The preparation method of cortisone acetate

A cortisone acetate and reaction technology, applied in the field of chemical synthesis of steroid hormone drugs, can solve the problems of high starting raw material prices and high process costs, and achieve the effects of reduced process costs, high yields, and low prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

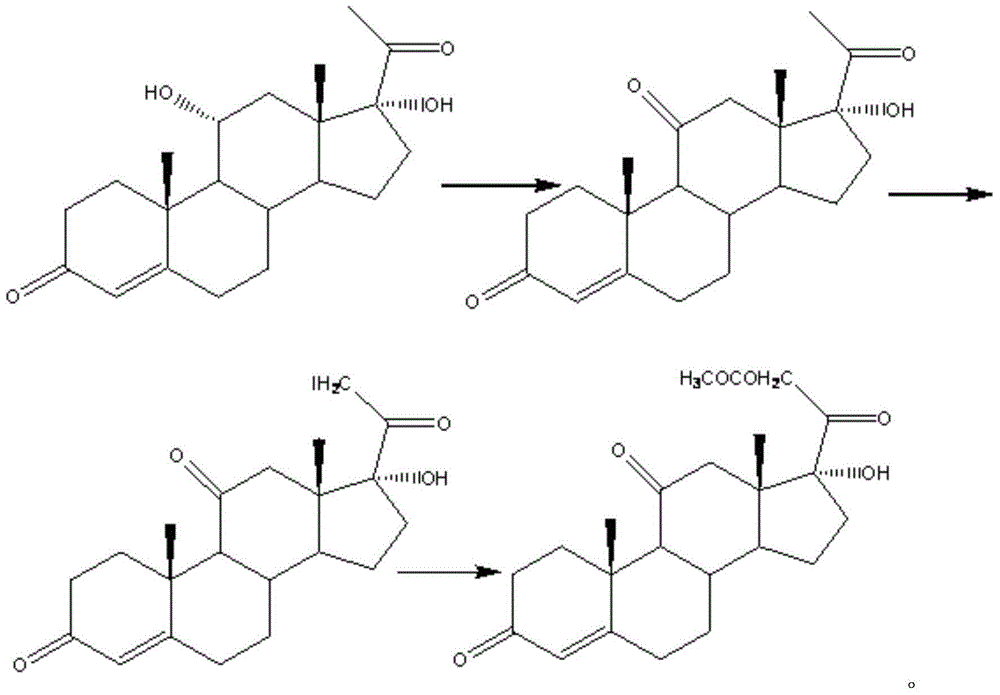

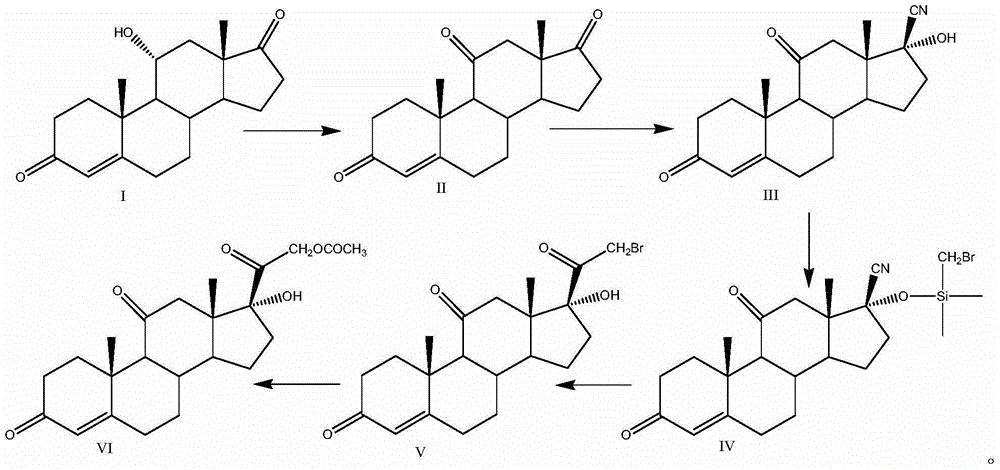

Image

Examples

Embodiment 1

[0024] oxidation reaction

[0025] At room temperature, add 180ml of glacial acetic acid and 50ml of manganese acetate aqueous solution with a mass concentration of 50% to a clean and dry 500ml four-necked round-bottomed flask equipped with a thermometer, reflux condenser, and mechanical stirring, and add 100.0g of compound I under stirring, and the system Lower the temperature to 40 to 50°C, control the temperature at 40 to 50°C, and add 50ml of chromium trioxide aqueous solution with a mass concentration of 50% dropwise. After the dropwise addition was completed, the reaction was carried out for 2 hours. TLC followed the reaction until no raw material remained. The system was lowered to room temperature, and the reaction system was added dropwise to 2L of purified water, a large amount of solids were precipitated, and the stirring was continued for 2 hours. The system was suction-filtered, the filter cake was washed with water until it was neutral, and dried at 50°C to obt...

Embodiment 2

[0034] oxidation reaction

[0035]At room temperature, under the protection of nitrogen, add 200ml of acetone and 50ml of manganese acetate solution with a mass concentration of 40% to a clean and dry 500ml four-necked round-bottomed flask equipped with a thermometer, a reflux condenser, and mechanical stirring, and add 100.0g of the compound under stirring Ⅰ. Cool the system down to 40-45°C, control the temperature at 40-50°C, and add 50ml of chromic anhydride aqueous solution with a mass concentration of 60% dropwise. After the dropwise addition was completed, the reaction was carried out at a constant temperature for 3 hours. TLC followed the reaction until no raw material remained. The system was cooled to room temperature. The reaction system was added dropwise to 3 L of purified water, a large amount of solids were precipitated, and the stirring was continued for 2.5 hours. The system was suction-filtered, the filter cake was washed with water until neutral, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com