High-temperature ultralow permeability measuring instrument

An ultra-low permeability, measuring instrument technology, applied in permeability/surface area analysis, measuring devices, scientific instruments, etc., can solve the problems of high temperature and ultra-low permeability measurement and high manufacturing costs, and achieve low development costs and reliability. High performance and simple overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Below in conjunction with accompanying drawing, the present invention is described in further detail:

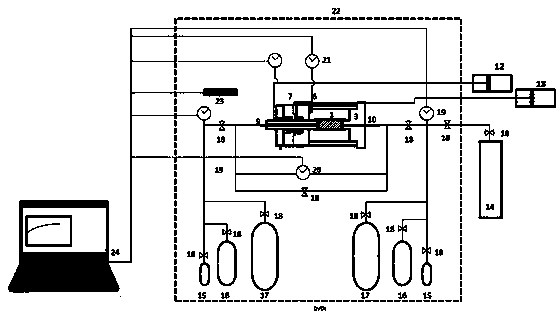

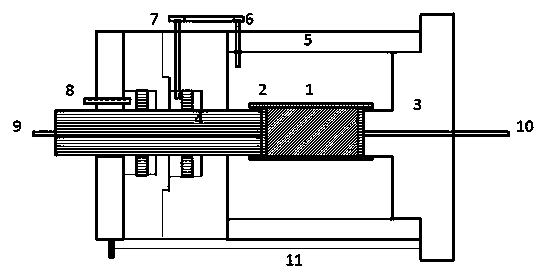

[0021] A high-temperature ultra-low permeability measuring instrument ( figure 1 ), which consists of triaxial pressure chamber, displacement sensor 11, hydrostatic pressure loading pump 13 and bias loading pump 12, constant current / constant pressure control pump 14, small volume gas storage tank 15, medium volume gas storage tank 16, large volume It is composed of gas storage tank 17, pore pressure sensor 19, upstream and downstream pore pressure deviation sensor 20, oil pressure sensor 21, temperature sensor 23, high temperature control box 22, and data acquisition system 24 and other components. The connection relationship is: the triaxial pressure chamber is connected to the hydrostatic pressure loading pump 13 and the bias loading pump 12 respectively through the oil pipeline, and is connected to the constant flow / constant pressure control pump 14 through the gas...

experiment example 1

[0028] The equipment was used to measure the permeability of mudstone. The test plan was to apply a hydrostatic pressure of 12MPa to a cylindrical sample with a height of 76mm and a diameter of 38mm. The temperature was controlled at 60°C, and then the permeability was measured. The test results show that it takes 15 minutes for the temperature to be loaded from room temperature to 60°C, the temperature of the whole system is constant at 60.2°C, the temperature fluctuation is less than 0.2°C, the hydrostatic pressure is loaded, and the constant flow / constant pressure control pump (ISCO 500D) is used Pressurize the air storage tank of the smallest container, and then implement pulse measurement. After 12 hours, the system pressure is stable, and the measured permeability is 10 -22 m 2 .

[0029] For accurate measurements, the device is leak tested. For a metal sample with a diameter of 38mm and a height of 76mm, the pulse method is used to conduct a penetration test to observ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com