Microwave heat-energy tentering setting machine

A tenter setting machine and heating setting technology, applied in heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve problems such as greenhouse effect affecting the atmosphere, fabric quality defects, waste of energy consumption, etc., to avoid thermal energy. Waste, less power wastage, and the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solutions of the present invention will be further specifically described below through specific embodiments and in conjunction with the accompanying drawings.

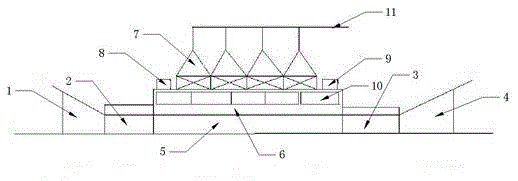

[0020] like figure 1 As shown, a microwave thermal energy stenter setting machine includes a cloth feeding device (1), a tentering area (2), a heating and setting device, a natural cooling area (3), and a cloth output device (4), and the heating and setting device It includes a heating and shaping area (5) and a microwave heating device, characterized in that the microwave heating device includes a main heater (6), a plurality of gas collecting hoods (7) arranged above the main heater, and a waveguide (8) As well as the water load device (9), energy leakage suppressors (10) are provided at each opening behind the heating and shaping area. Wherein the top of the heating and shaping area is also provided with a dehumidifying device 11, and the number of air collecting hoods is 6. The main heater i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com