Garbage clearing and transporting device for high-rise building construction floor

A high-rise building and garbage technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of construction garbage stuck, hidden safety hazards, heavy weight, etc., and achieve the effect of promoting the whereabouts of garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

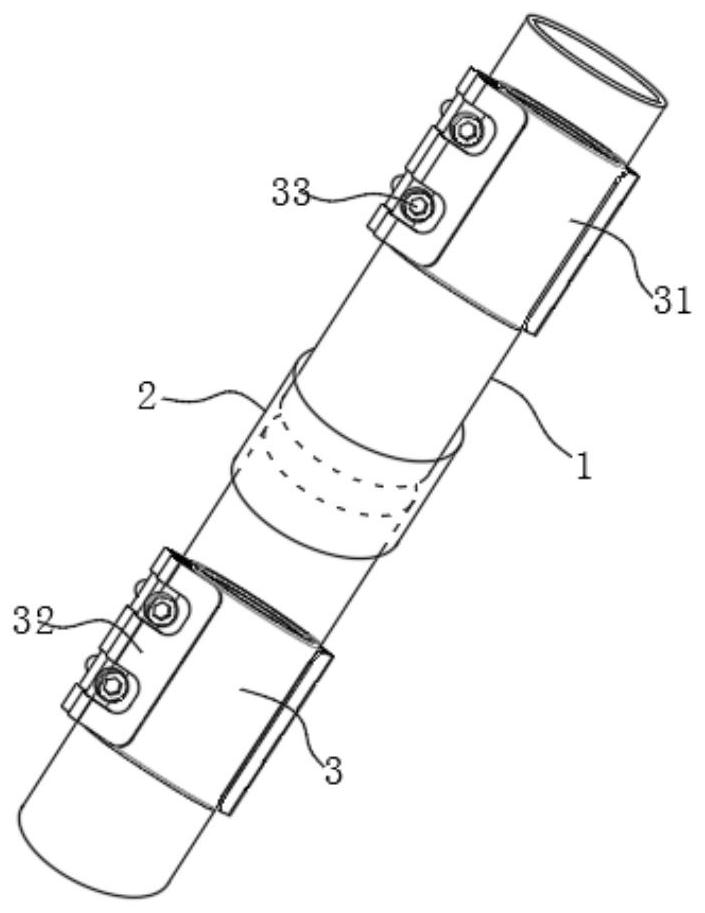

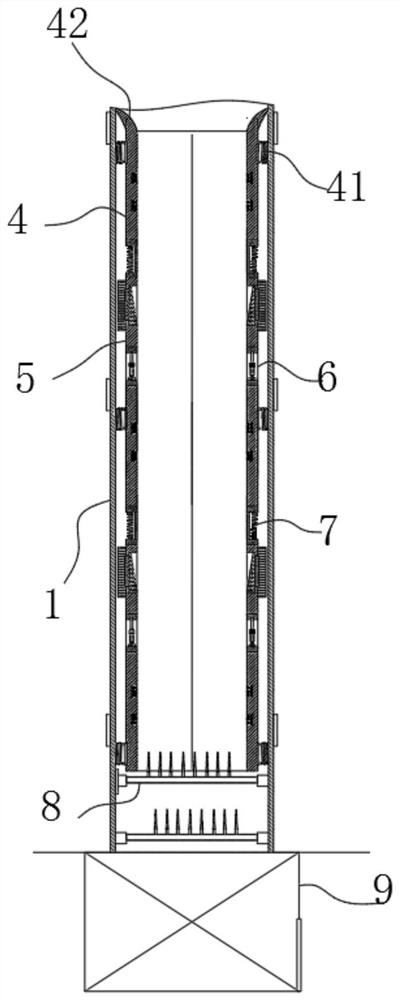

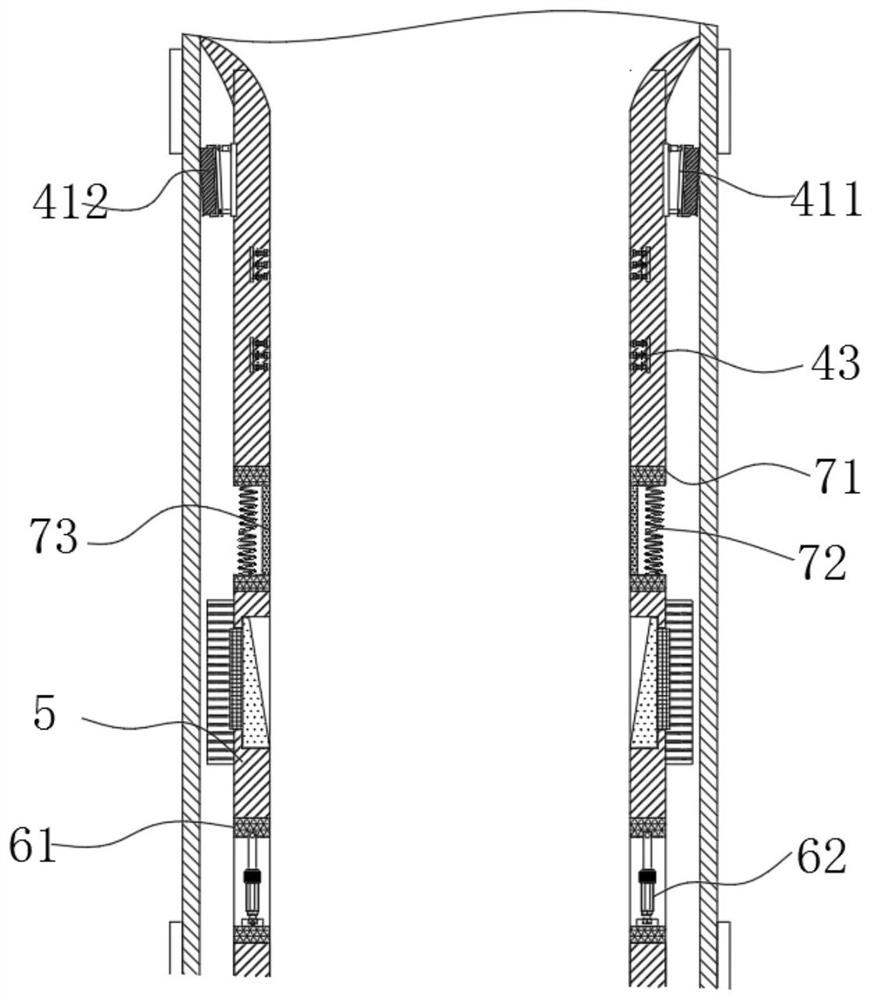

[0037] see Figure 1~4 , in an embodiment of the present invention, a garbage removal device for a high-rise building construction floor, comprising:

[0038] At least two external pipes 1, and two adjacent external pipes 1 are detachably connected by a connecting pipe 2. In practical applications, the number of external pipes can be further determined according to the height of the construction floor of a high-rise building. Pipe 2 can be a rigid threaded connection pipe or a flexible pipe;

[0039] The anchoring mechanism 3 is correspondingly sleeved on the outer connecting pipe 1, and the outer connecting pipe 1 can be anchored in the building wall through the anchoring mechanism 3, specifically, as figure 1 , the anchoring mechanism 3 includes two semi-circular anchoring pipes 31, the anchoring pipes 31 are fixedly connected with anchoring seats 32, and utilize the anchor bar 33 to pass through the two anchoring seats 32 and embed them in the building wall to realize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com