Novel electric brush

A brush, a new type of technology, applied in the direction of circuits, collectors, electrical components, etc., can solve problems such as brush stuck, achieve smooth rotation, low no-load starting voltage, and meet the design requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

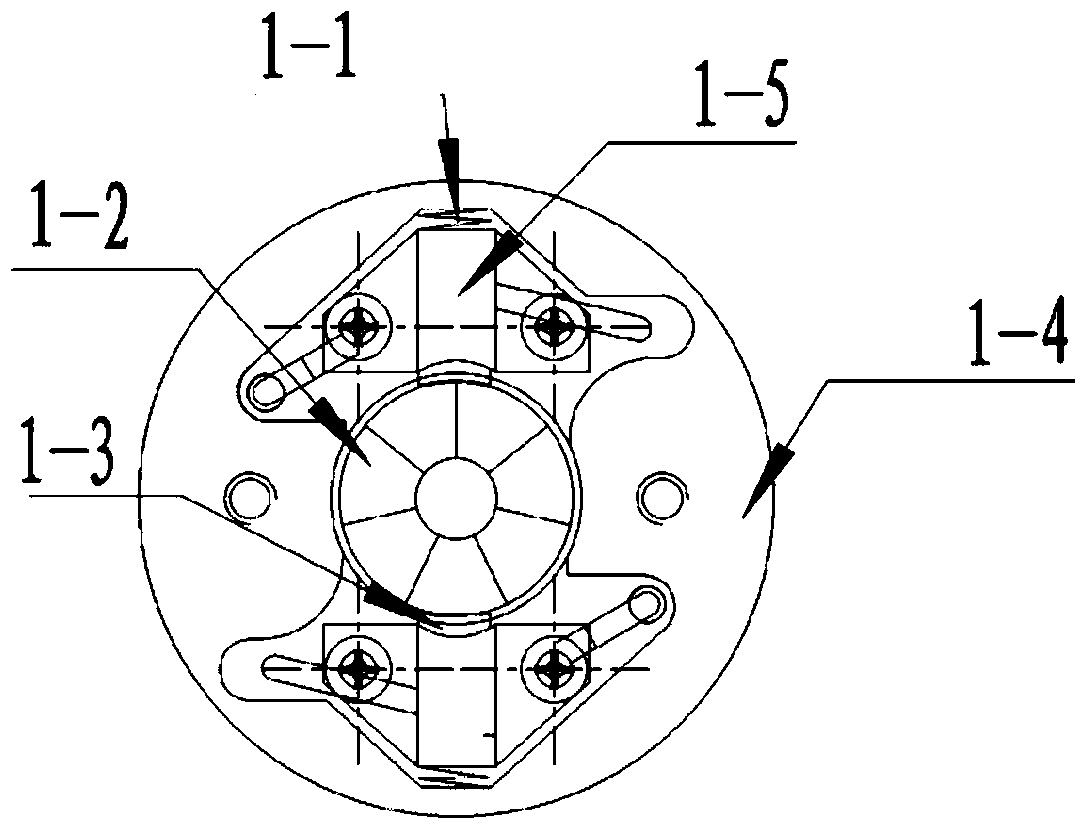

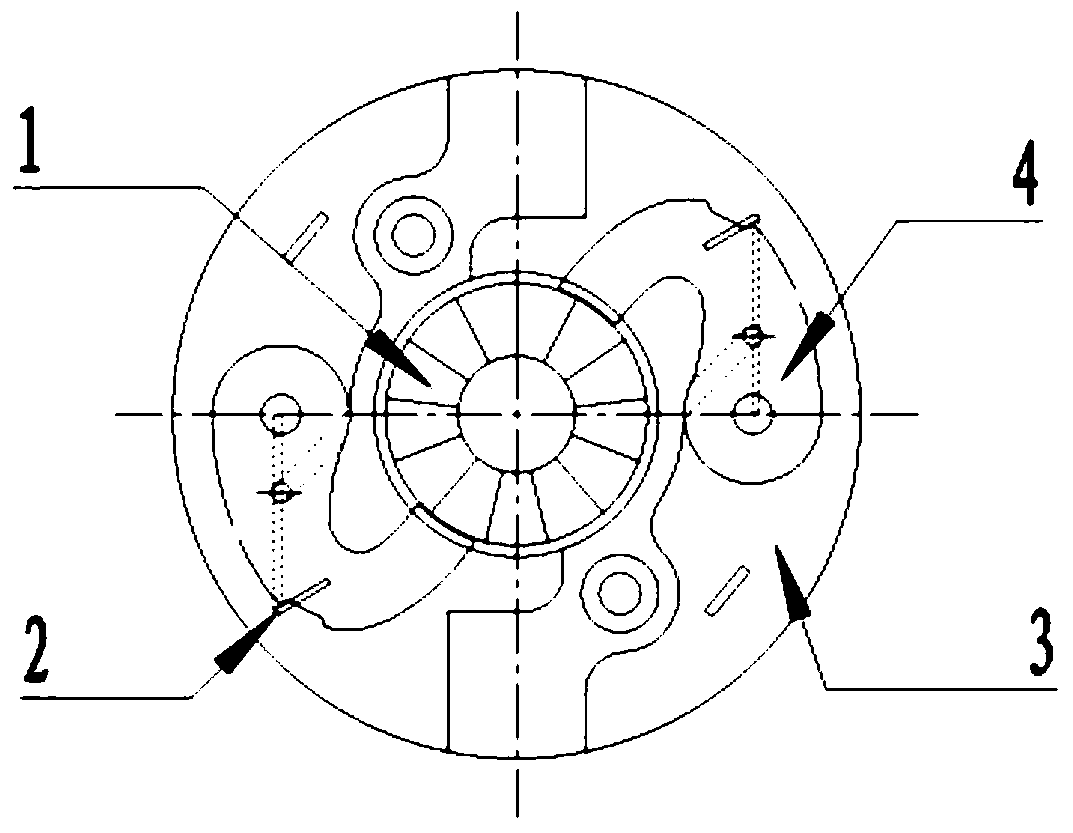

[0011] Such as figure 2 What is shown is a specific embodiment of the invention. The structure of the brush 4 is designed as a hook, one end is in contact with the commutator 1, and the other end is directly riveted on the brush box 3 through a rivet, and rotates around the riveting point, and the outer hook protruding from one end of the spring 2 presses on the electric brush box. The highest point of the brush hook, so that the brush acts on the commutator through the torsion of the spring. In the design, it is required to ensure that the contact between a pair of brushes and the commutator is 3 or 4 pieces when the hollow cup motor is rotating. The torsion plate and the spring have good torsion consistency, so that the no-load starting voltage of the coreless motor is small. Compared with traditional brushes, this new type of brush has no brush box and is a brushless brush with high space utilization, long working stroke and long working life, which is conducive to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com