Preparation process and quality detection method of polysaccharide-iron complex

A quality detection method and complex technology, which are applied in the preparation of sugar derivatives, sugar derivatives, sugar derivatives, etc., can solve the problems of unsatisfactory production yield and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0059] Experimental example 1 The present invention polysaccharide iron complex preparation method operation process and technological condition experiment

[0060] 1. Ingredients:

[0061] Planned output: 33kg;

[0062] 1) Raw material A: ferric chloride solution (32%)

[0063] Weigh 93 kg of ferric chloride into a dissolving tank, add 194 kg of purified water, dissolve, and set aside.

[0064] 2) Raw material B: sodium hydroxide solution (15%)

[0065] Weigh 57kg of sodium hydroxide (solid alkali) into a dissolution kettle, add 310kg of purified water, dissolve, and set aside.

[0066] 3) Raw material C: syrup (solid content 25%)

[0067] Weigh 97.75 kg of syrup (50% solid content) into a dissolving kettle, add 97.75 kg of purified water, dissolve, and set aside.

[0068] 2. Reaction process

[0069] 1) Add the prepared syrup solution into a 1000L reaction tank, start stirring, stir for 10-15 minutes to make it evenly mixed, and pour tap water into it to cool;

[0070...

experiment example 2

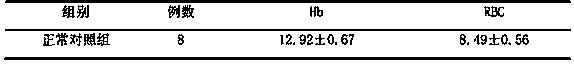

[0090] Experimental Example 2 Comparison experiment of the anti-iron-deficiency anemia effect of the polysaccharide-iron complex obtained by the preparation method of the present invention

[0091] 1. Purpose of the experiment

[0092] The iron-deficiency anemia mouse animal model was reproduced by the method of low-iron feed feeding and blood loss model, to investigate the pharmacodynamic effect of the polysaccharide-iron complex prepared by the preparation method of the present invention.

[0093] 2. Materials and methods

[0094] 2.1. Materials

[0095] 2.1.1 Drugs:

[0096] The polysaccharide-iron complex administration group prepared by the preparation method described in Example 1 was three groups, which were high-dose group, middle-dose group and low-dose group. All provided by Natural Medicines Laboratory.

[0097] Refinon, produced by the American branch of Schwartz Pharmaceutical Group, Germany, product batch number 435260101

[0098] Each drug administration gr...

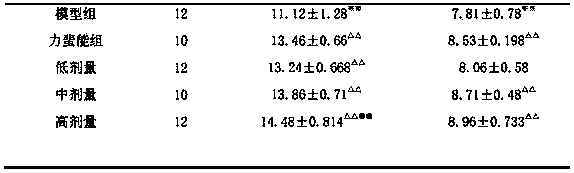

experiment example 3

[0124] Experimental Example 3 The control of the first alkali addition of the polysaccharide-iron complex of the present invention

[0125] In production research engineering, the yield of polysaccharide-iron complex is sometimes high, sometimes low, and sometimes even the final product cannot be obtained. After a lot of experimental research, it was unexpectedly found that the control of the first addition of lye is a key link. If the addition is too fast or excessive, the polysaccharide-iron complex cannot be formed later. After a lot of experiments, it was found that 220-250 parts by weight (preferably 190-210 parts by weight, 244 parts by weight, 225 parts by weight) of 10%-20% aqueous sodium hydroxide solution was added to the reaction tank within 60-90 minutes During the process, the reaction temperature is controlled at 15-25°C. After the feeding is completed, the stirring is continued until the reaction is completed within the above range, and finally the yield of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com