PET layer are sequentially arranged from top to bottom. 5. Four layers of ink layer 6 and the whole surface are plated with a transparent conductive layer 7, and the whole surface is coated with a layer of photoresist layer 8 on the lower surface of the transparent conductive layer 7.

[0034] In the meantime, the thickness of the glass layer 3 used in this embodiment is 0.8 mm.

[0035] The optical adhesive layer 4 used in this embodiment has a thickness of 0.1 mm.

[0036] The optical grade PET layer 5 used in this embodiment has a thickness of 0.08 mm.

[0037] The ink layer 6 used in this embodiment has a thickness of 0.01 mm.

[0038] The upper protective layer 1 and the lower protective layer 2 us...

Embodiment 3

[0040] Embodiment three: as figure 1 As shown, an OGS touch screen includes an upper protective layer 1 and a lower protective layer 2, and between the upper protective layer 1 and the lower protective layer 2, a glass layer 3, an optical adhesive layer 4, and an optical grade PET layer are sequentially arranged from top to bottom. 5. Five layers of ink layer 6 and the whole surface are plated with a transparent conductive layer 7, and the lower surface of the whole surface is coated with a layer of photoresist layer 8.

[0041] In the meantime, the thickness of the glass layer 3 used in this embodiment is 1.5 mm.

[0042] The thickness of the optical adhesive layer 4 used in this embodiment is 0.2 mm.

[0043] The optical grade PET layer 5 used in this embodiment has a thickness of 0.15 mm.

[0044] The ink layer 6 used in this embodiment has a thickness of 0.04mm.

[0045] The upper protective layer 1 and the lower protective layer 2 used in this embodiment have a thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com