Capacitor

A capacitor and electrode plate technology, applied in the field of capacitors, can solve problems such as shortening the service life, and achieve the effects of flexible processing, reduction of self-inductance, and cost reduction

Active Publication Date: 2014-03-12

SOSHIN ELECTRIC COMPANY LIMITED

View PDF5 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At this time, the capacitor element and the connector self-heat and tend to shorten their service life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

example

[0084] The capacitors according to Comparative Examples and Inventive Examples 1 to 8 were measured for their capacitor inductances using a network analyzer.

[0085] The structures of the capacitors according to Comparative Examples and Inventive Examples 1 to 8 are as follows:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

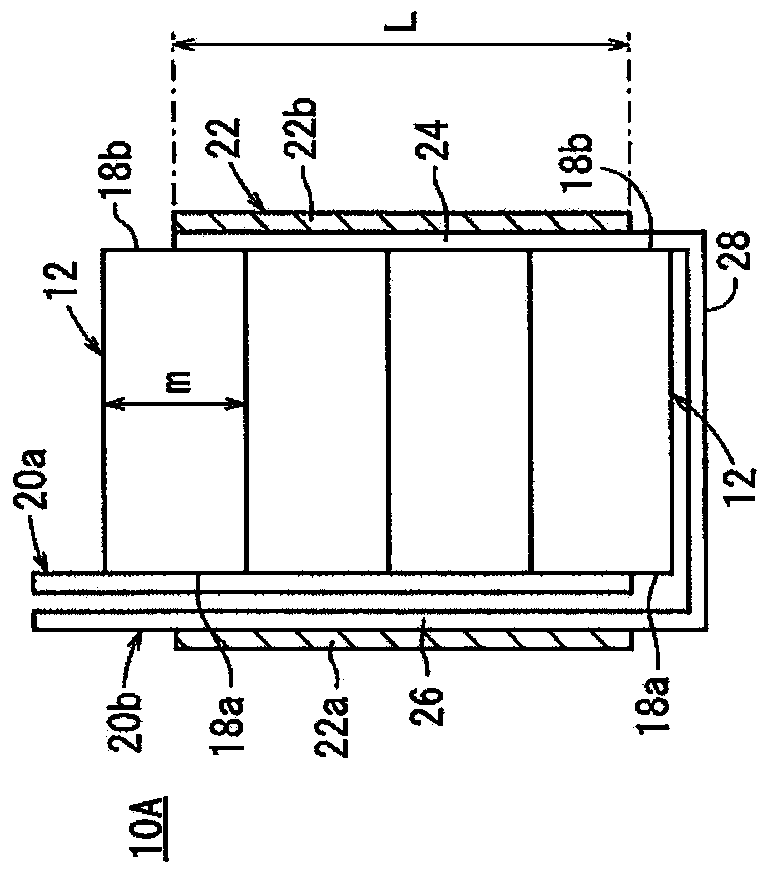

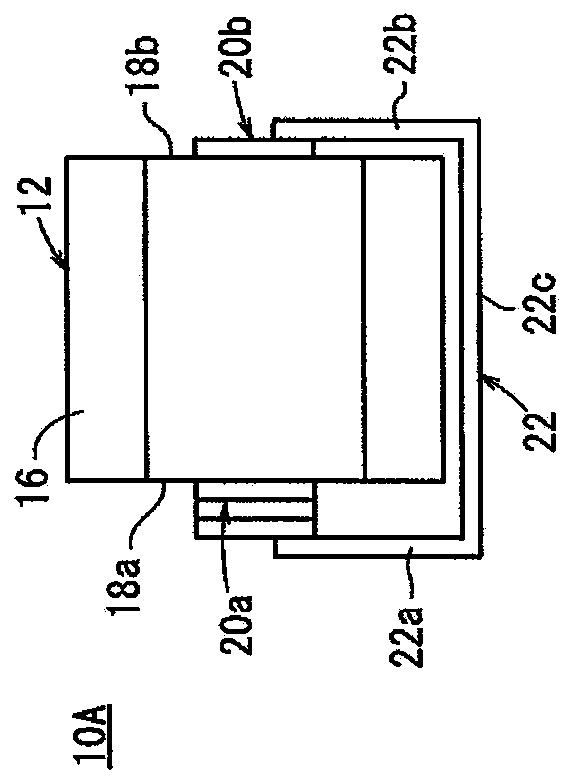

This capacitor has: a single capacitor block (14) provided with a plurality of capacitor elements (12) electrically connected in parallel, each of said capacitor elements (12) having a terminal part (18a, 18b) on each end; a first electrode plate (20a) that electrically connects the first terminal parts (18a) of the capacitor elements (12); a second electrode plate (20b) that electrically connects the second terminal parts (18b) of the capacitor elements (12) and continues on to the side where the first terminal parts (18a) are; and at least one bypass electrode plate (22) that electrically bypasses the second electrode plate (20b).

Description

technical field [0001] The present invention relates to a capacitor using a capacitor block composed of a plurality of capacitor elements electrically connected in parallel with each other. Background technique [0002] Generally, a capacitor having a large capacitance exceeding 100 μF employs a capacitor block, and in order to provide the required electrostatic capacitance, by preparing a plurality of capacitor elements each having a capacitance of less than 100 μF or about 100 μF and using a connector such as a flat-strand copper wire or the like Capacitor elements are connected in parallel to each other to produce a capacitor block. Some capacitors have a plurality of such capacitor blocks connected in parallel with each other. [0003] When such a capacitor is used as a smoothing capacitor in a power converter such as an inverter or the like, a pulsating current having a carrier frequency or the like from the inverter flows through the capacitor. At this time, the capa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H01G4/228H01G4/38

CPCH01G4/385H01G4/232H01G2/08H01G4/38H01G4/248H01G4/228

Inventor 依田武治立山健一柳桥清一加藤芳邦

Owner SOSHIN ELECTRIC COMPANY LIMITED

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com