Device for guaranteeing normal operation of sacrificial anode

A sacrificial anode, normal operation technology, applied in the field of anti-corrosion, can solve the problem of anode passivation or even reversal, affect the effect and life of cathodic protection, increase anode and other problems, to solve the current efficiency drop and possible passivation or reversal, to ensure the use effect and age, reducing replacement and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

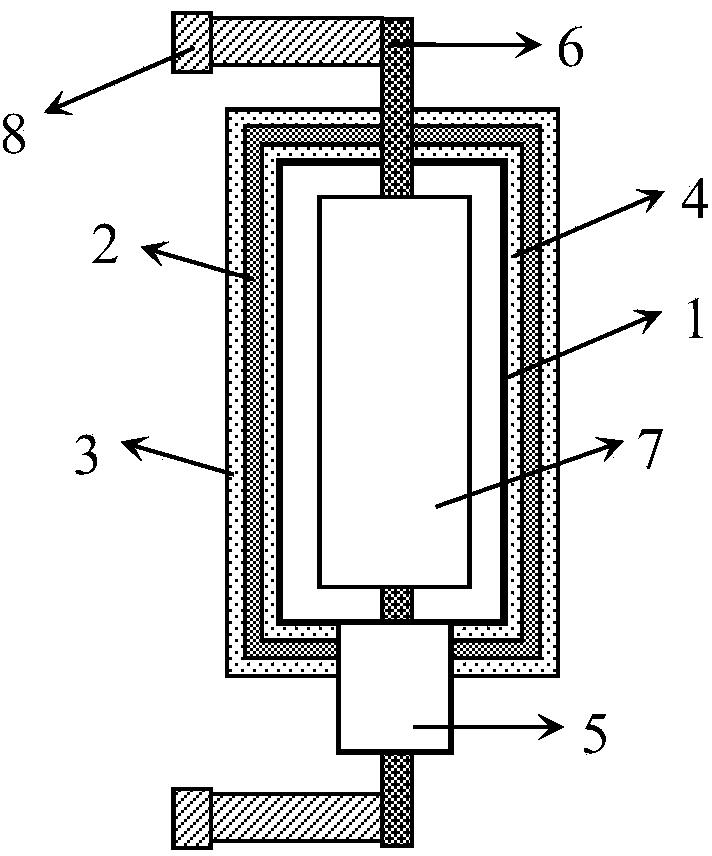

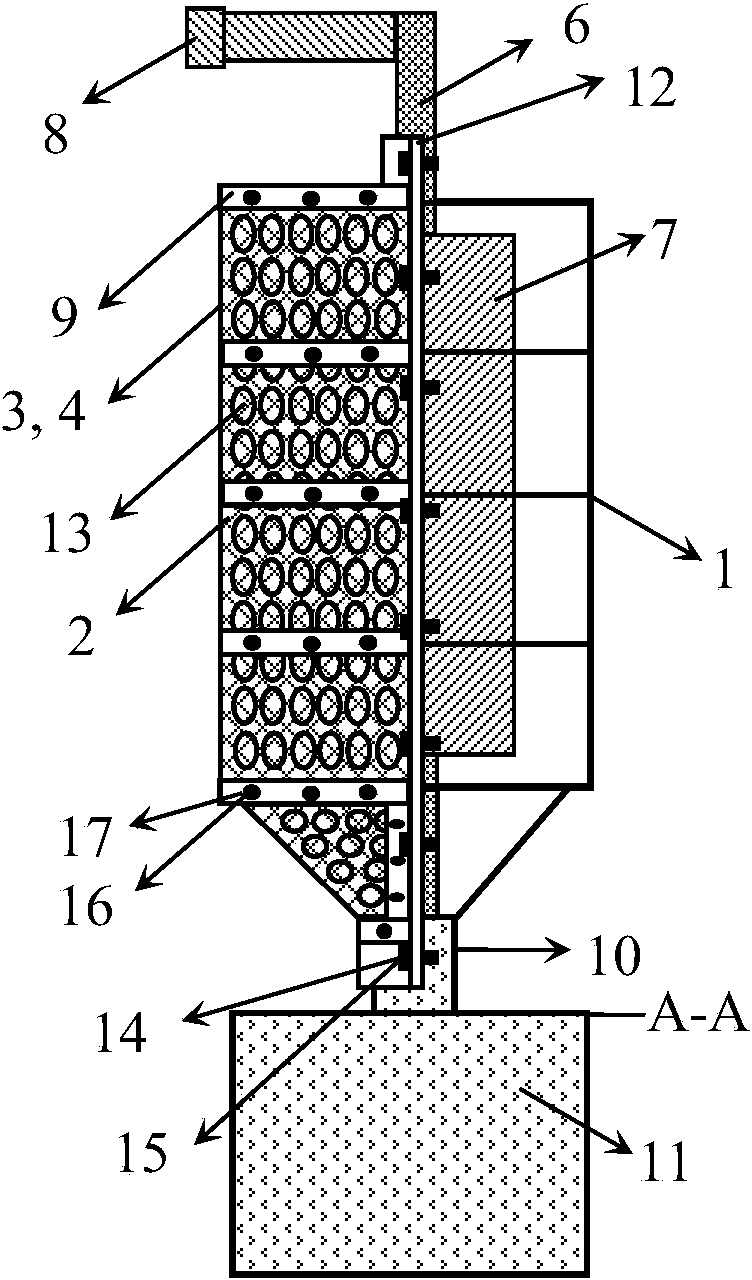

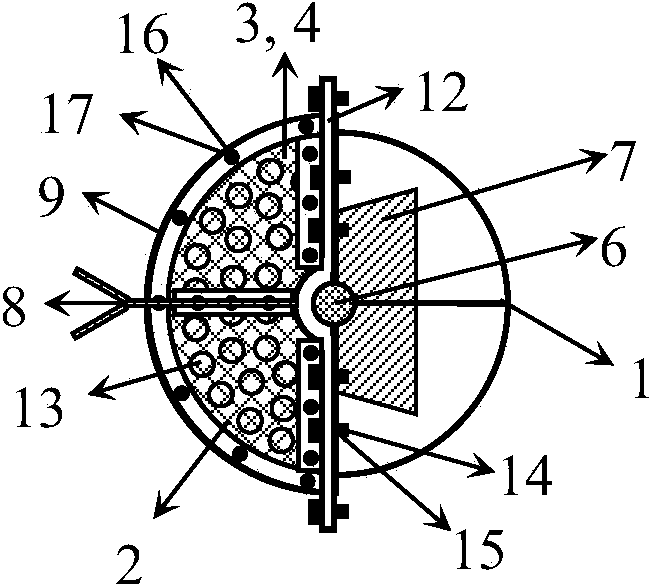

[0039] Example 1 A device for ensuring the normal operation of sacrificial anodes for the sea mud environment

[0040]The device in embodiment 1 is suitable for long strip or trapezoidal sacrificial anodes vertically installed in sea mud environment, such as anodes in sea mud installed by steel pipe piles of structures such as docks and sea-crossing bridges. refer to Picture 1-1 , is a structural diagram of a device for ensuring the normal operation of sacrificial anodes for the sea mud environment. The device of the present invention includes a steel skeleton 1, a polymer hole sleeve 2, an outer net cover 3, an inner net cover 4, a fixing bar 9, a sewage channel 10, a sewage storage tank 11, a flange 12, a through hole 13, bolts, nuts and gaskets Group A14, bolt hole A15, bolt nut washer group B16, bolt hole B17. Among them, the steel skeleton 1 has two matching components, which are symmetrically welded on the anode steel core 6 to form a cylindrical skeleton; the polymer...

Embodiment 2

[0055] Example 2 A device for ensuring the normal operation of sacrificial anodes aimed at the adhesion of marine organisms in seawater

[0056] The device in embodiment 2 is suitable for long-strip or trapezoidal sacrificial anode bodies vertically installed in seawater, such as anodes installed in seawater by steel pipe piles of structures such as piers and sea-crossing bridges. The main structure of the device of embodiment 2 is basically the same as the device of embodiment 1, but the sewage device of embodiment 2 is changed to some extent.

[0057] refer to Figure 3-1 , is a structural schematic diagram of a device for ensuring the normal operation of sacrificial anodes aimed at the adhesion of seawater in seawater. Wherein, the inner diameter of the sewage discharge device 18 of the sewage discharge device in embodiment 2 matches the sewage discharge channel 19, and consists of two matched components. Both components have sewage discharge holes 23 on their bottom surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com